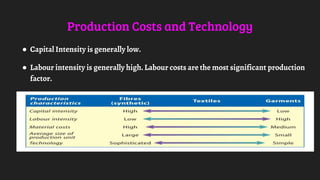

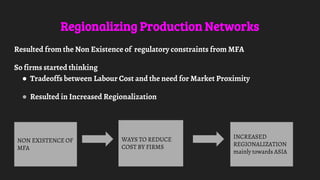

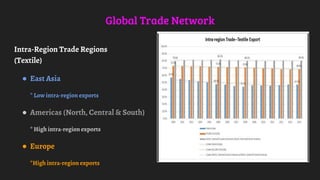

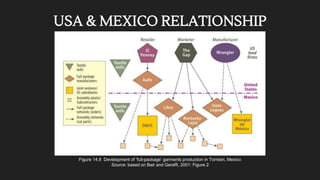

The clothing industry has undergone major global shifts since the phase out of the Multi-Fibre Arrangement (MFA) in 2005. Large apparel firms and retailers have moved production to regions with lower labor costs, especially Asia. China is now the world's largest clothing exporter, employing over 10 million workers, while Bangladesh exports over $25 billion annually, largely to Europe and North America. Regional trade blocs like NAFTA have integrated textile and apparel production networks within regions. Labor conditions and environmental sustainability remain ongoing issues as the industry continues to regionalize globally.