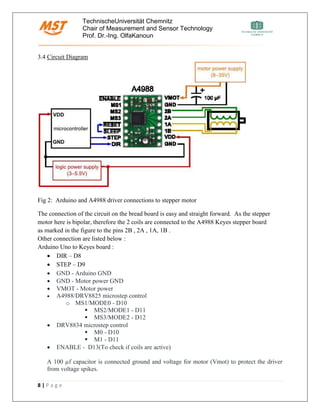

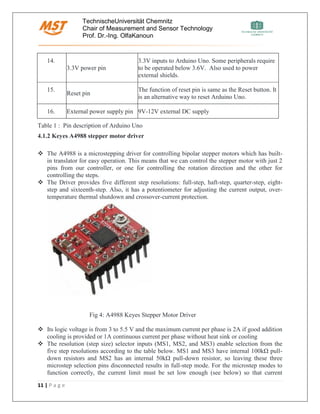

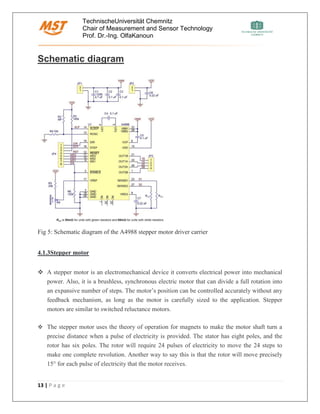

The document details a project at Technische Universität Chemnitz focused on controlling and optimizing a 3D optical stage for precise movement using stepper motors and Arduino Uno. It includes an abstract, project description, member responsibilities, specifications of components, implementation details, and references, highlighting the importance of stepper motors in industrial automation and robotics for precise positioning. The project demonstrates the integration of software and hardware to achieve controlled movement through a user-friendly interface.

![TechnischeUniversität Chemnitz

Chair of Measurement and Sensor Technology

Prof. Dr.-Ing. OlfaKanoun

25 | P a g e

8. References

• [1]" A4988 Driver and Arduino ", Itead.cc, 2017. [Online]. Available:

https://github.com/laurb9/StepperDriver. [Accessed: 2- Jun- 2017].

• [2]" How to use A4988 to control stepper motor ", Itead.cc, 2017. [Online]. Available:

http://howtomechatronics.com/tutorials/arduino/how-to-control-stepper-motor-with-a4988-

driver-and-arduino/. [Accessed: 27- May- 2017]

• [3]" A4988 Specification and purchase ", Itead.cc, 2017. [Online]. Available:

https://www.pololu.com/product/1182 [Accessed: 21- Jun- 2017]

• [4]" Bipolar and Unipolar Stepper Motor", Itead.cc, 2017. [Online]. Available:

https://www.circuitspecialists.com/blog/unipolar-stepper-motor-vs-bipolar-stepper-motors/

[Accessed: 5- May- 2017]

• [5]" TeraTerm ", Itead.cc, 2017. [Online]. Available:

https://learn.sparkfun.com/tutorials/terminal-basics/tera-term-windows [Accessed: 20- Jun-

2017]

• [6]" Stepper motor using arduino ", Itead.cc, 2017. [Online]. Available:

http://www.instructables.com/id/Drive-a-Stepper-Motor-with-an-Arduino-and-a-A4988-/

[Accessed: 20- Apr- 2017]

• [7]" Arduino pin out ", Itead.cc, 2017. [Online]. Available:

http://www.electroschematics.com/7958/arduino-uno-pinout/ [Accessed: 13- Apr- 2017]](https://image.slidesharecdn.com/controllingandoptimizationof3dopticalstageforprecisegroup13-170829075430/85/Controlling-and-optimization-of-3d-optical-stage-for-precise-movement-25-320.jpg)