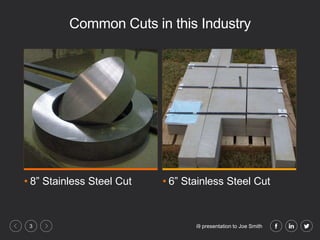

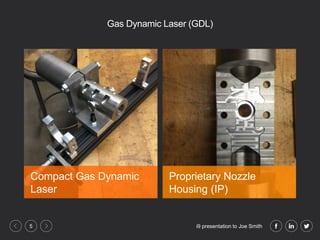

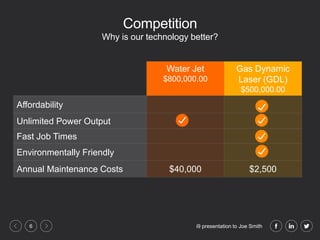

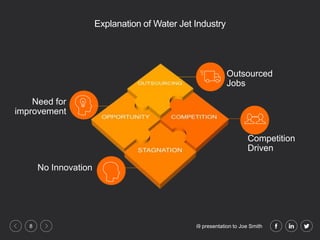

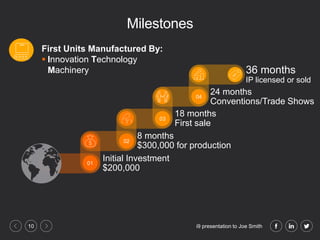

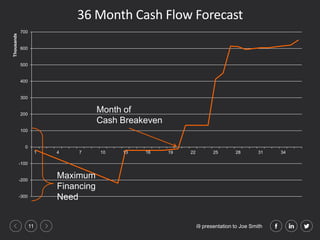

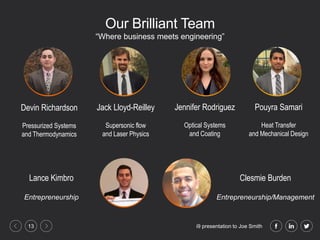

The presentation proposes a new gas dynamic laser (GDL) technology for cutting various materials such as stainless steel. The GDL would provide an affordable and environmentally friendly alternative to existing water jet and CO2 laser technologies. It would offer unlimited power output, fast job times, and lower annual maintenance costs compared to water jets. The presentation outlines an initial $200,000 investment plan over 3 years to develop and commercialize the GDL technology through direct sales, licensing the intellectual property, attending trade conventions, and building a sales force.