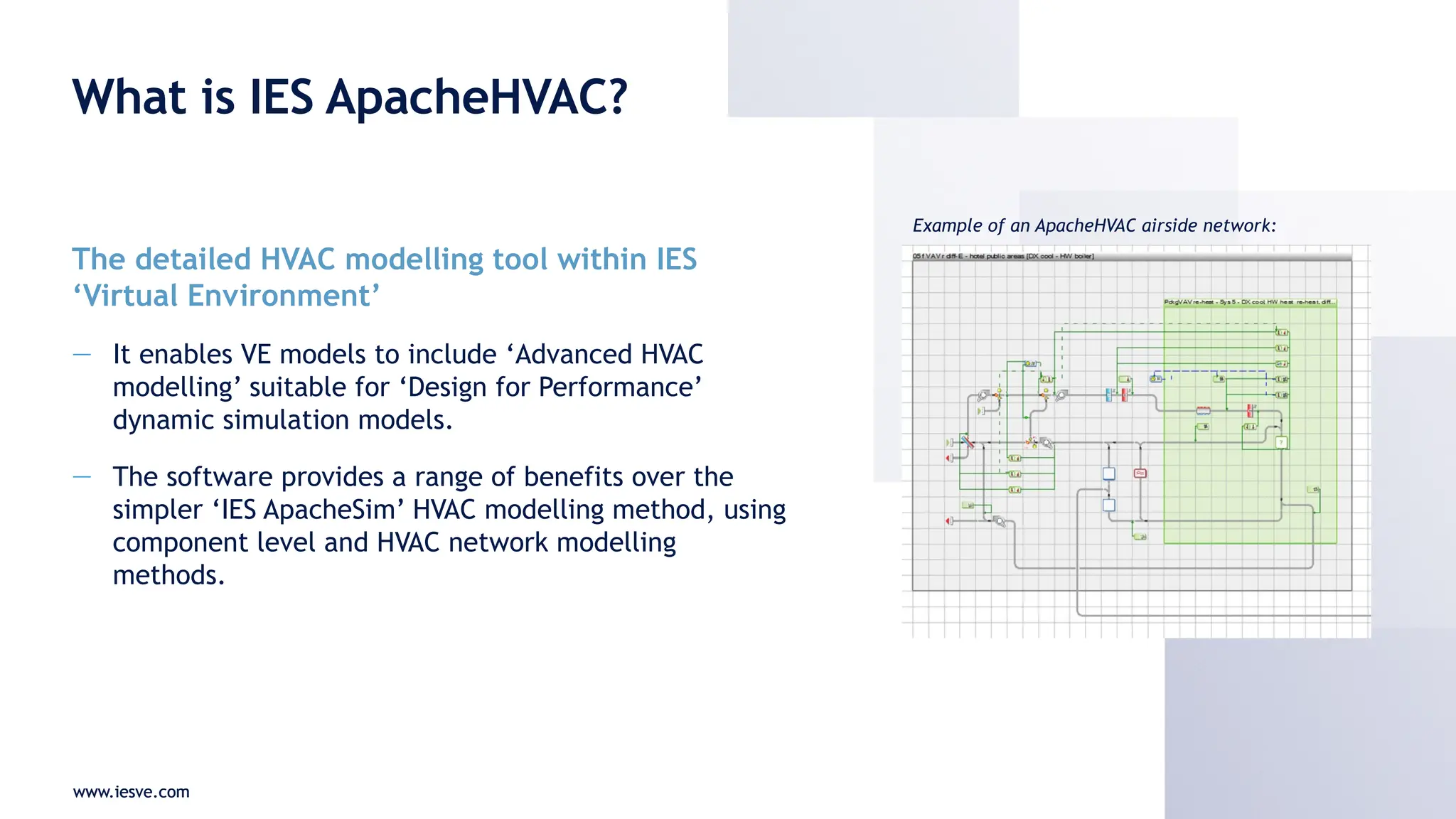

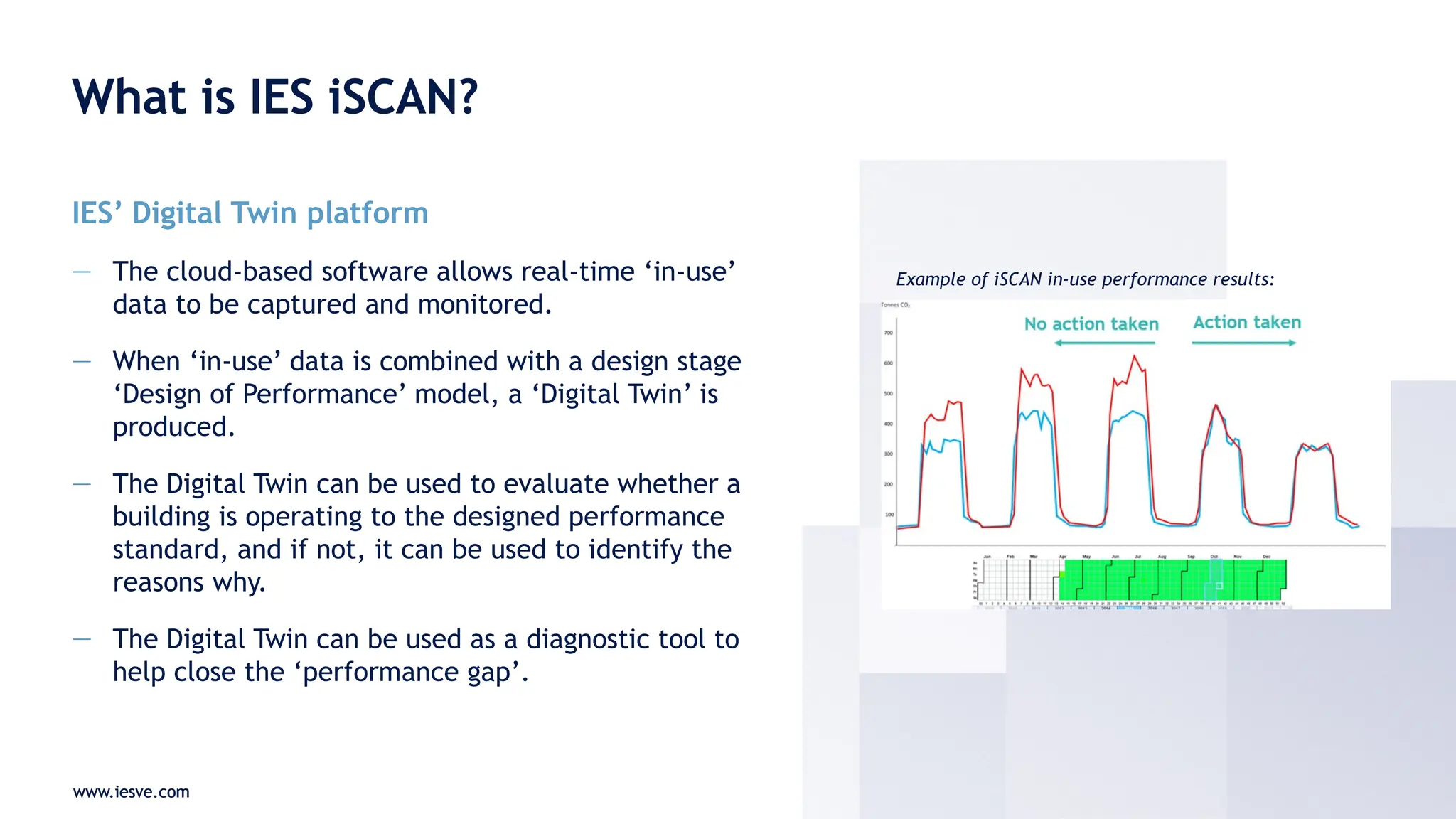

