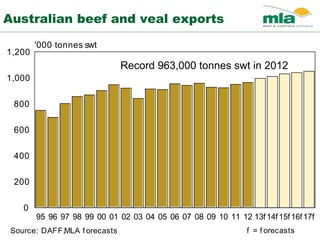

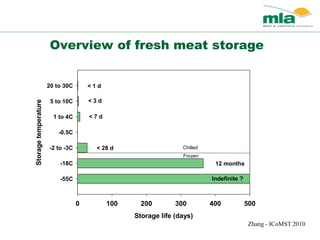

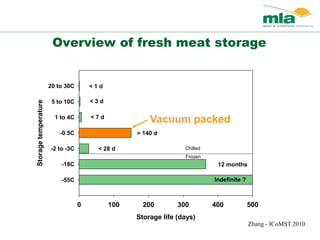

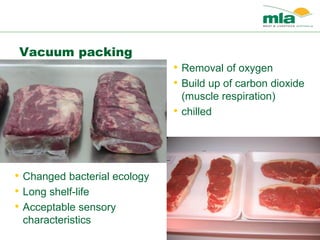

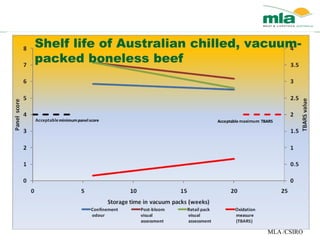

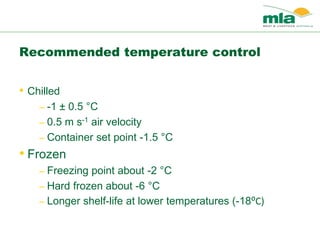

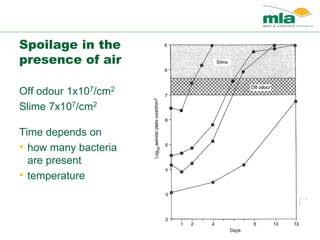

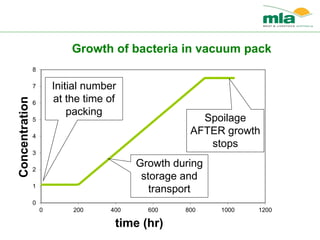

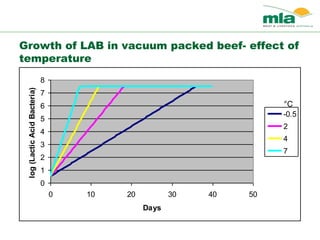

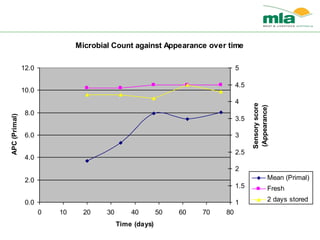

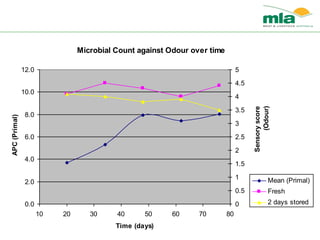

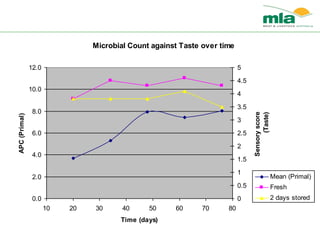

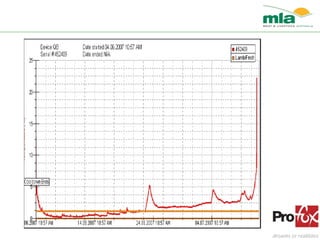

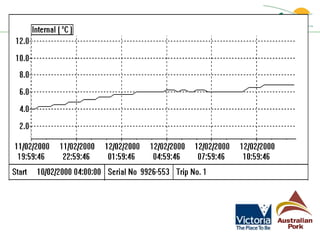

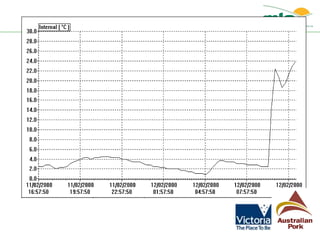

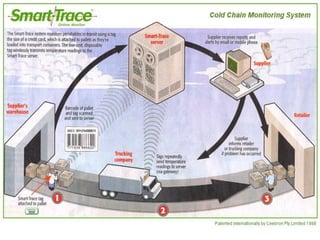

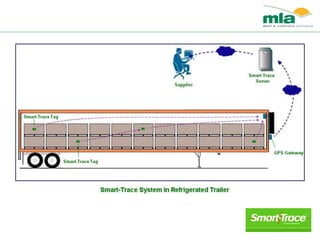

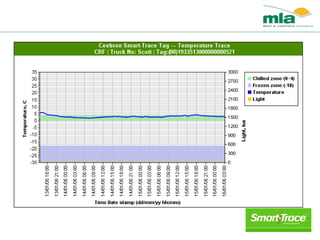

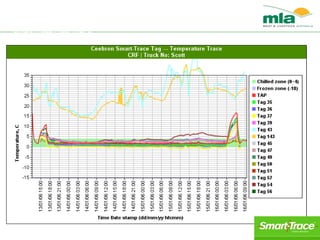

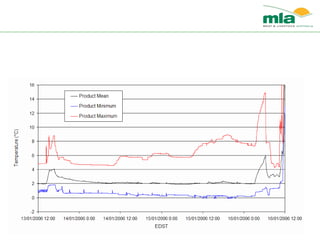

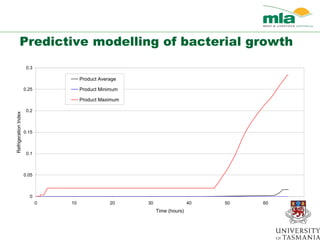

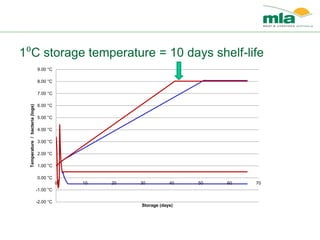

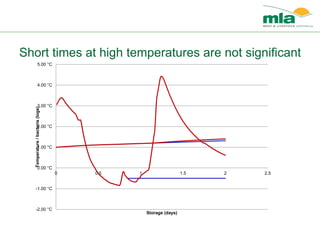

