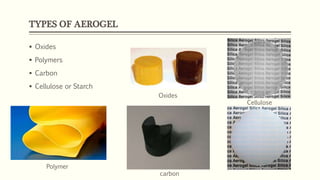

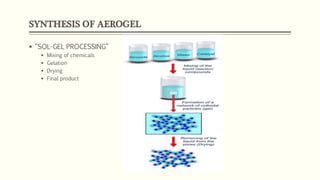

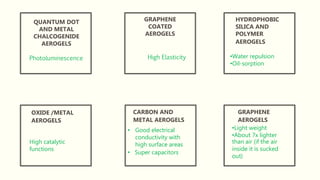

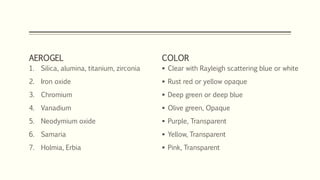

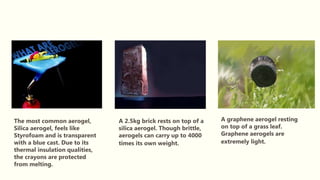

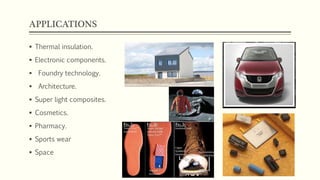

Aerogel is an ultra-light synthetic material derived from a gel, in which the liquid component of the gel has been replaced with a gas. It is 95-99% air, but can support loads 2000 times its own weight. Common types include silica, carbon, polymer and cellulose aerogels. Aerogel has applications in thermal insulation, electronics, architecture and more due to its low density, high porosity, low thermal conductivity and sound absorption. It has potential as an insulation material for building walls and roofs to improve energy efficiency. However, high production costs and poor mechanical strength currently limit its widespread use.