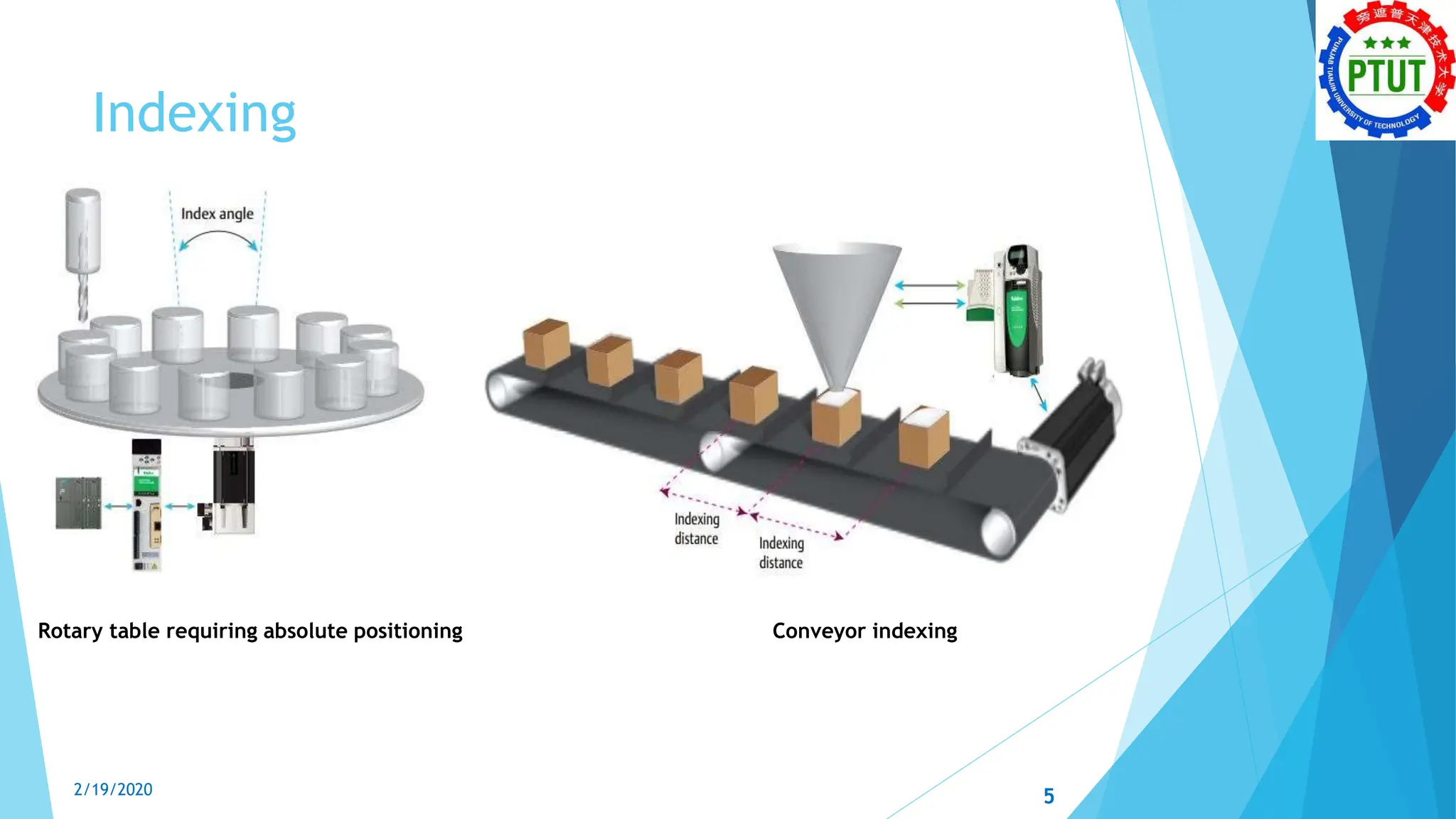

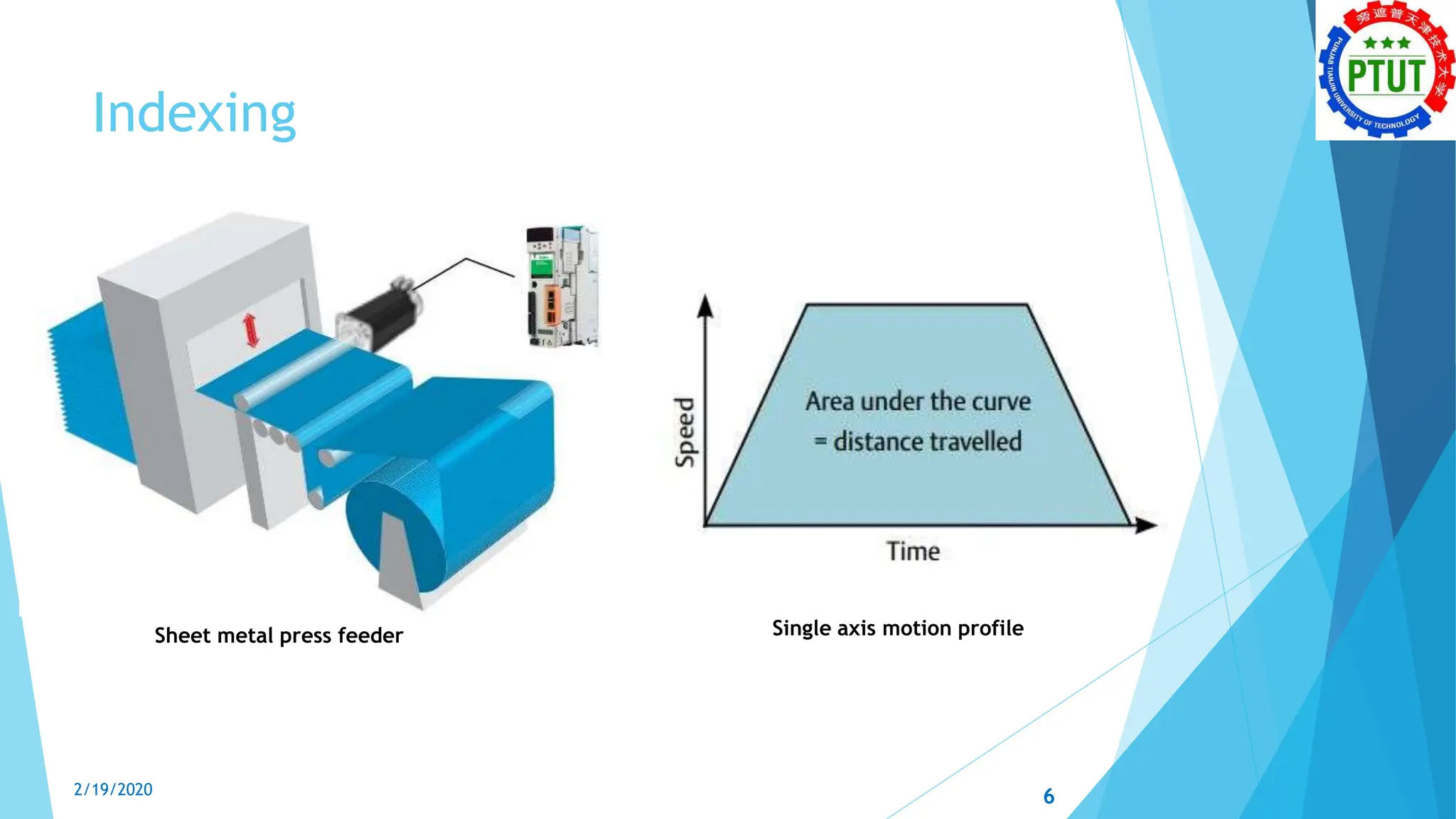

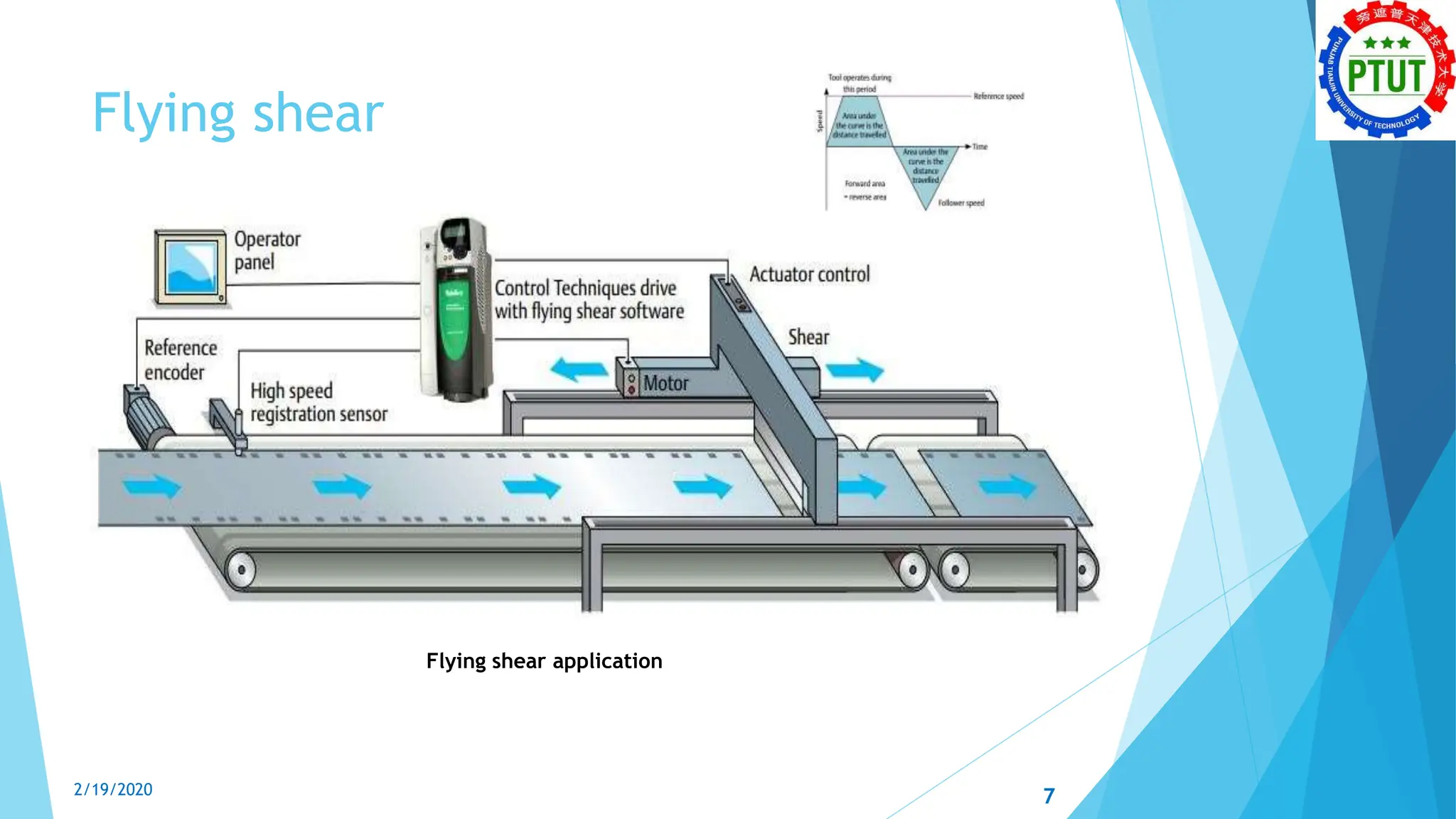

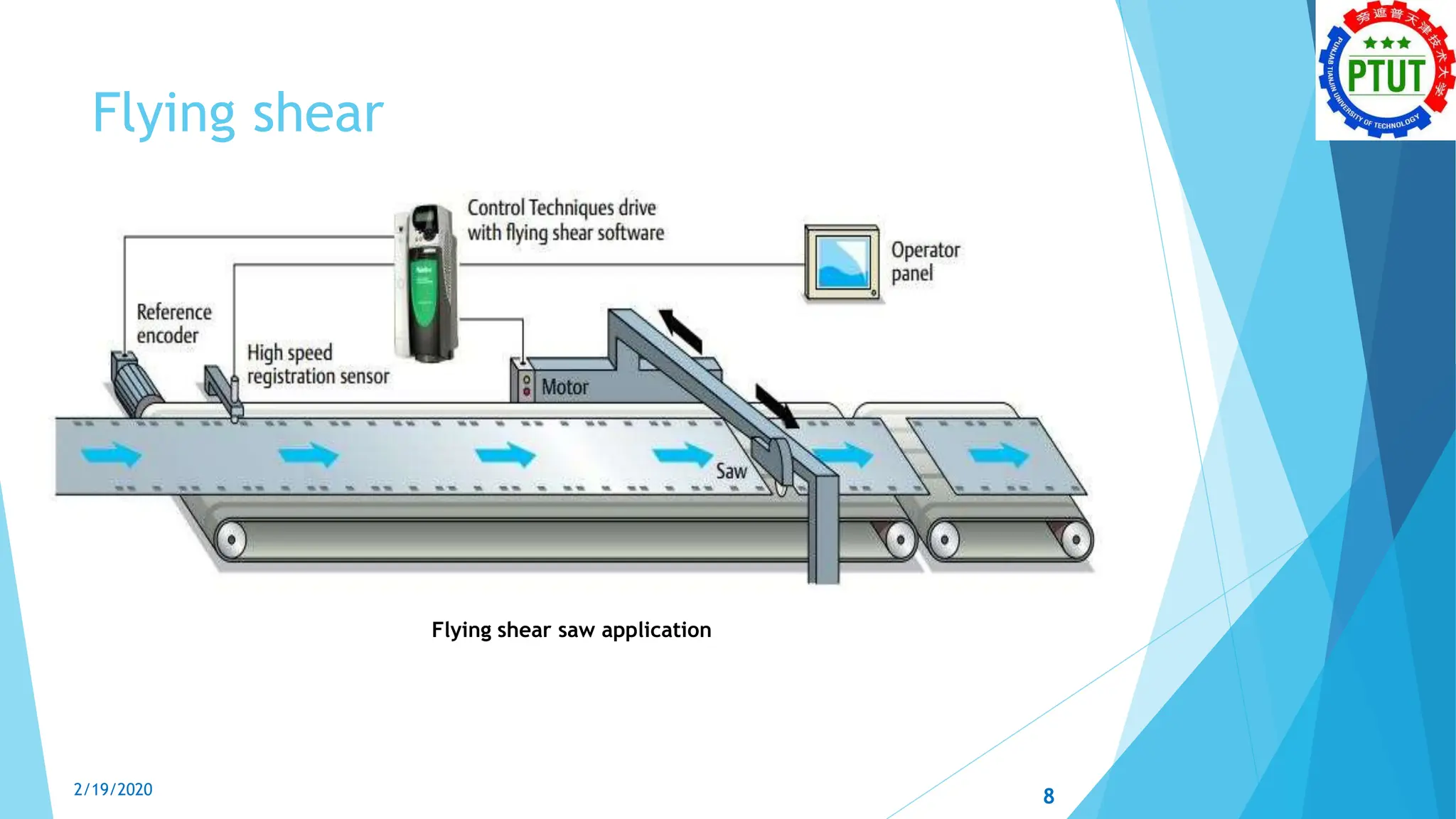