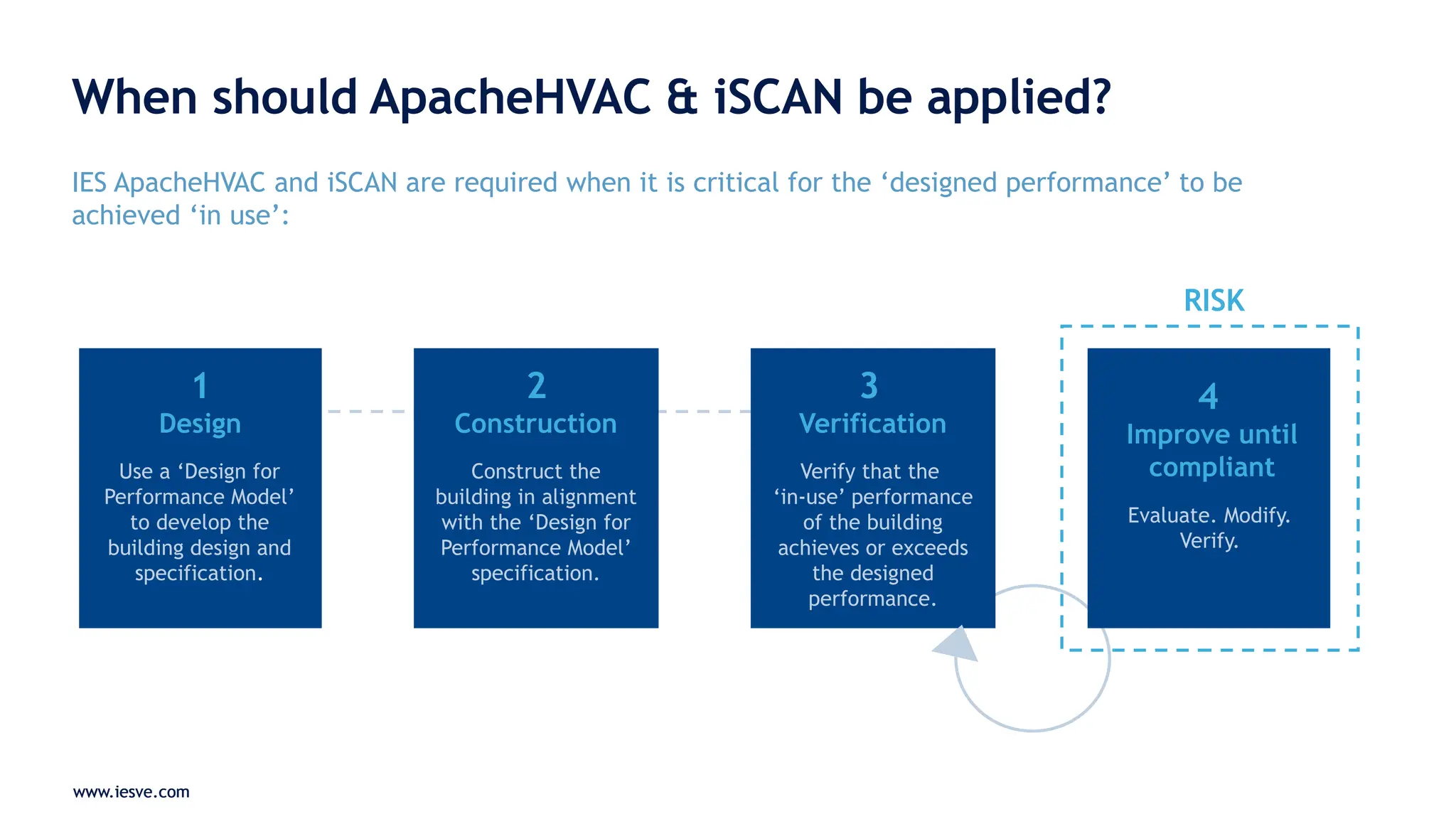

