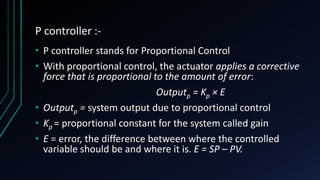

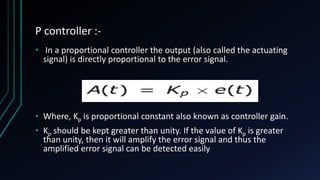

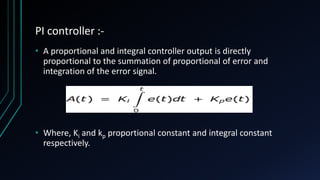

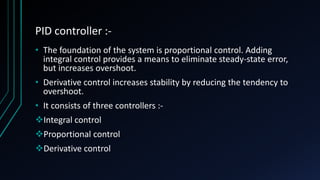

This document discusses P, PI, and PID controllers. P controllers use proportional control to reduce error, but can still have steady state error. PI controllers add integral control to eliminate steady state error, at the cost of increased overshoot. PID controllers further add derivative control to increase stability by reducing overshoot. The output of a PID controller is the sum of proportional, integral, and derivative responses to the error between the measured and desired set point values.