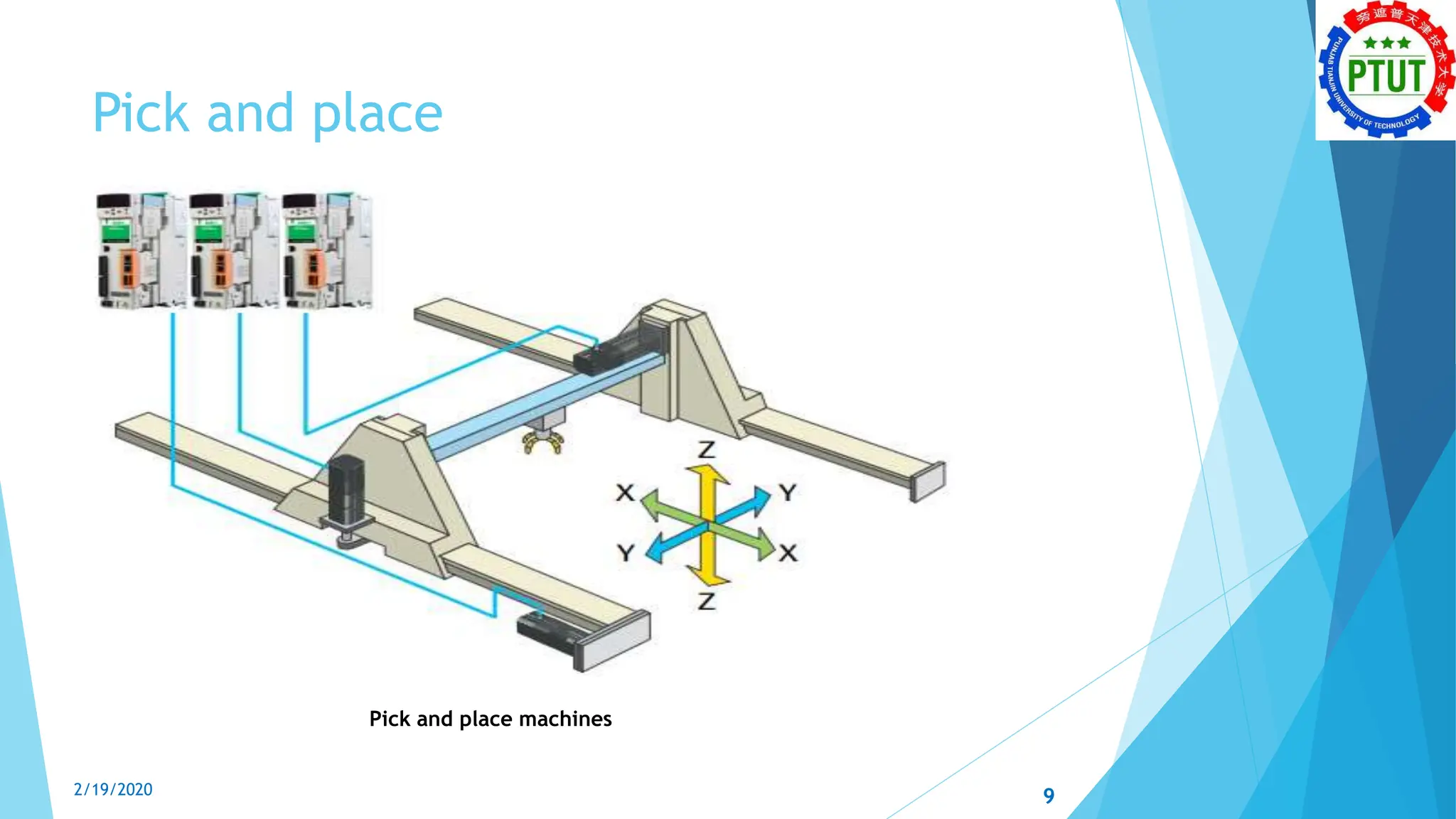

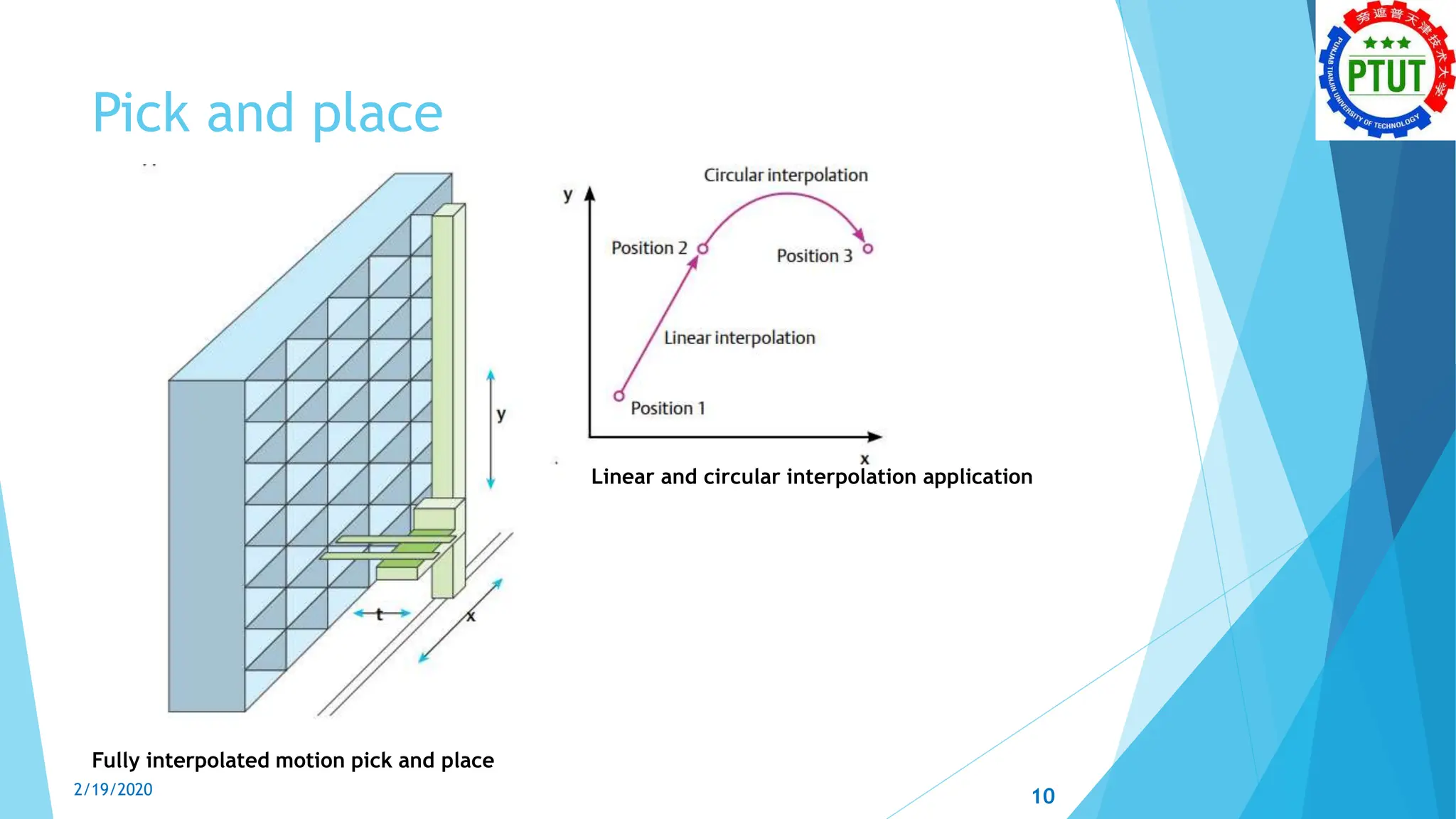

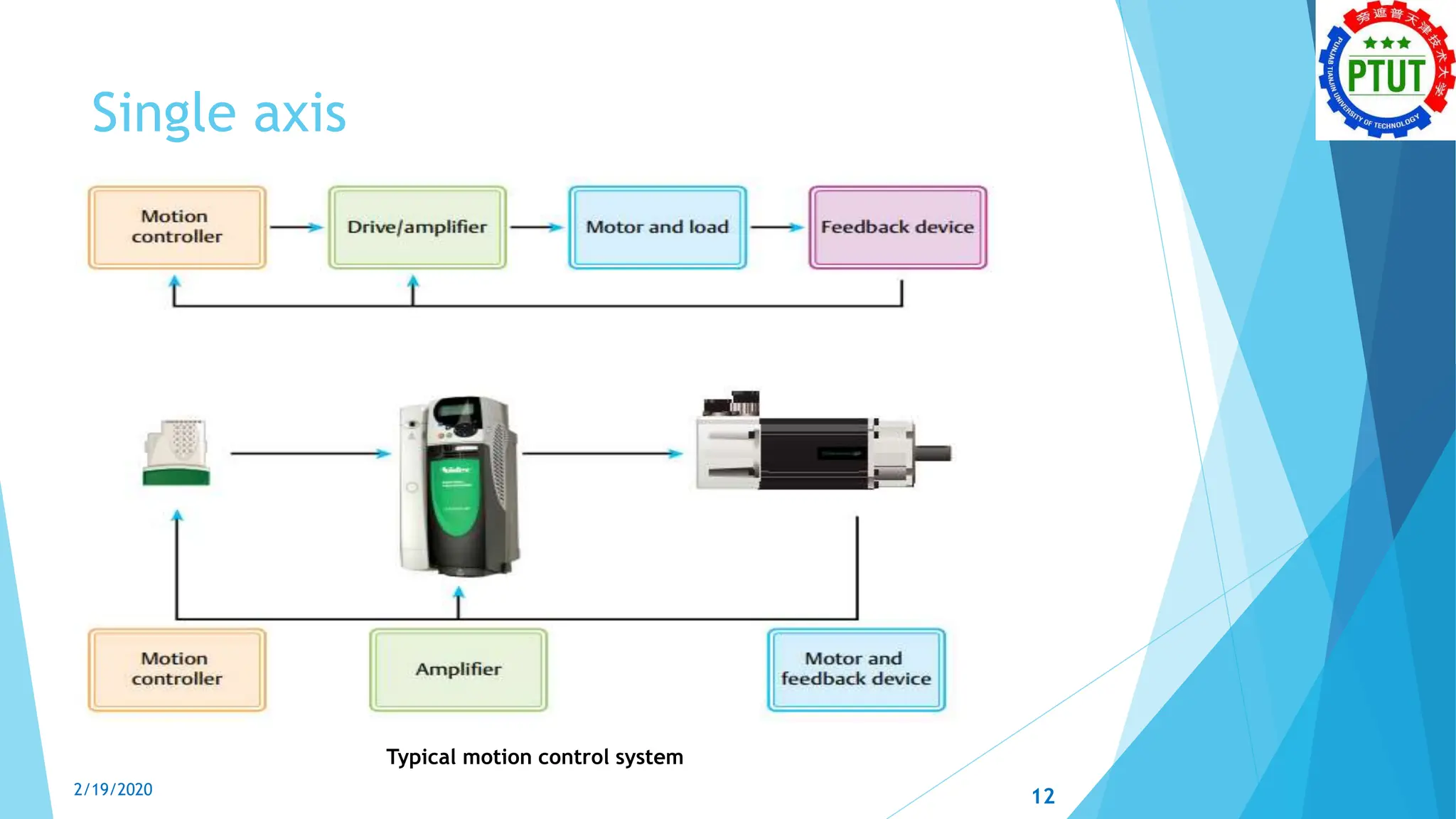

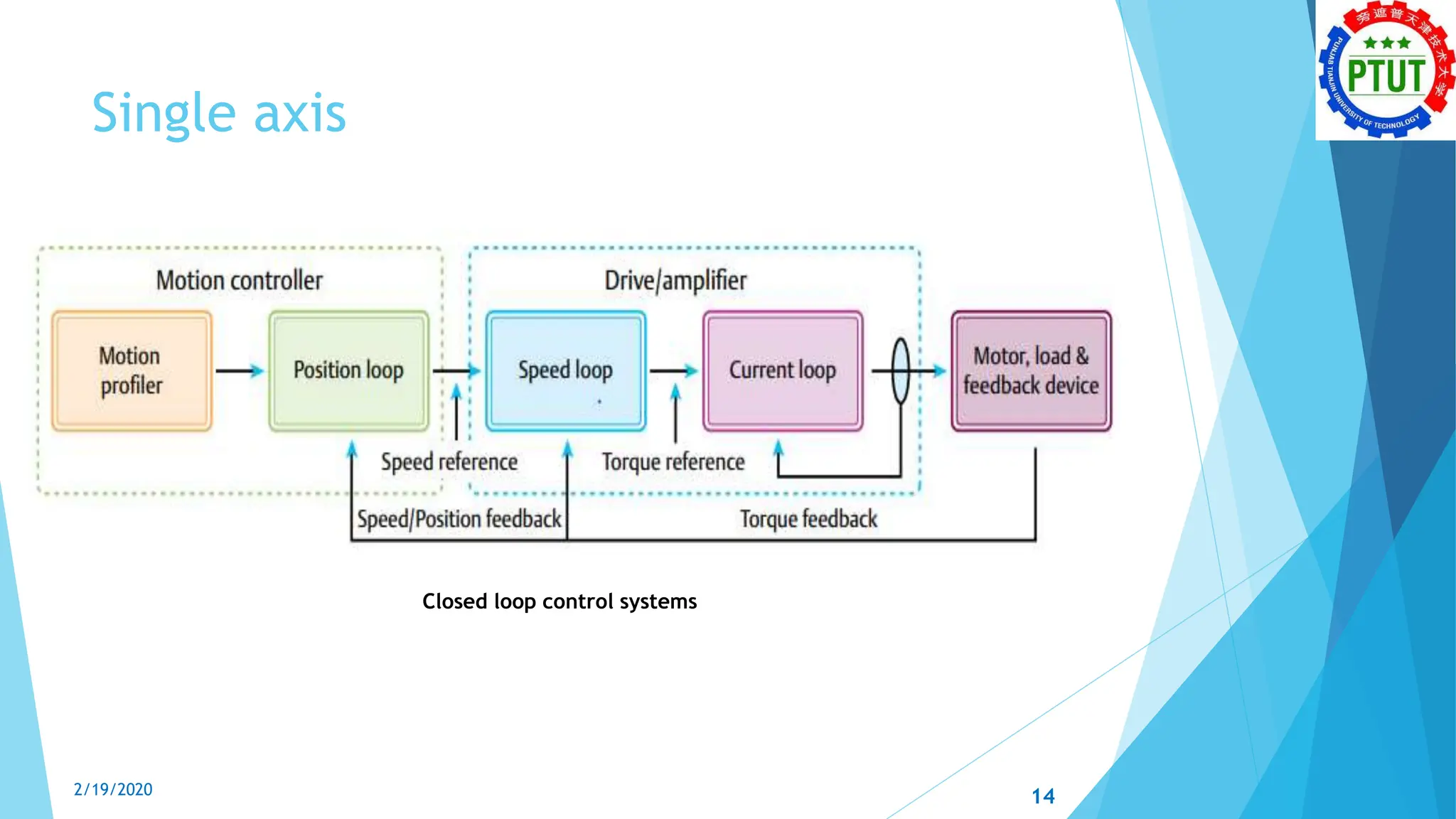

