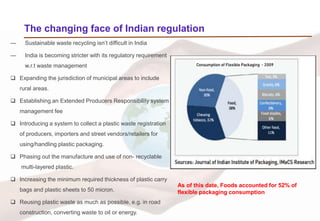

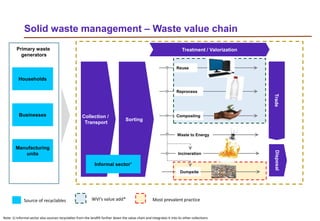

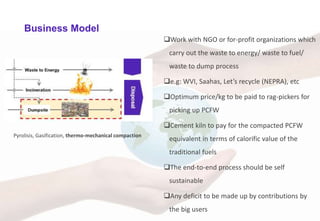

This document discusses sustainable packaging in India and proposes a solution to manage flexible plastic packaging waste. It notes that flexible plastic packaging makes up a large portion of packaging waste in India that is not recycled. The proposal is to establish a system where companies offset the amount of flexible plastic packaging they produce by ensuring an equivalent weight is collected and sent to cement kilns to be used as an alternative fuel. Cement kilns can fully combust this waste while generating energy and ash that can be used in cement production. This approach would create a market for flexible plastic waste, incentivize its collection, and generate environmental and economic benefits for India.