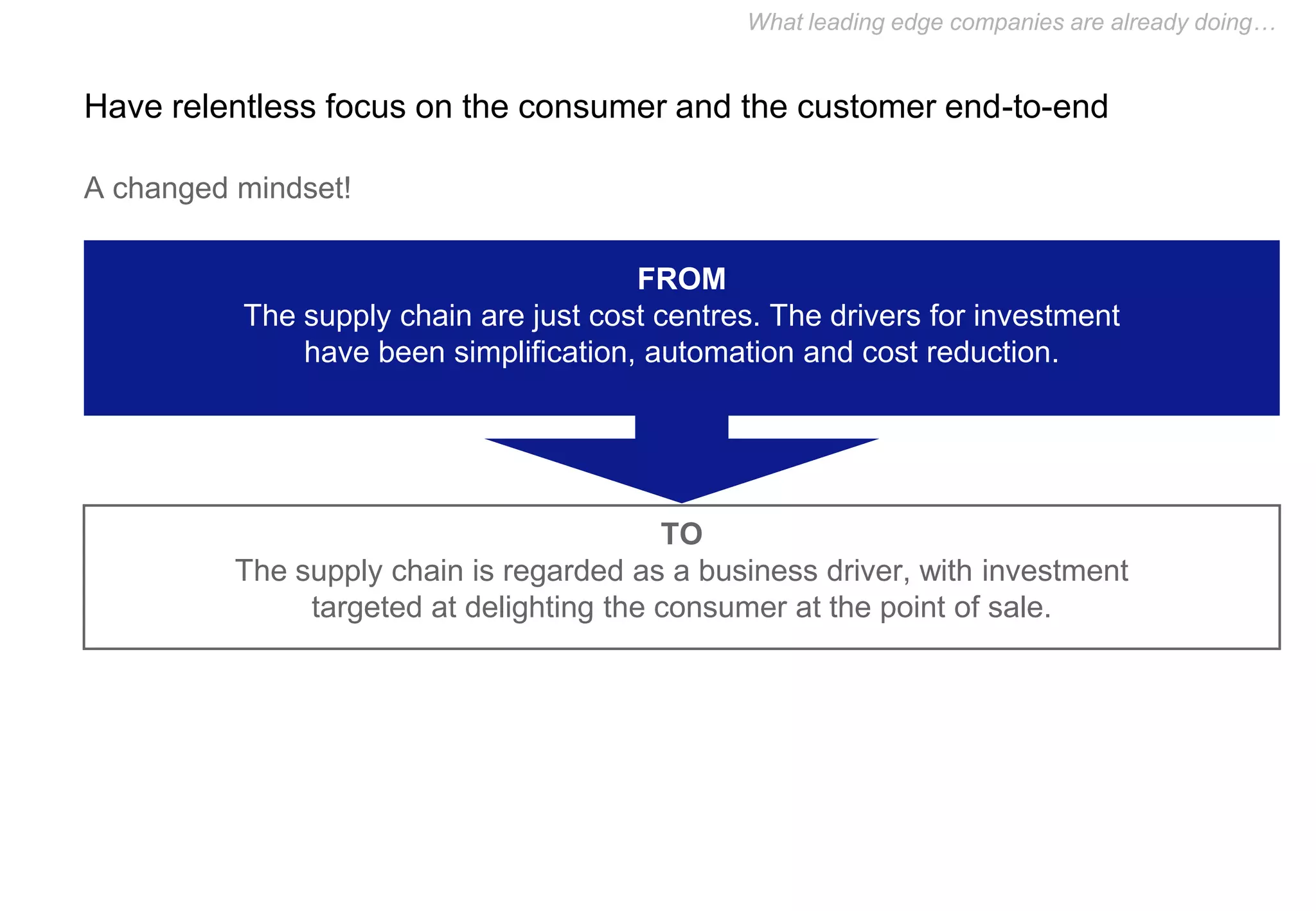

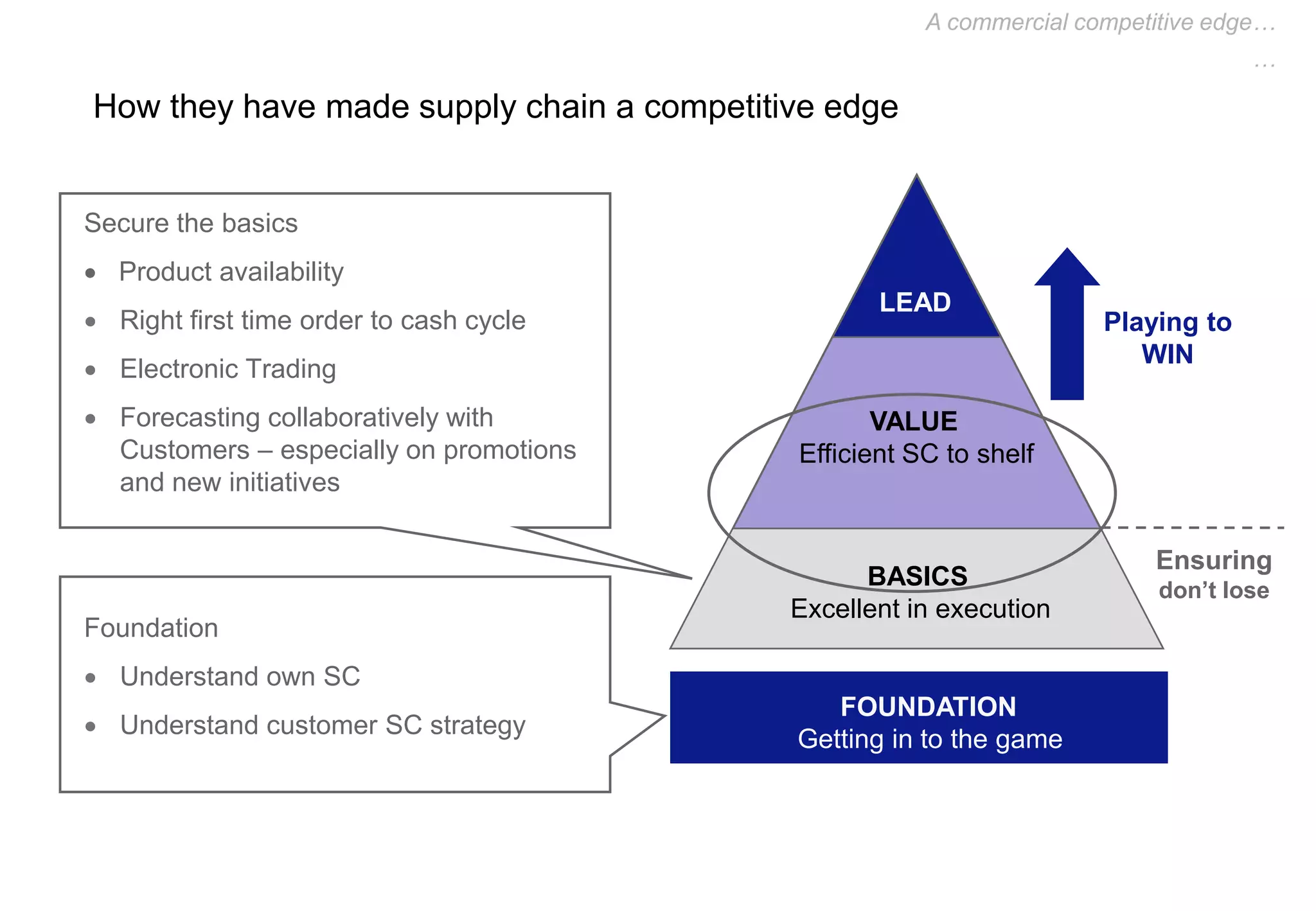

Leading companies are focusing their supply chains on the customer and consumer. They design supply chains from the shelf back to ensure they are winning customers and consumers. They also balance global scale with local responsiveness to meet varied customer needs. This allows them to gain a competitive edge through customer service innovations, flawless execution, joint supply chain value creation, and responsiveness. In real life, companies focus on service, work closely with customers, and ensure flexibility to pursue opportunities and provide differentiated products and services.