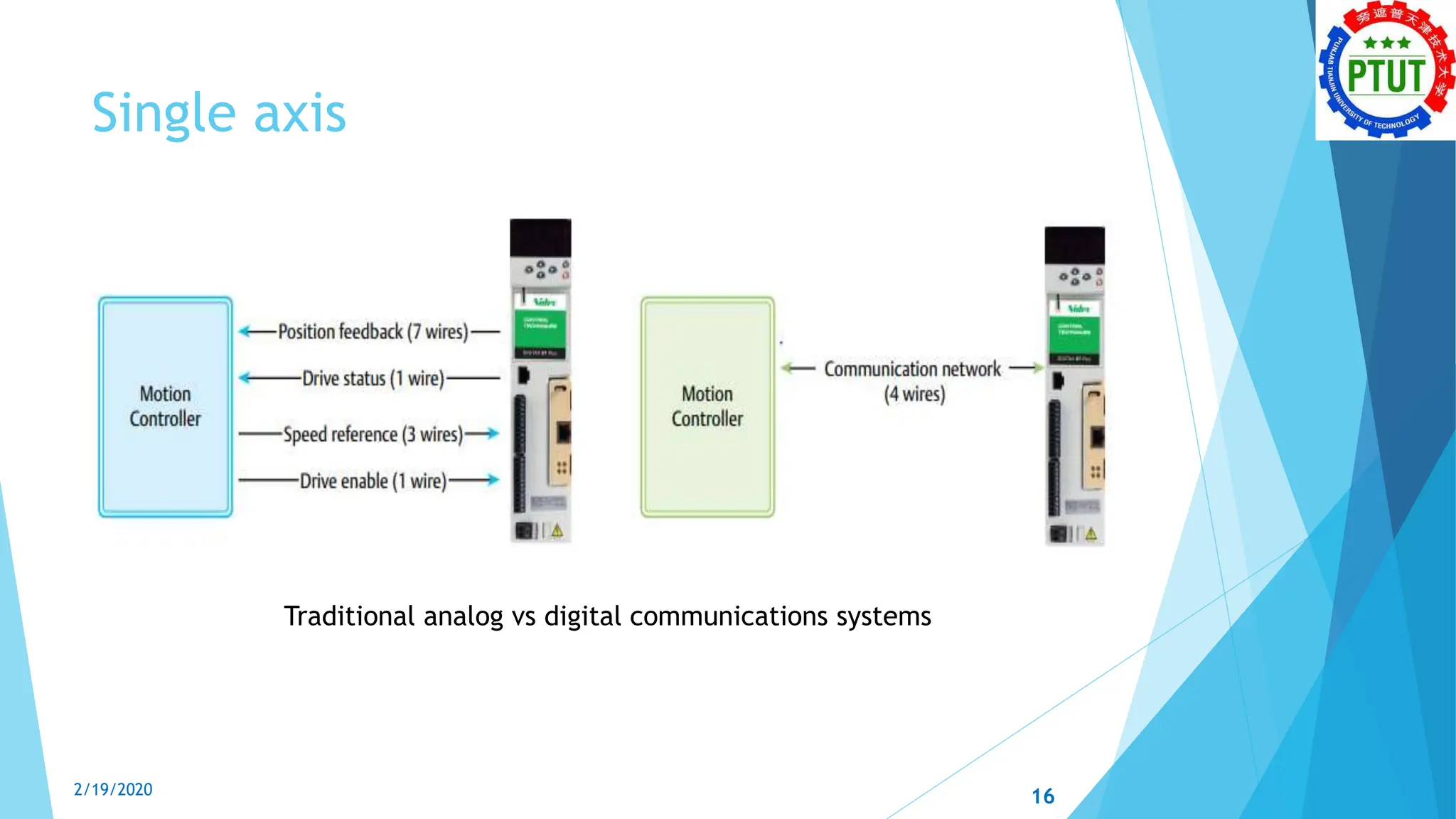

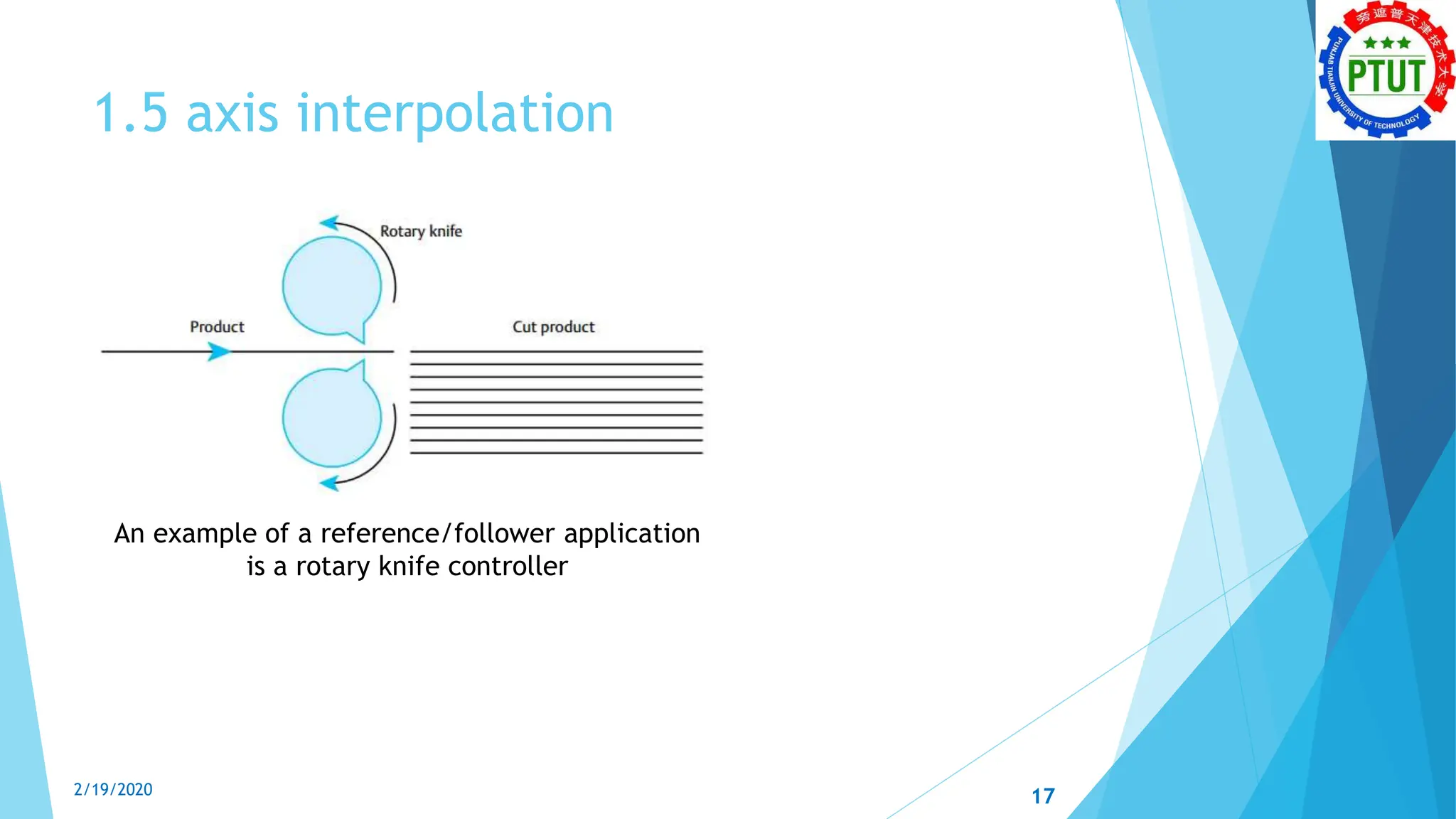

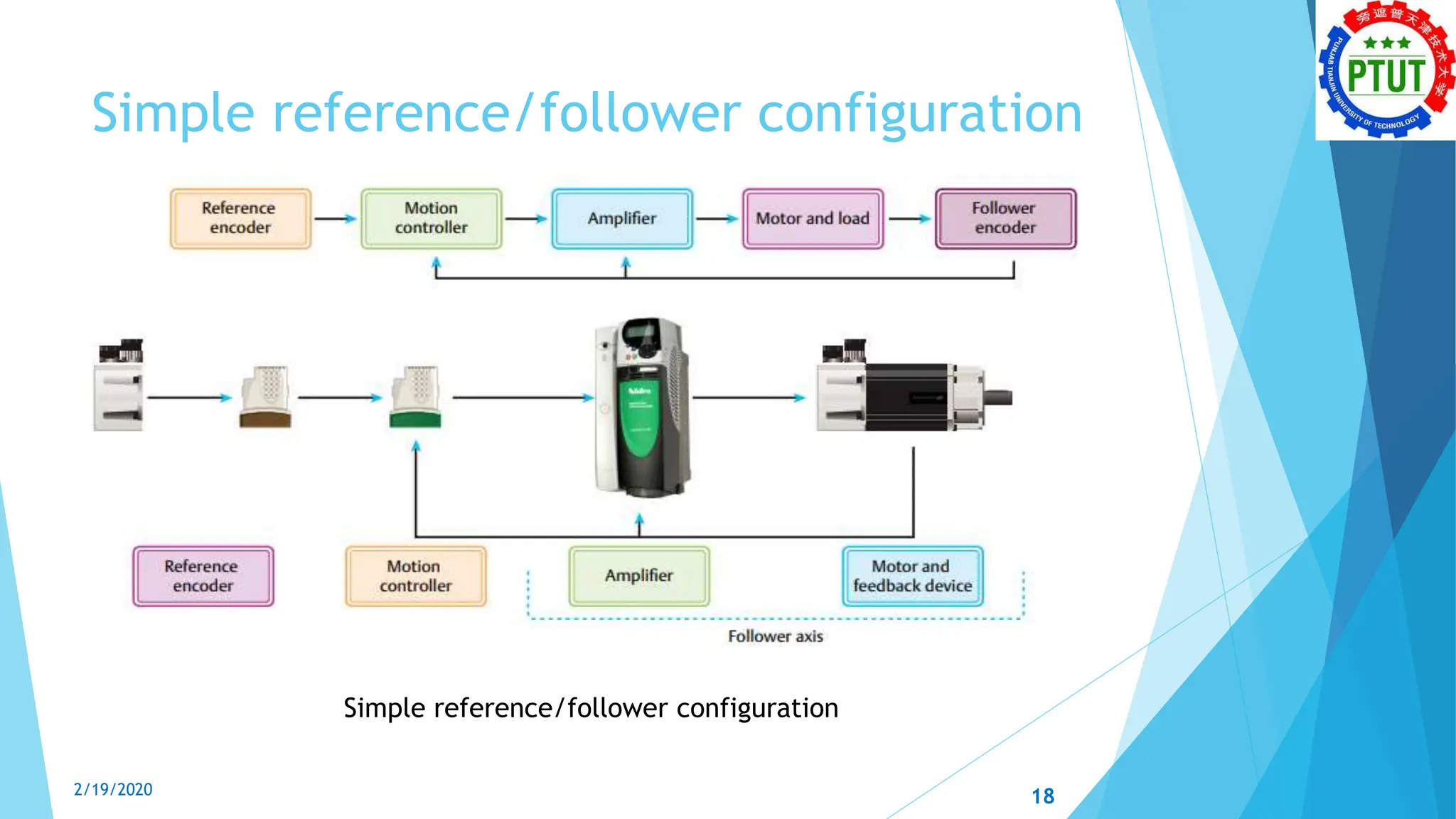

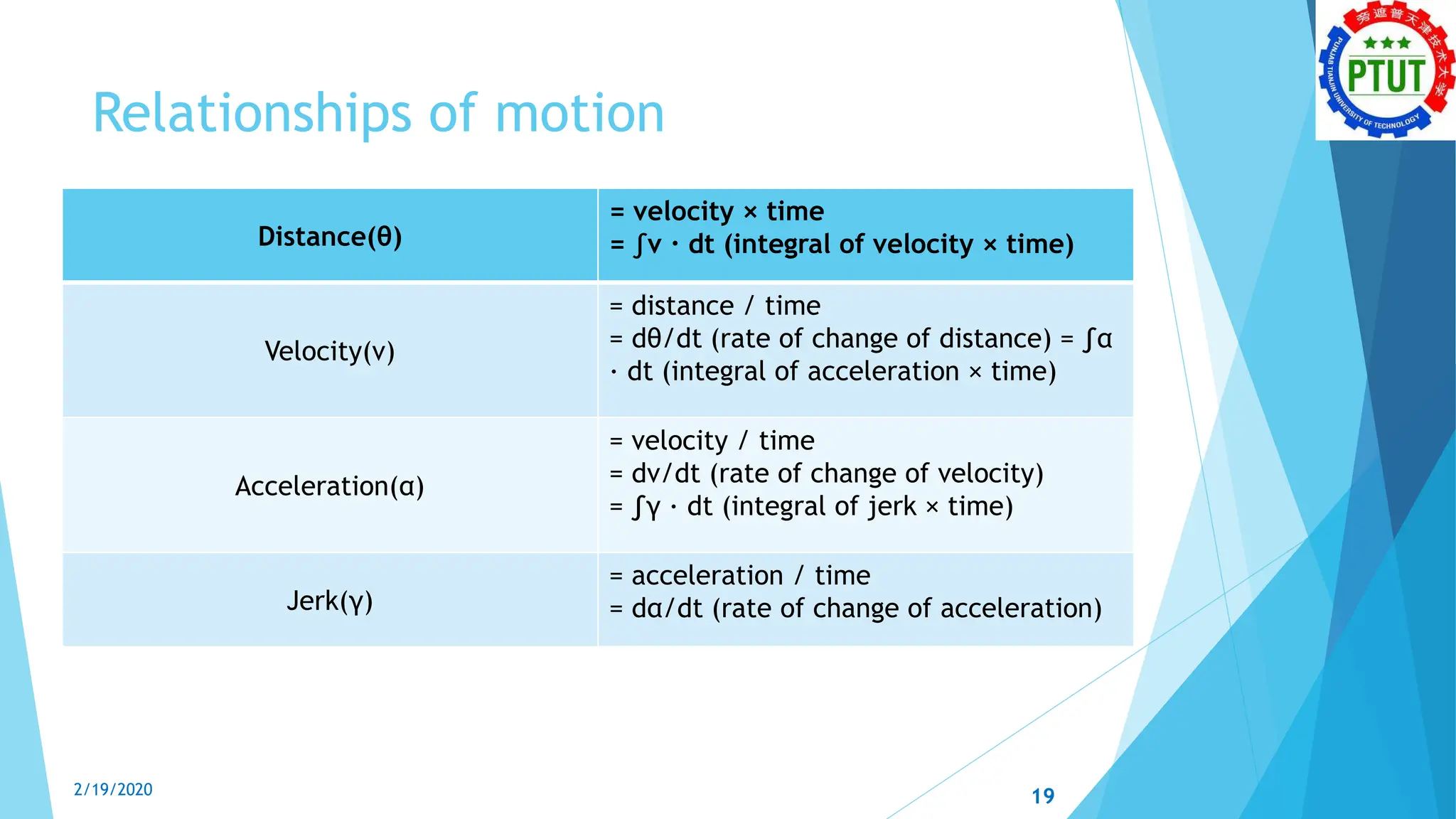

