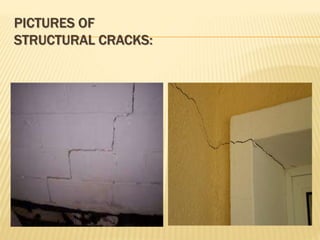

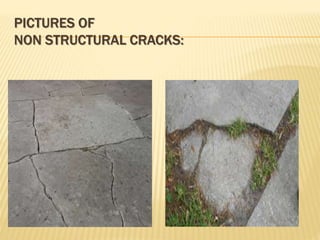

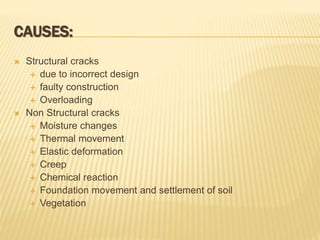

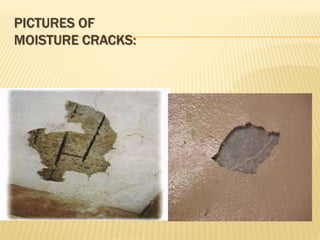

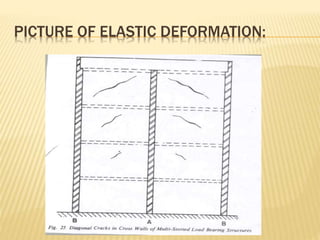

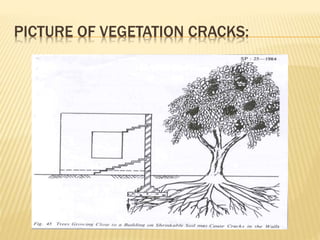

Shahid Ali presented on different types of cracks in buildings. There are two main types: structural cracks, which refer to cracks in the core framework of the building and are very dangerous, and non-structural cracks, which are less threatening as they occur in non-load bearing elements like walls. Cracks can be caused by factors like incorrect design/construction, overloading, moisture changes, thermal movement, creep, chemical reactions, and vegetation. Proper design, construction techniques, and maintenance can help control cracking.