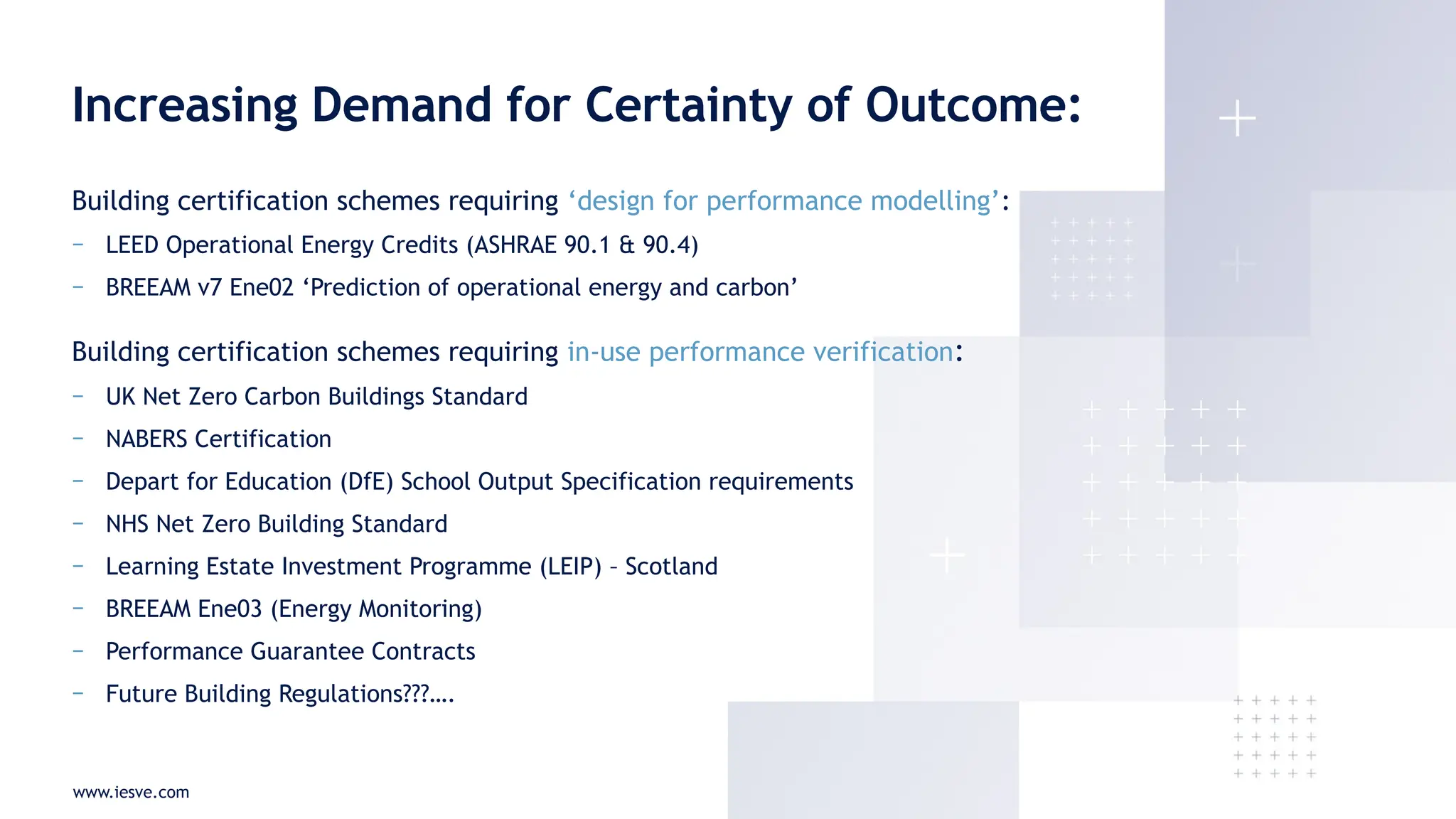

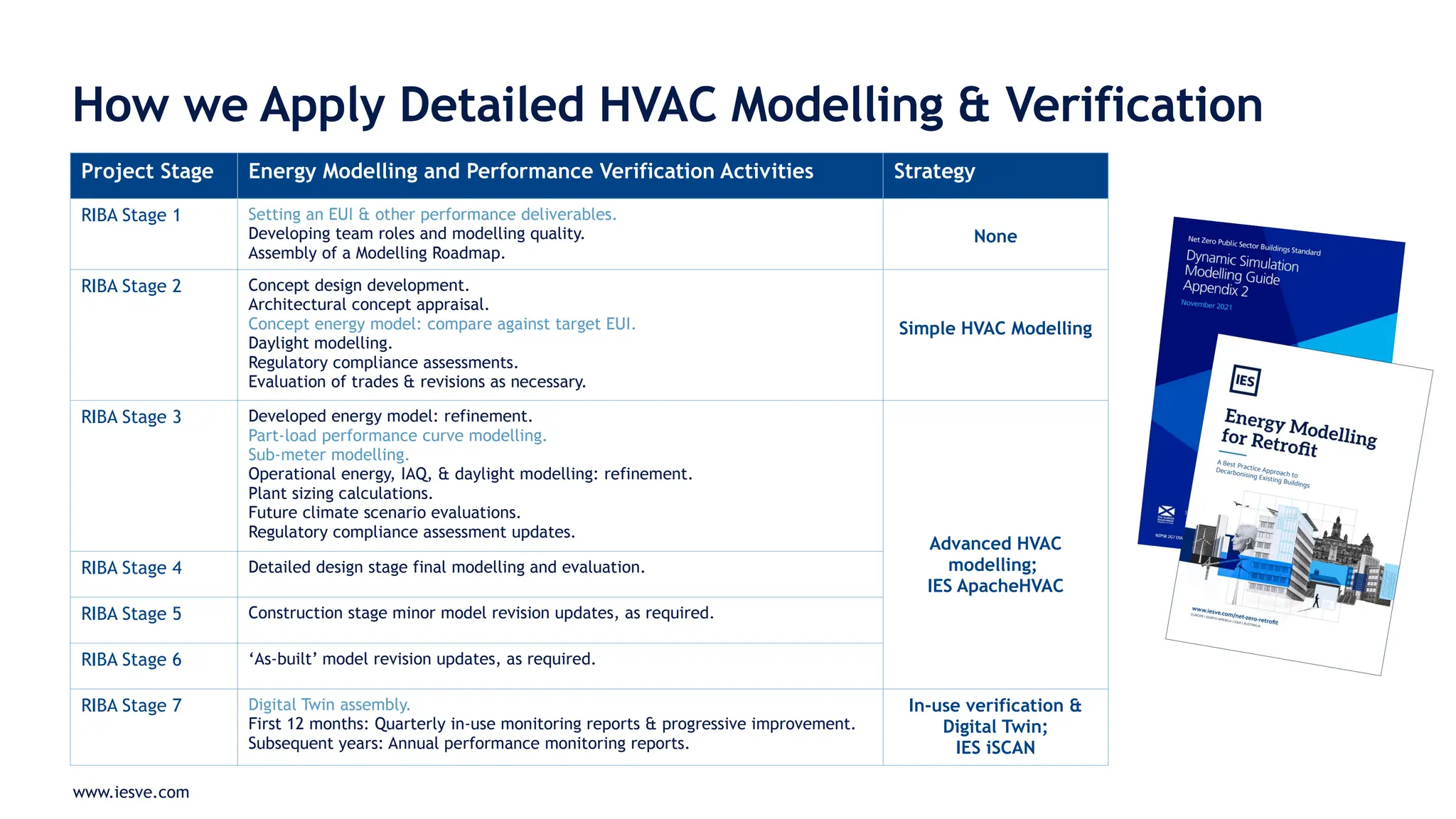