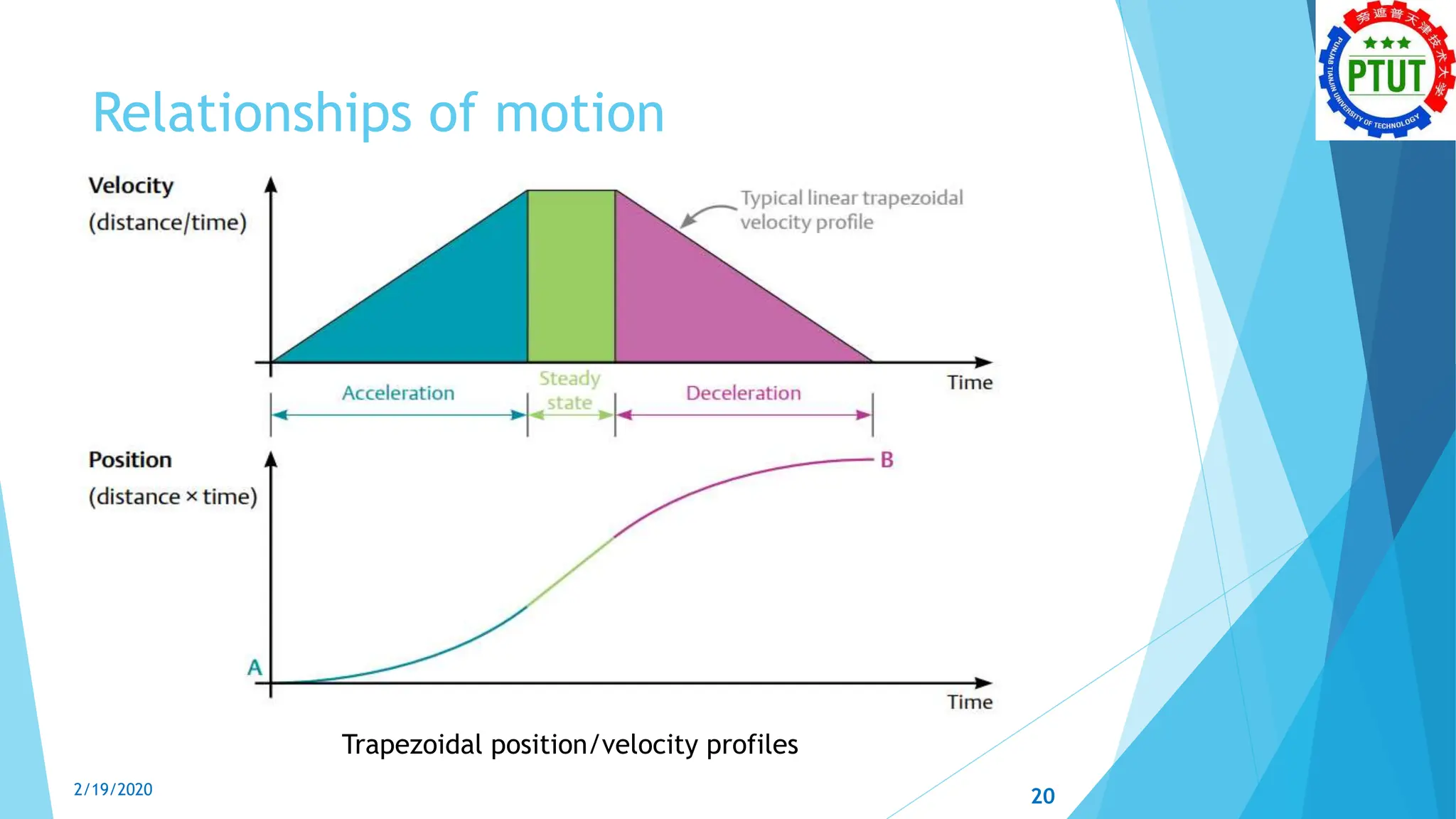

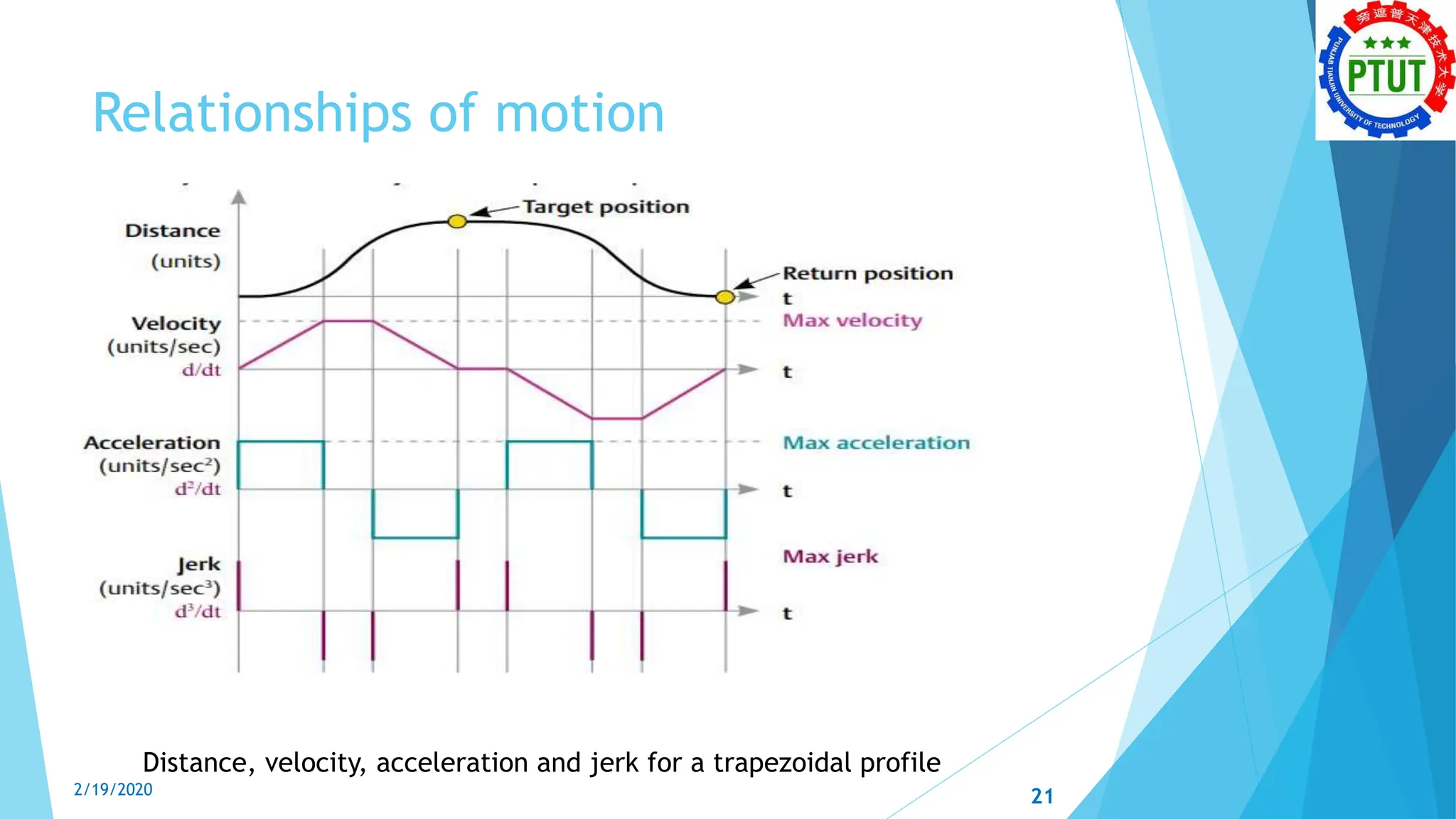

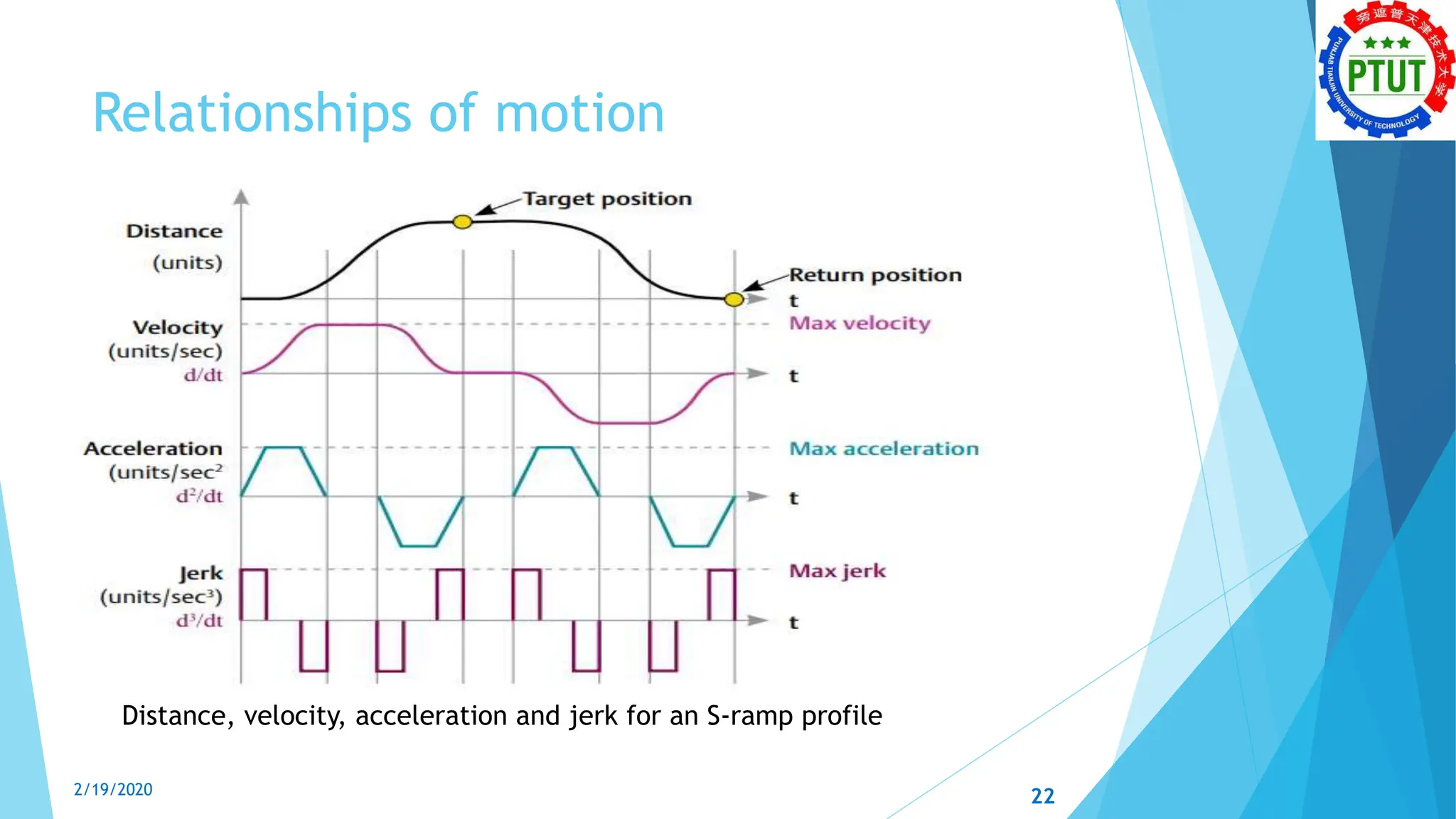

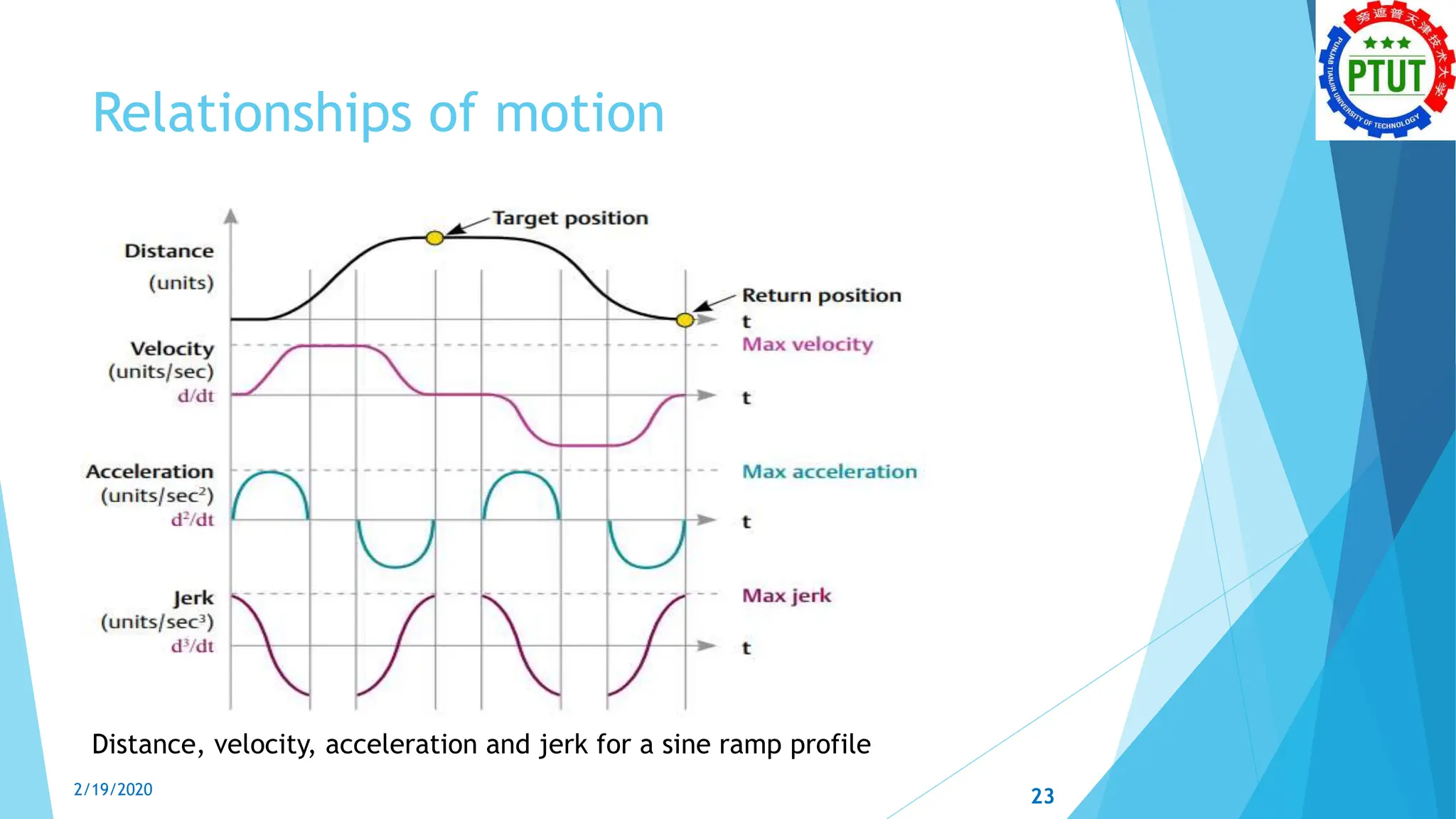

