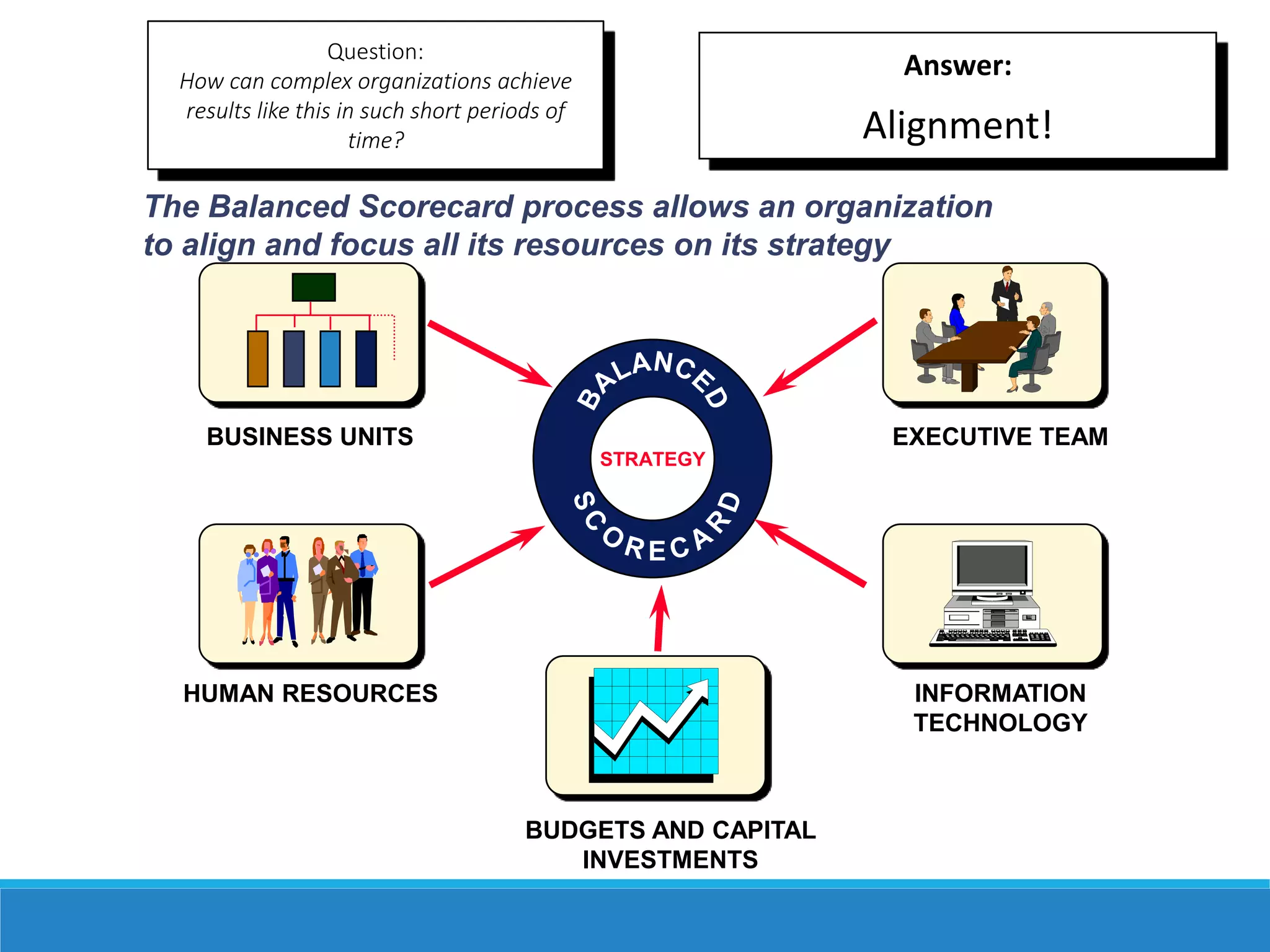

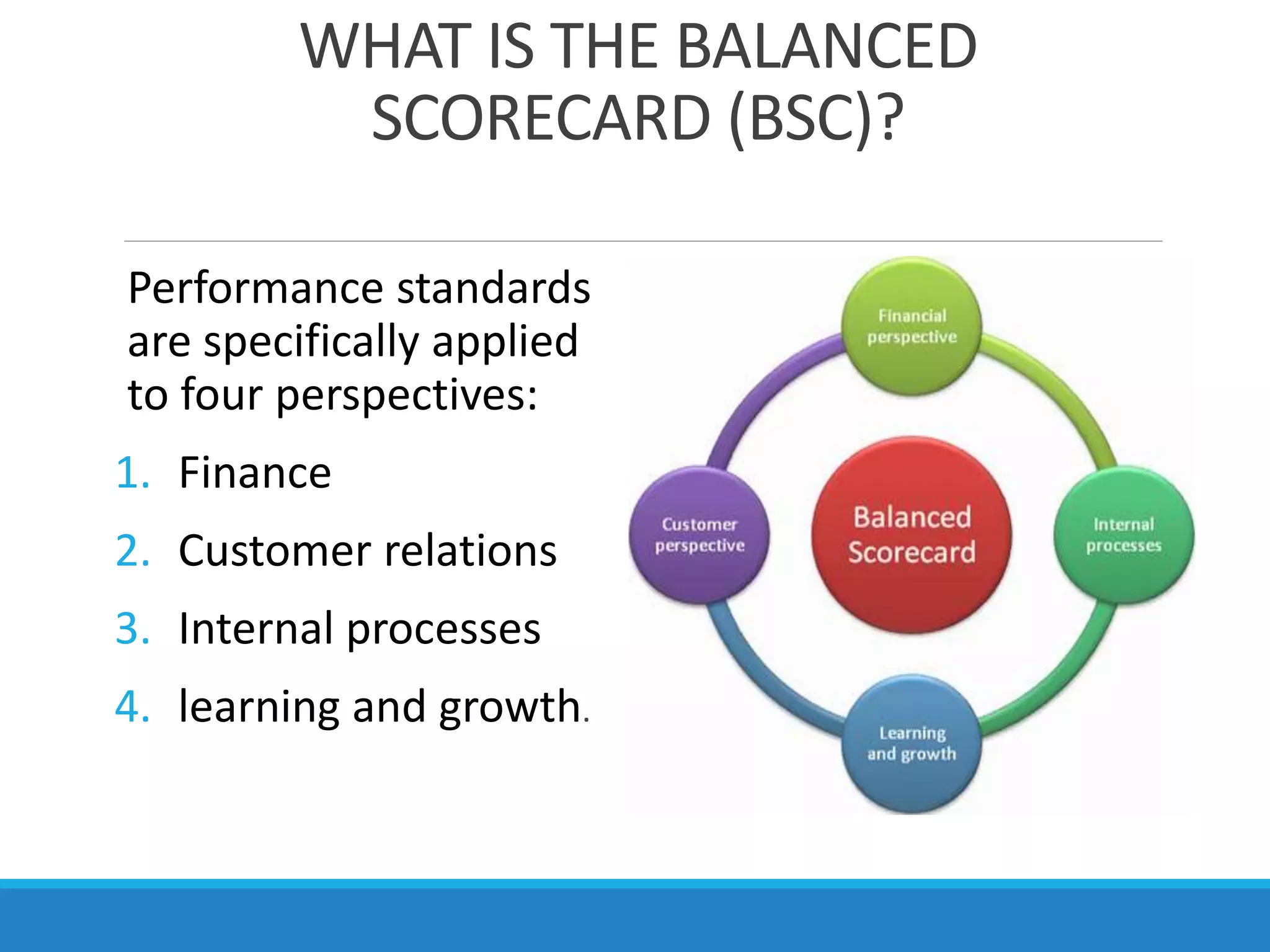

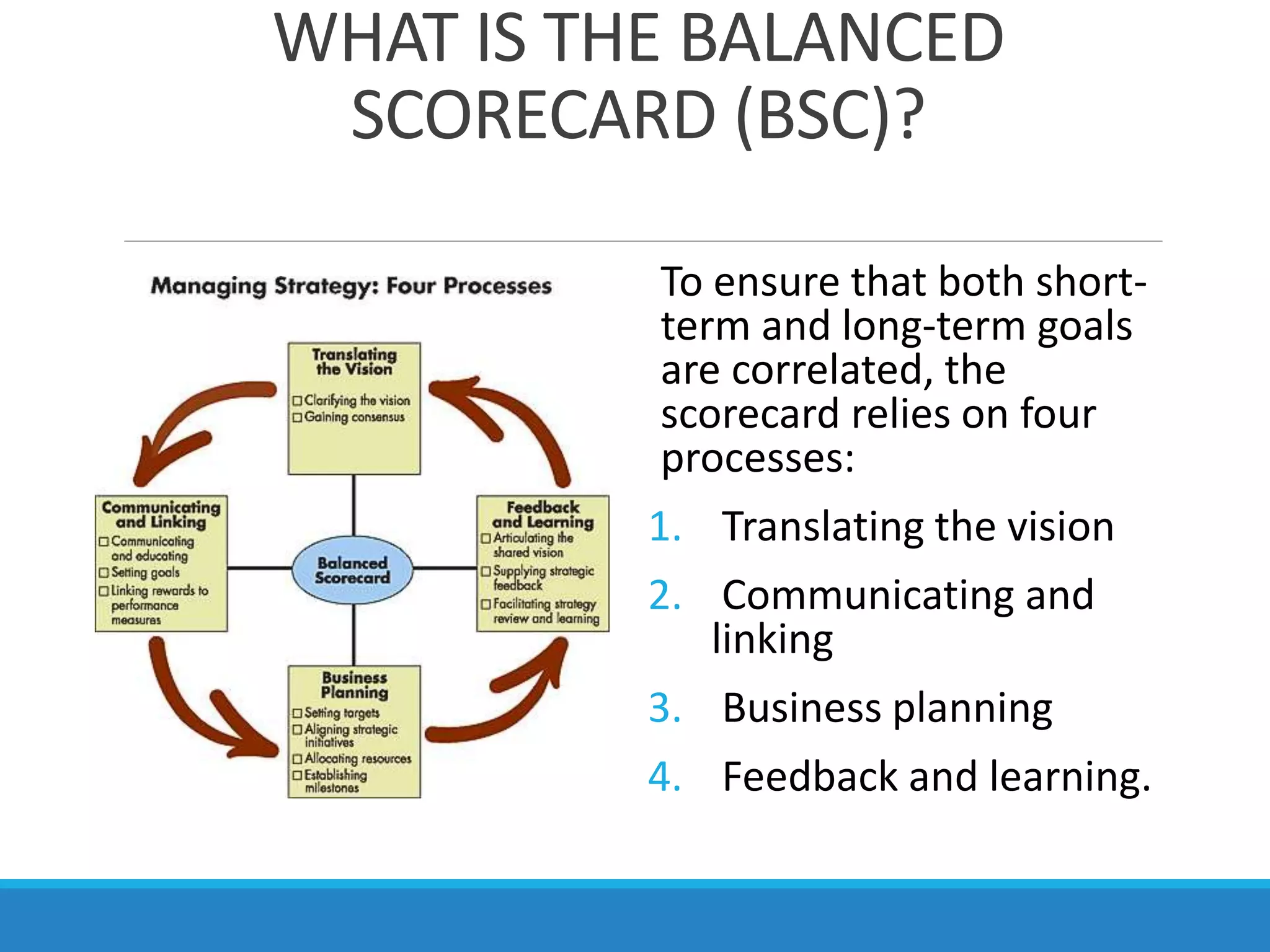

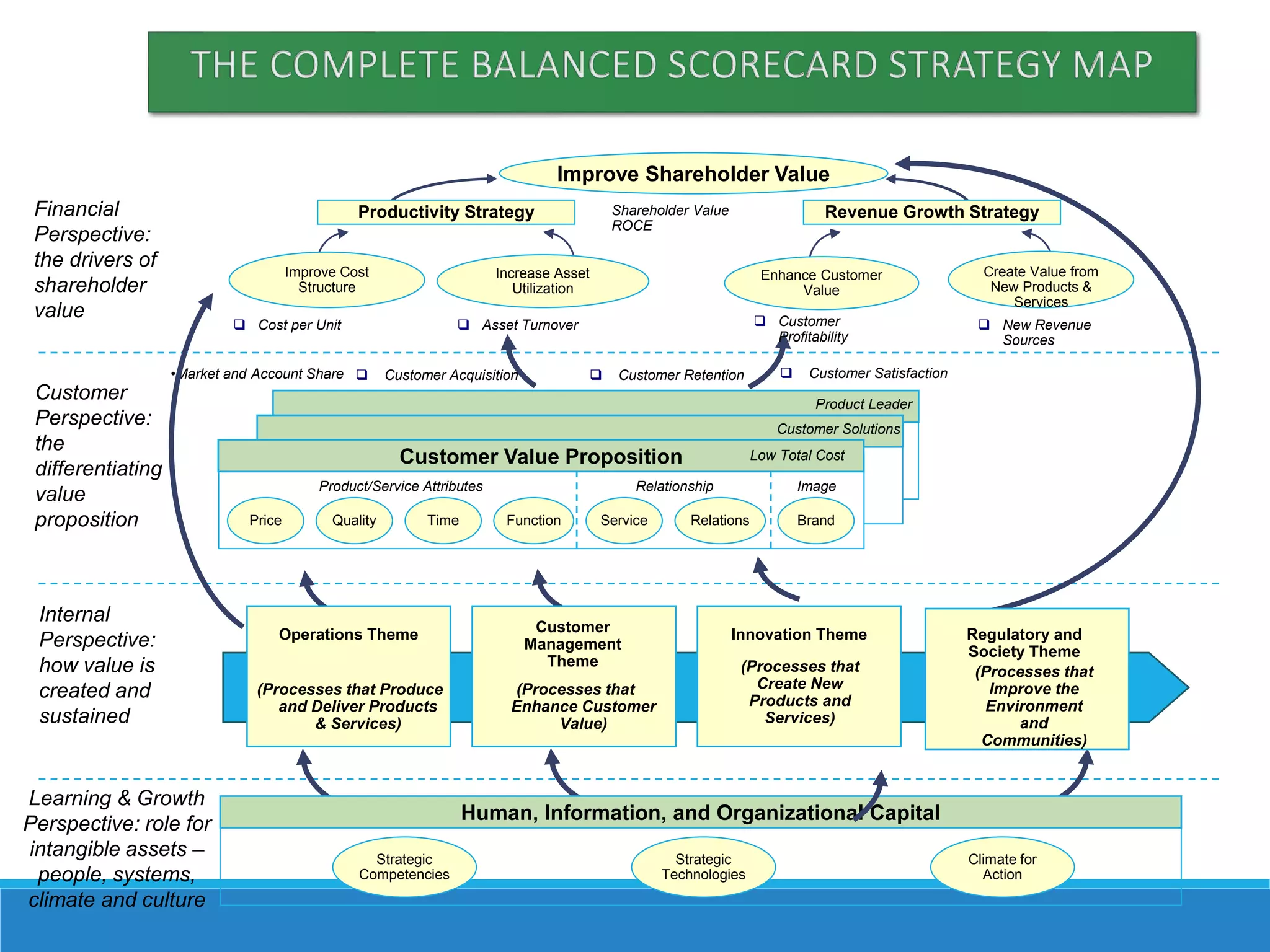