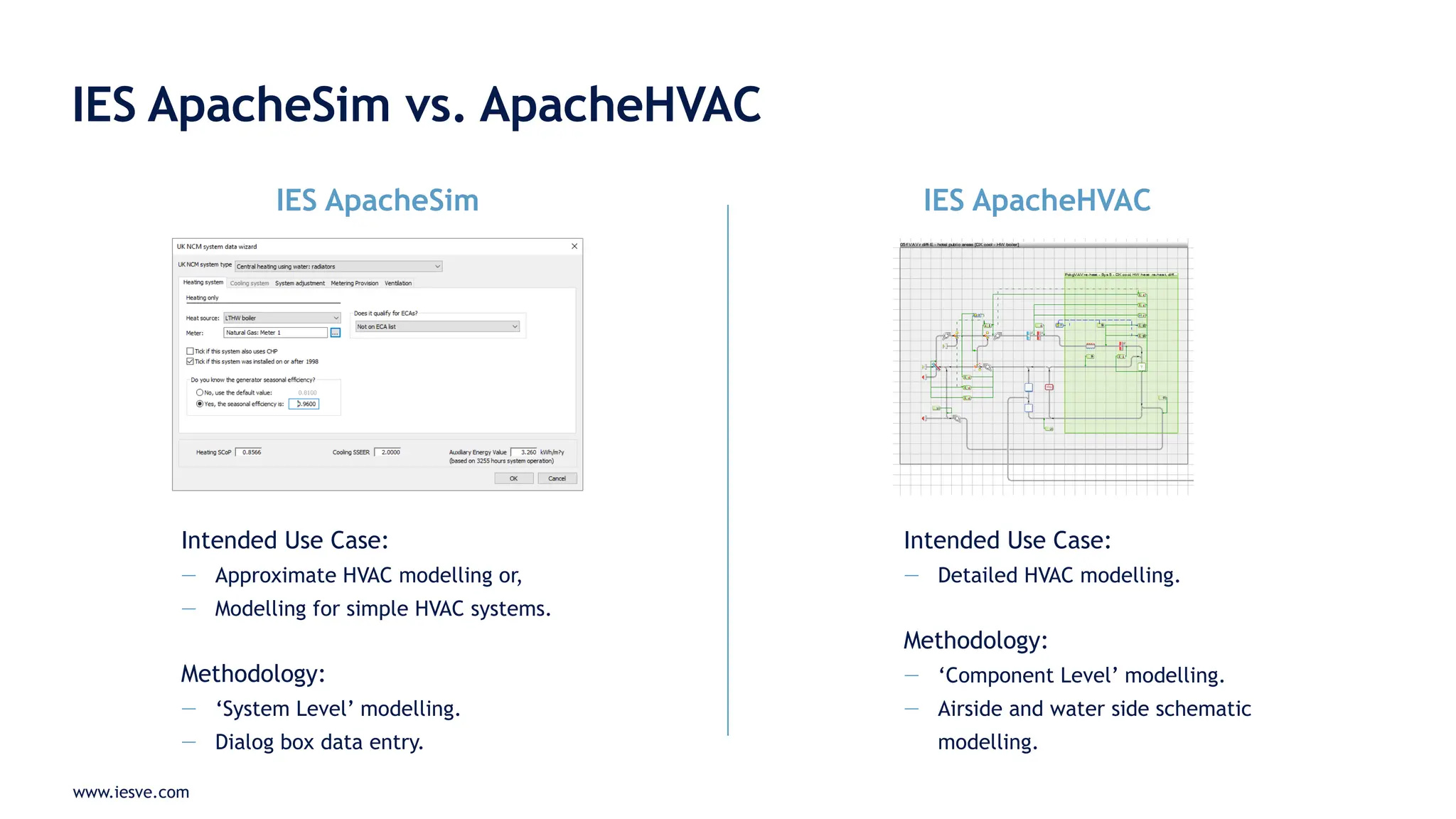