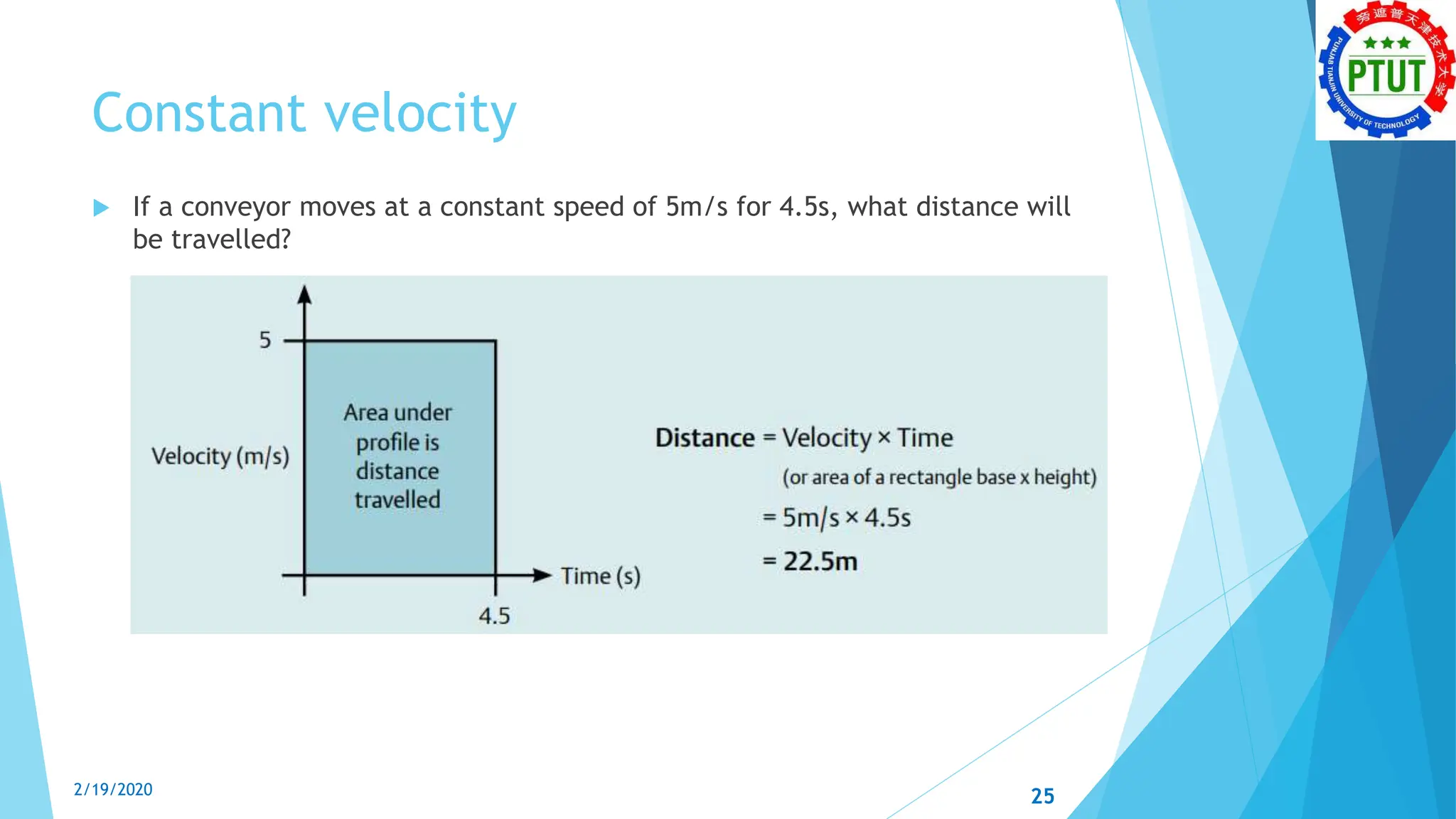

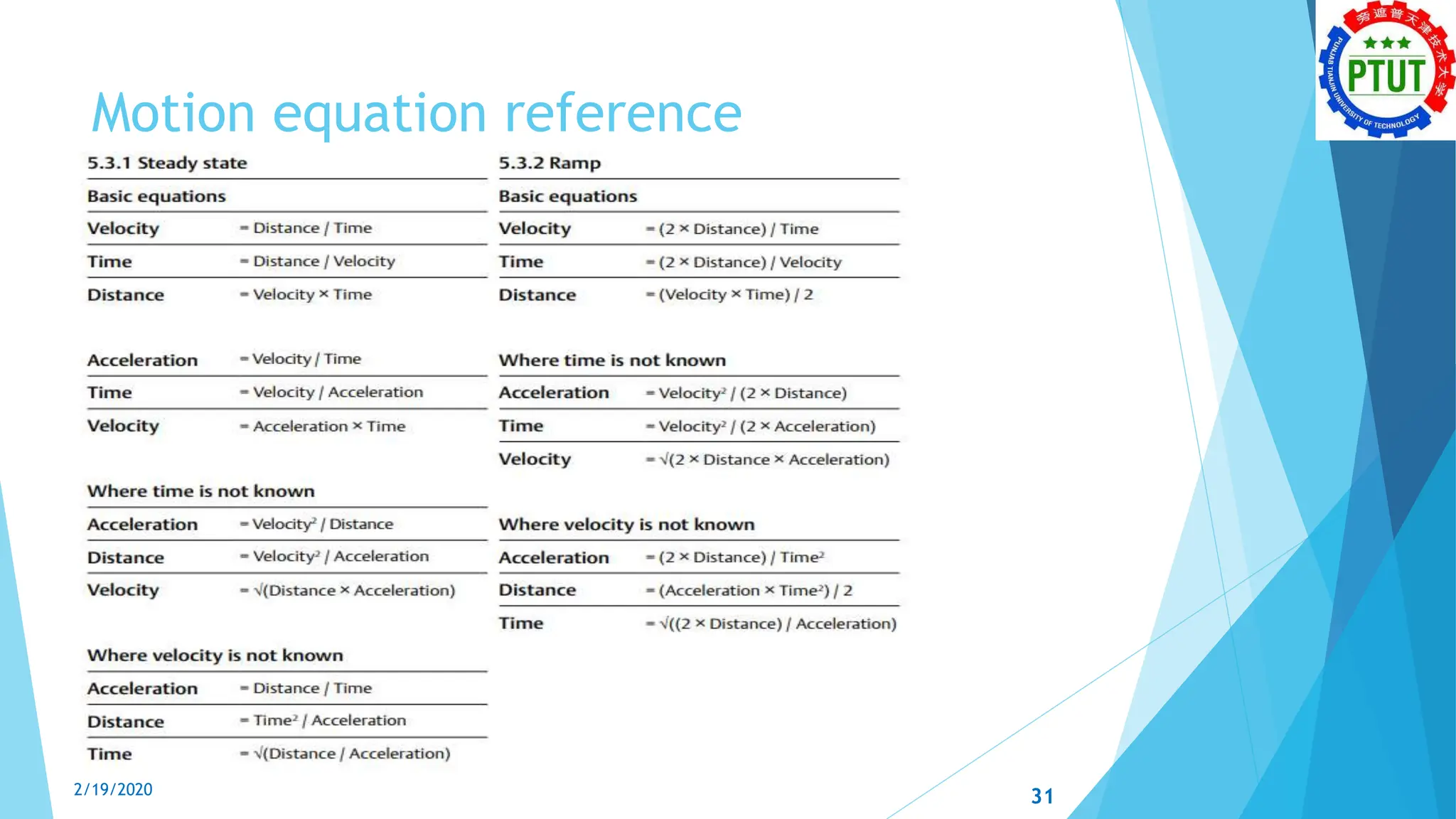

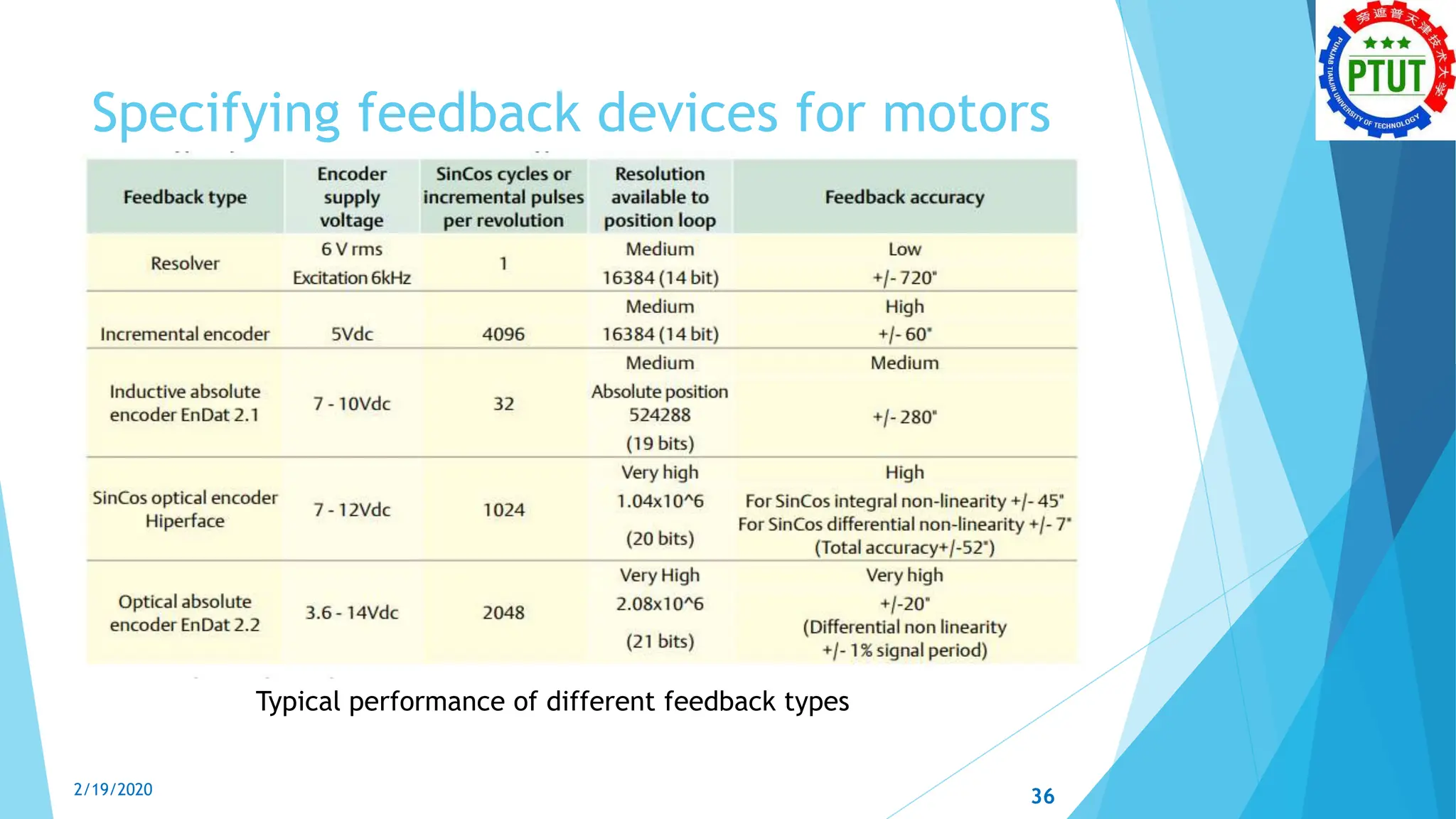