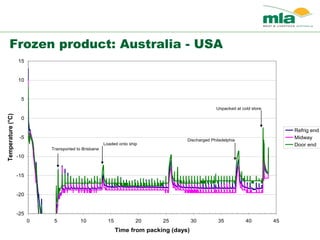

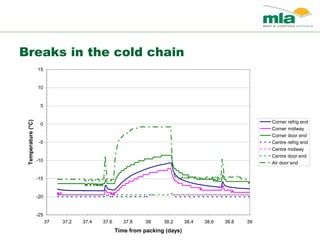

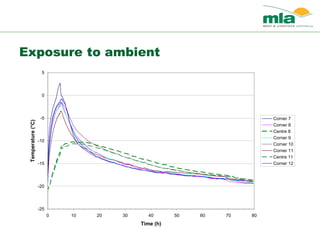

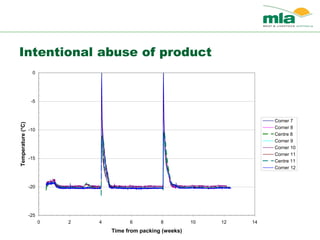

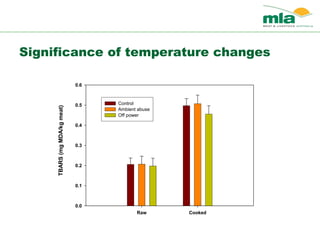

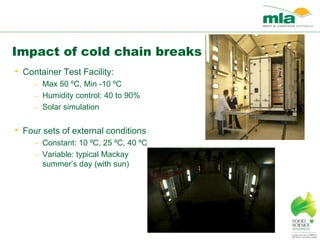

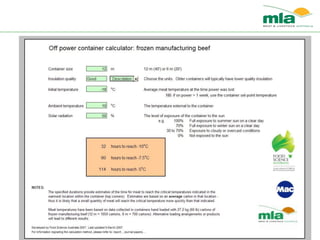

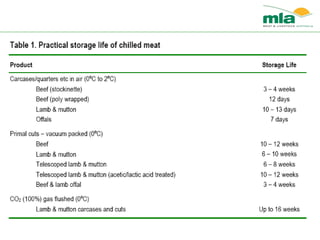

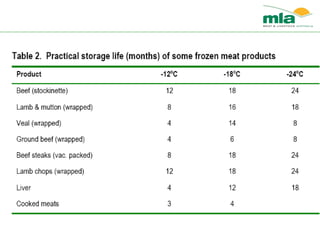

The document discusses the importance of cold chain management for maintaining the safety and suitability of fresh meat products during international trade, emphasizing the definition of fresh meat and factors affecting shelf-life such as temperature and monitoring. It highlights various case studies and consumer perceptions while detailing how improper temperature management can lead to spoilage and safety issues. Additionally, it covers insights into the shelf-life of different meat types and innovative technology for real-time temperature monitoring in the supply chain.