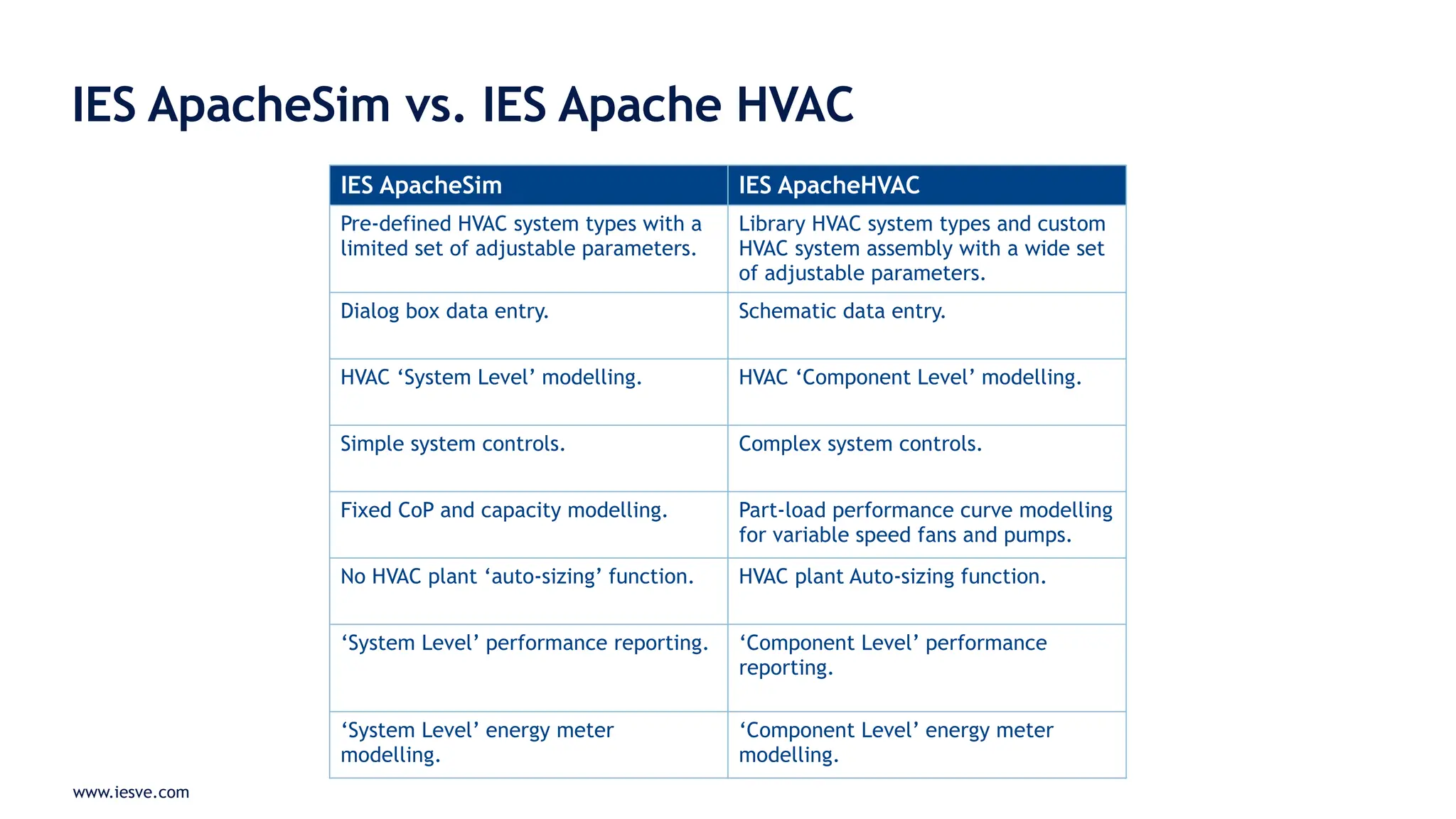

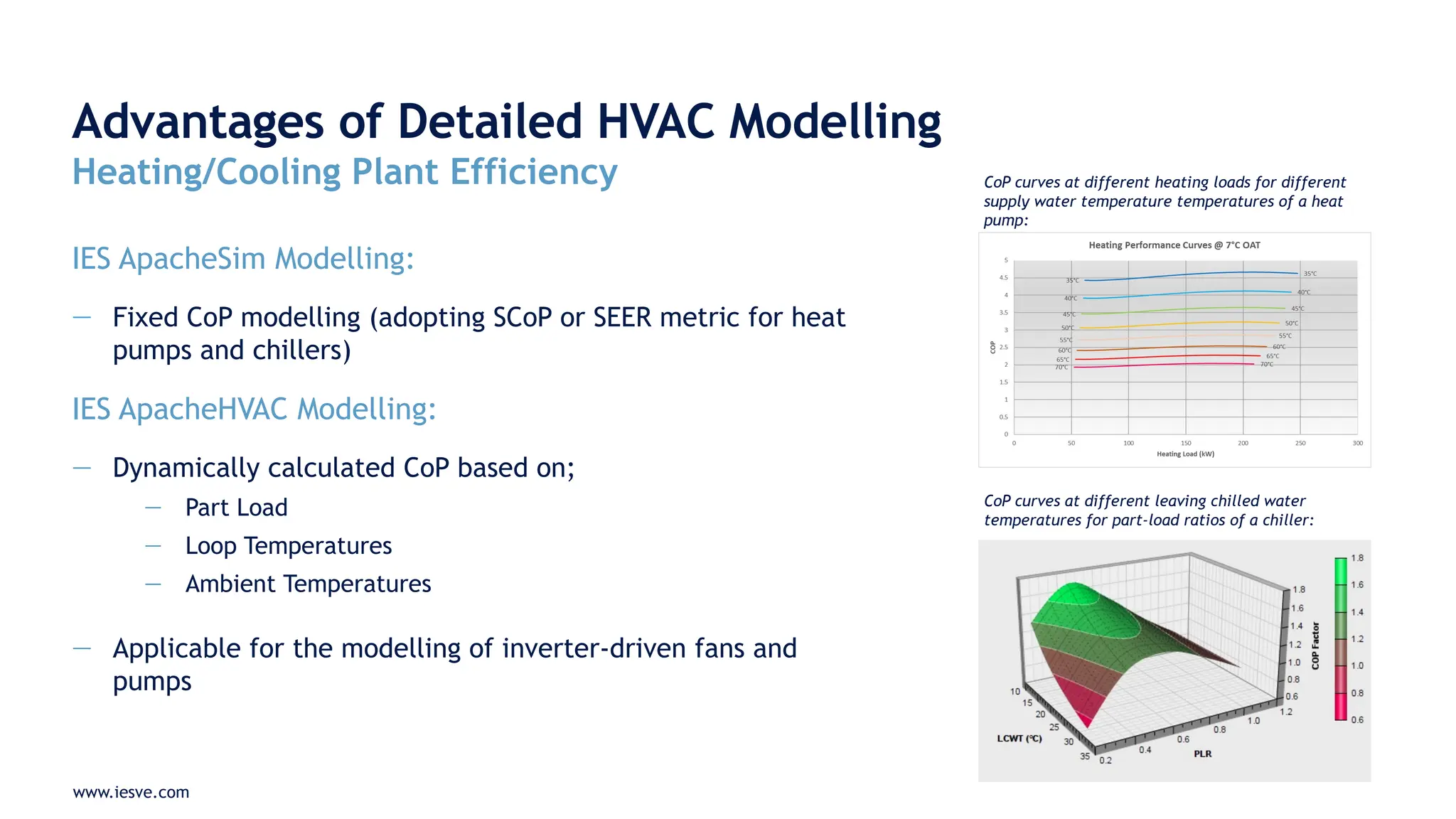

