Vageesh Kumar has extensive experience leading production operations for consumer packaged goods companies in Africa and India. Some key highlights of his career include:

- Starting up and leading production for a toothpaste, cosmetics and food manufacturing plant in Nigeria.

- Growing production from 100MT to 450MT of toothpaste over 8 years as Production Manager for Chemie & Cotex in Tanzania, making it the largest toothpaste manufacturer in East Africa.

- Successfully installing production lines for cream and lotion plants in record time in Tanzania and Ethiopia.

- Receiving numerous commendations and awards for exceeding performance targets from management and machinery suppliers.

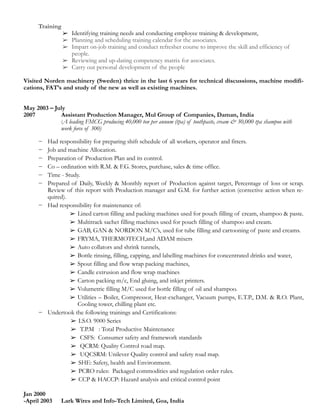

His responsibilities have included overseeing all production