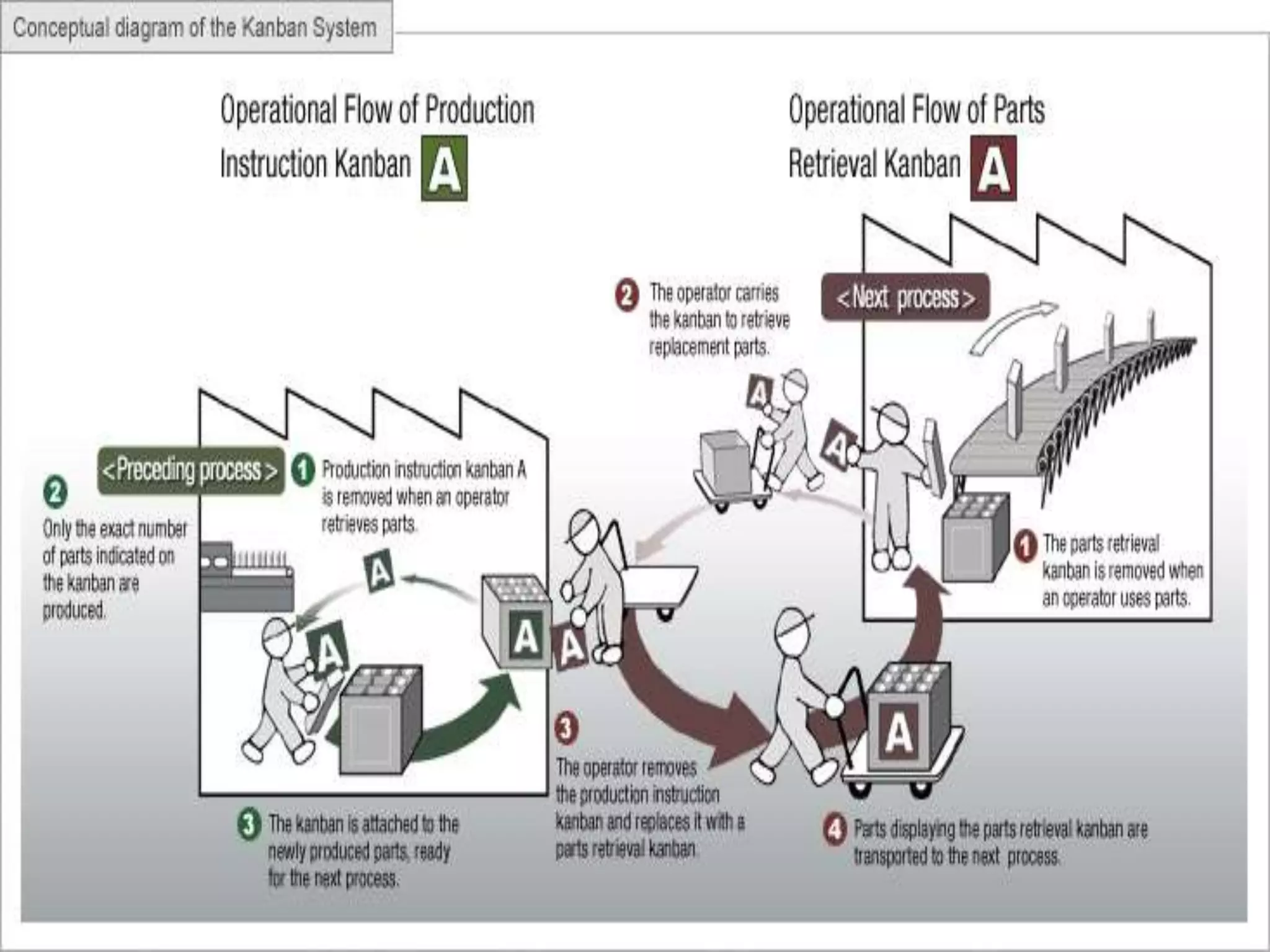

The document discusses the balanced scorecard and just-in-time manufacturing strategies. It defines the balanced scorecard as a strategic planning tool that measures performance across financial, customer, internal process, and learning/growth perspectives. It also explains how the balanced scorecard aligns strategic goals throughout an organization. Just-in-time aims to reduce waste from excess inventory by receiving materials just as they are needed in the production process. Popular examples where these strategies have been successfully implemented include Toyota, Dell, and Harley Davidson.