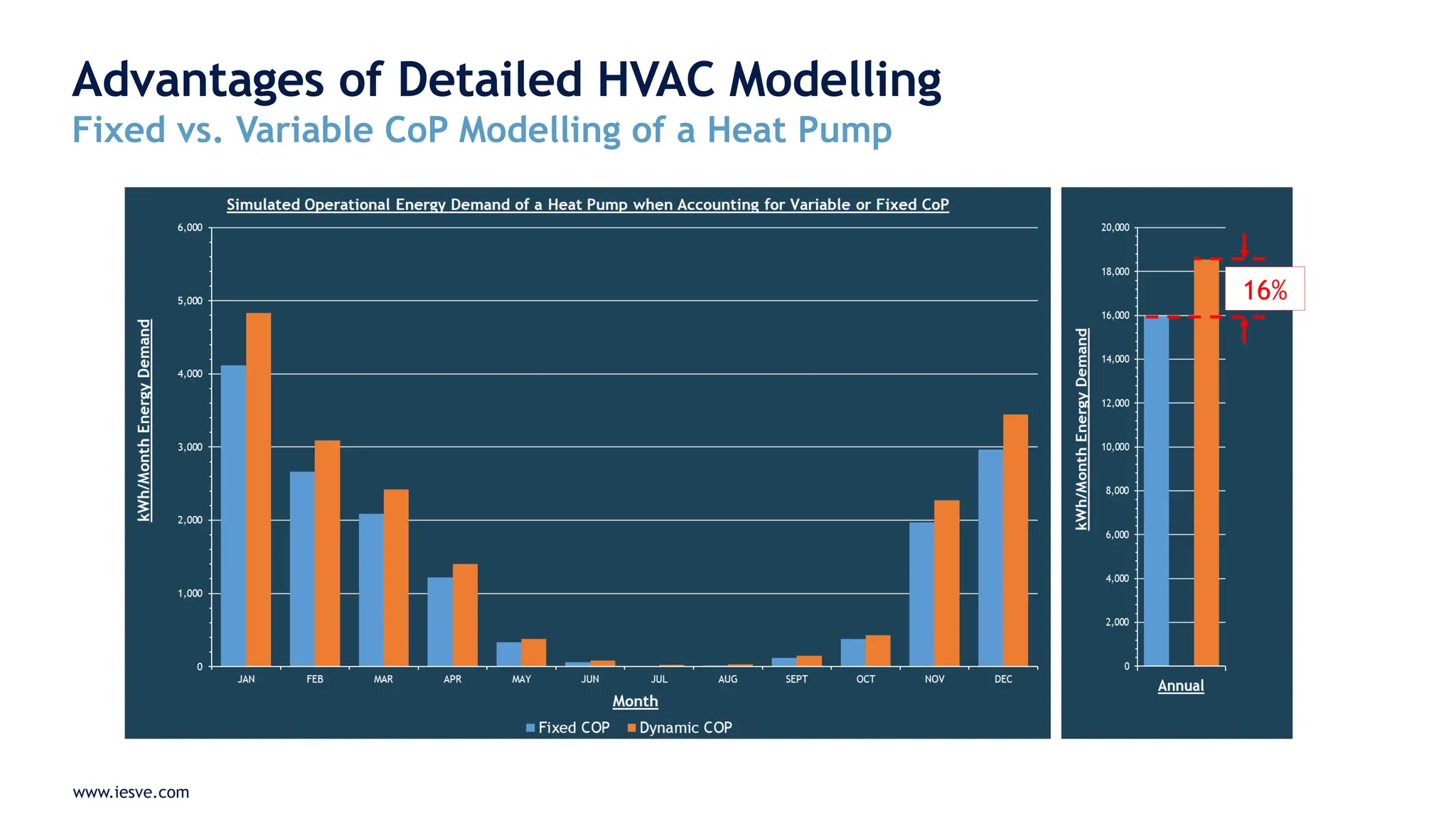