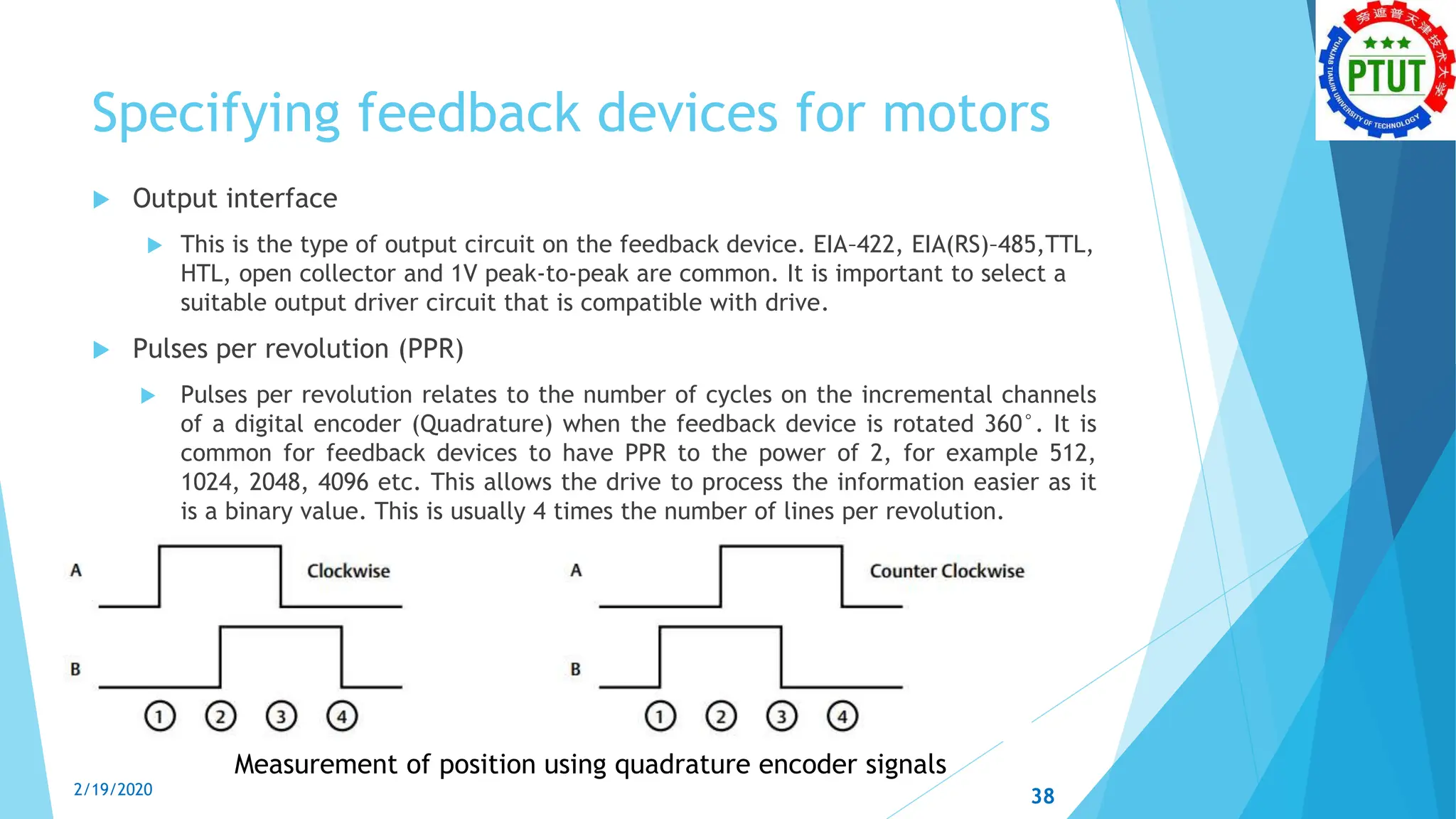

This document provides an overview of motion control technologies and concepts. It discusses common industrial motion applications like indexing, flying shears, and pick and place machines. It also covers motion system layouts, relationships of motion using equations, specifying feedback devices for motors, and examples of single and 1.5 axis interpolation motion profiles. Feedback device characteristics like accuracy, resolution, pulses/revolutions are explained.