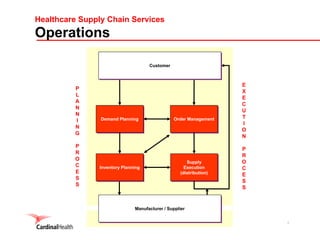

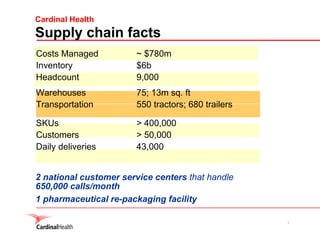

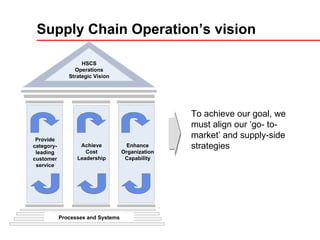

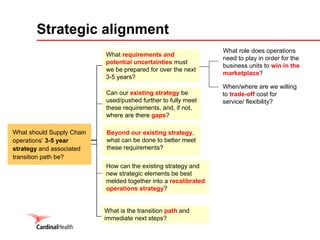

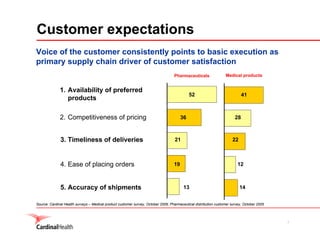

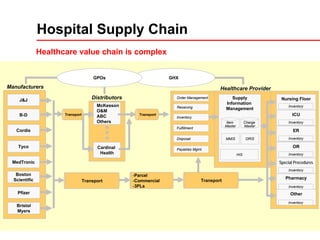

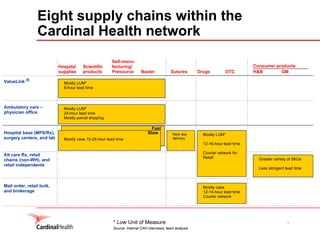

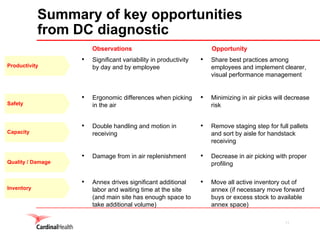

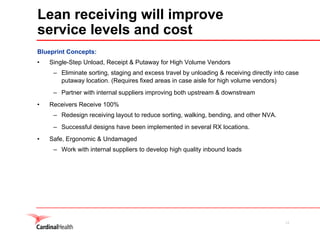

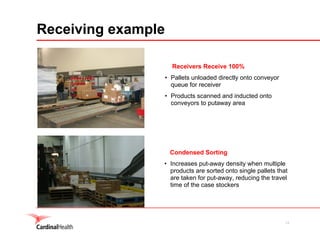

Cardinal Health aims to create a leaner supply chain by enhancing customer service, reducing costs, and improving operational capabilities. The document details a strategic vision focused on aligning marketing and supply-side strategies, addressing customer expectations on order accuracy and delivery timeliness, and improving productivity through best practices. Key opportunities identified include optimizing inventory handling and receiving processes to enhance service levels and efficiency across the distribution network.