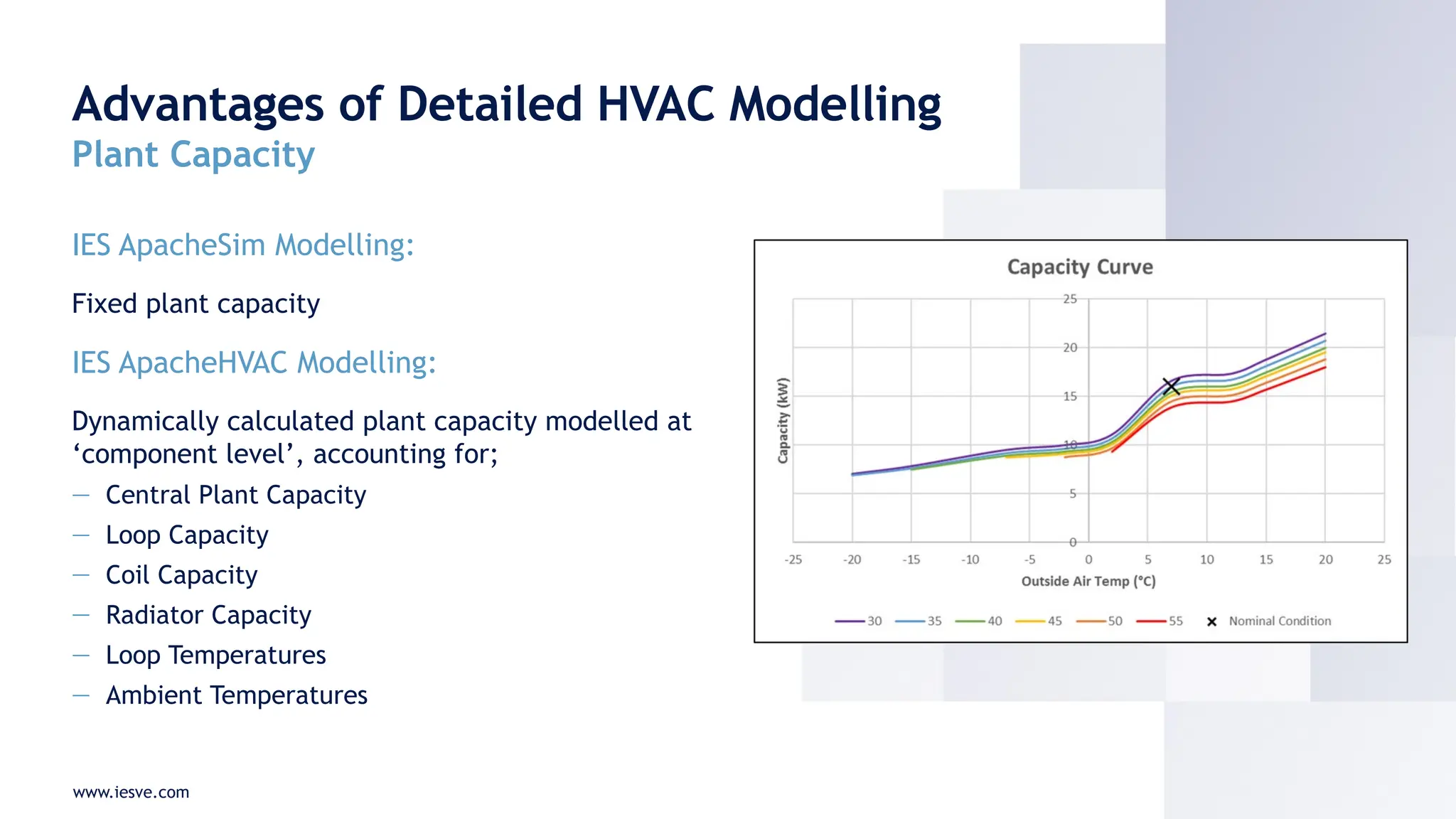

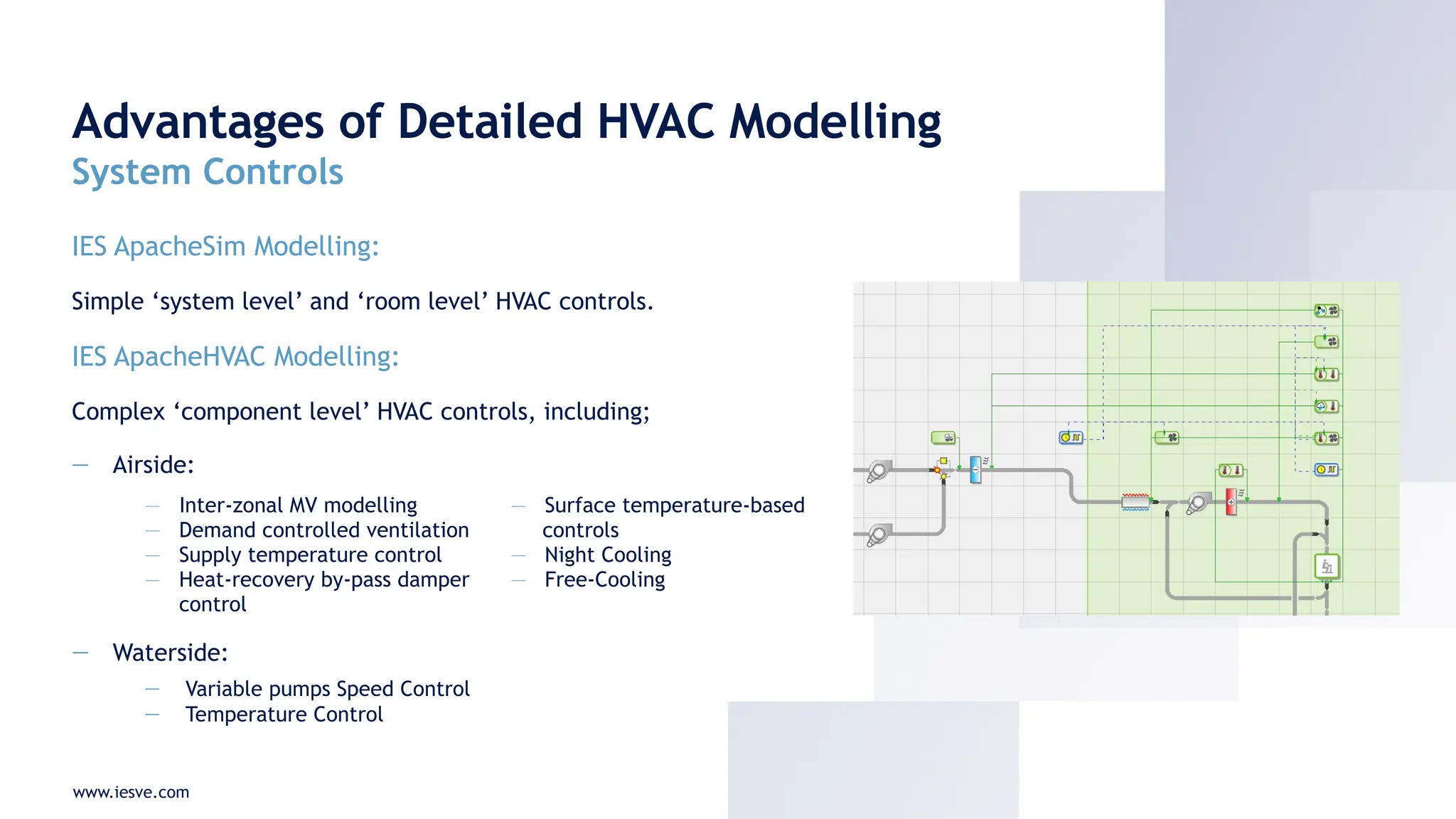

