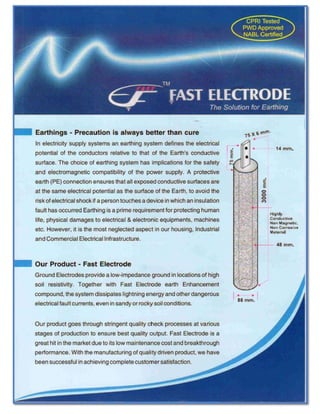

FAST ELECTRODE is a prominent manufacturer and supplier of maintenance free earthing electrodes made using latest technologies to ensure effective working. Their product undergoes stringent quality checks and is tested and certified by various government bodies. They offer a committed installation team and anticipate providing their eco-friendly and innovative earthing solutions for various industries.

![Tools and tackle

Sr.

Description

AT SITE

Drill machines [High Flash] 20mm.

Drill machines [M POWER] 20mm.

Multi meter.

Electric Breaker

Welding Machine

All type electrical Spanner & Tools

Earth testing meter

Meager

Zoola

AT FACTORY

Mechanical Press Machine

Radial Drill Machine

Welding Machine

Abrasive Cutter machine

Compressor

FOR INSPECTION

Micro Meter

Measuring Tape

Thickness Gauge

Vernier Caliber

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

Quantity

2 Nos

2 Nos

1 No

1 No

1 No

3 Set

2 Nos

1 No

1 No

1 No

1 No

1 No

1 No

1 No

1 No

2 Nos

1 No

1 No

Management Team

Sr.

1.

2.

3.

Name

Rahul Chakurkar

Mangesh Thakur

Milind Naik

Qualification

BE Electronics

BE Electrical

BE Metallurgy

Experience

6 Years

18 Years

20 Years

4.

5.

Vinayak Parshetti

Nilesh Patil

BE Electrical

ITI Electrician

4 Years

5 Years](https://image.slidesharecdn.com/fastelectrodeprofile-131218235618-phpapp01/85/Fast-electrode-profile-3-320.jpg)

![FAST ELECTRODE EARTHING & TERCEL LIGHTNING ARRESTOR

WORK EXECUTED:1. ALL INDIA RADIO, SINGHGAD

2. INDIAN INSTITUTE OF TROPICAL METOLOGY, MAHABALESHWAR

3. MAHARASHTRA STATE ELECTRICITY TRANSMISSION CO. LTD

4. MAHARASHTRA STATE ELECTRICITY DISTRIBUTION CO. LTD

5. FIAT INDIA AUTOMOTIVE LTD, CHAKAN

6. BAJAJ AUTO LTD, CHAKAN

7. GODREJ & BOYCE MFG. CO. LTD

8. DSK DEVELPOERS, PUNE

9. KUMAR PROPERTIES, PUNE.

10. SHIMUZU CORPORATION JAPAN [BRIGDSTONE, CHAKAN]

11. ORPAK SYSTEM LTD](https://image.slidesharecdn.com/fastelectrodeprofile-131218235618-phpapp01/85/Fast-electrode-profile-4-320.jpg)

![ON GOING PROJECT:-

1. NARMADA ENGINEERING [ Municipal Corporation of Greater Mumbai]

2. TEERTH DEVELOPERS,PUNE

3. MAHARASHTRA STATE ELECTRICITY DISTRIBUTION CO. LTD

4. SHREE SAIBABA SANSTHAN, SHIRDI

5. SHIMIZU CORPORATION

6. NATIONAL DEFENCE ACADEMY

7. COLLEGE OF MILITARY ENGINEERING

8. VASCON, PUNE.](https://image.slidesharecdn.com/fastelectrodeprofile-131218235618-phpapp01/85/Fast-electrode-profile-5-320.jpg)