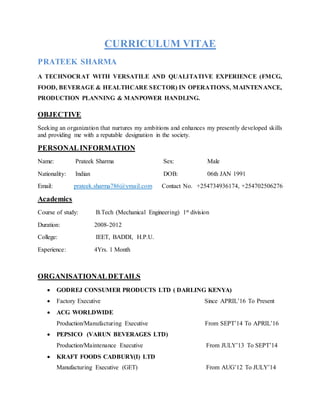

Prateek Sharma is seeking a position that allows him to further develop his skills. He has a B.Tech in Mechanical Engineering and over 4 years of experience in operations, maintenance, production planning and manpower handling in the FMCG sector. His experience includes roles at Godrej Consumer Products, ACG Worldwide, PepsiCo, and Kraft Foods Cadbury. He is skilled in production planning, quality control, safety management, people management, cost control, and documentation.