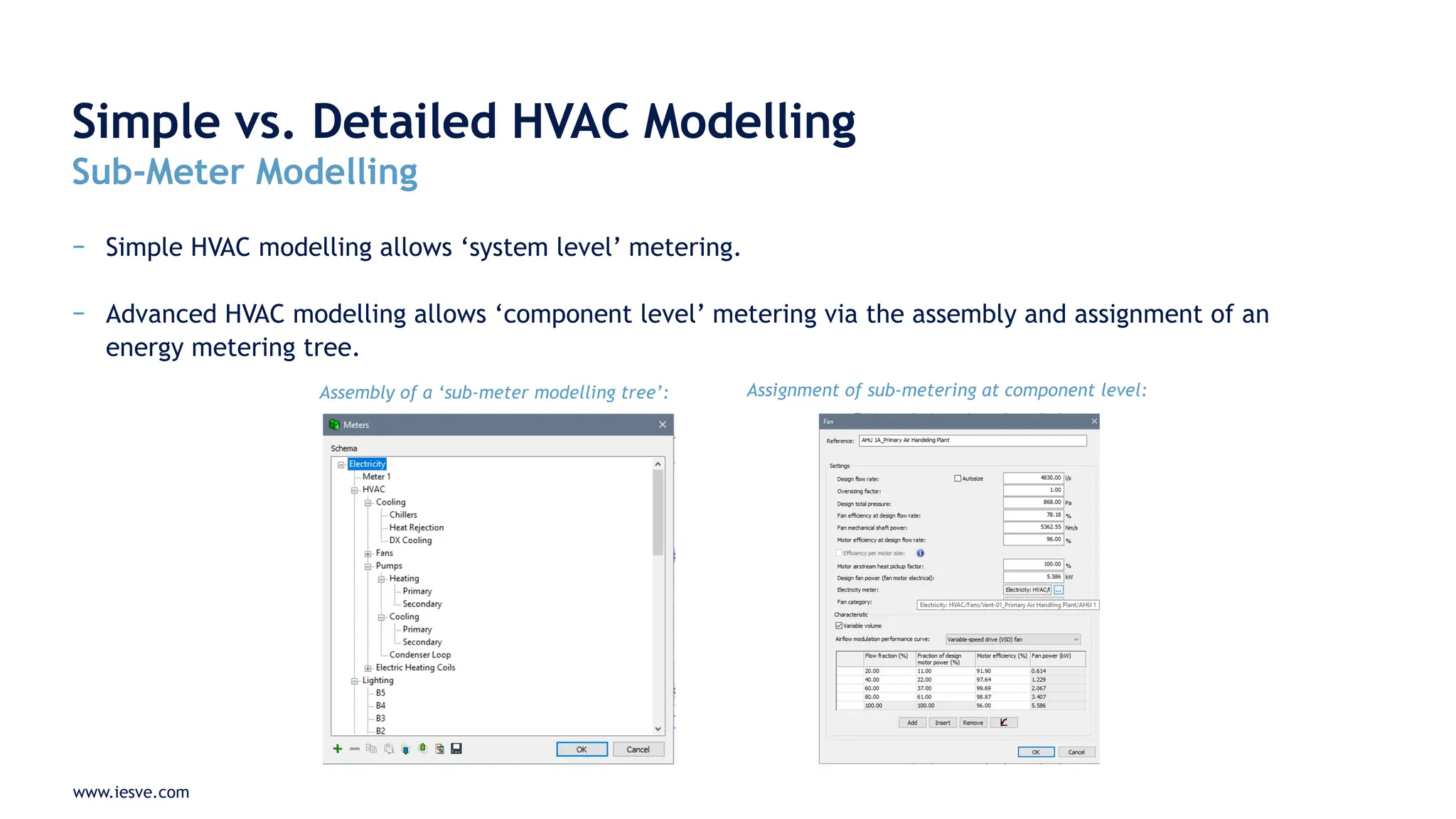

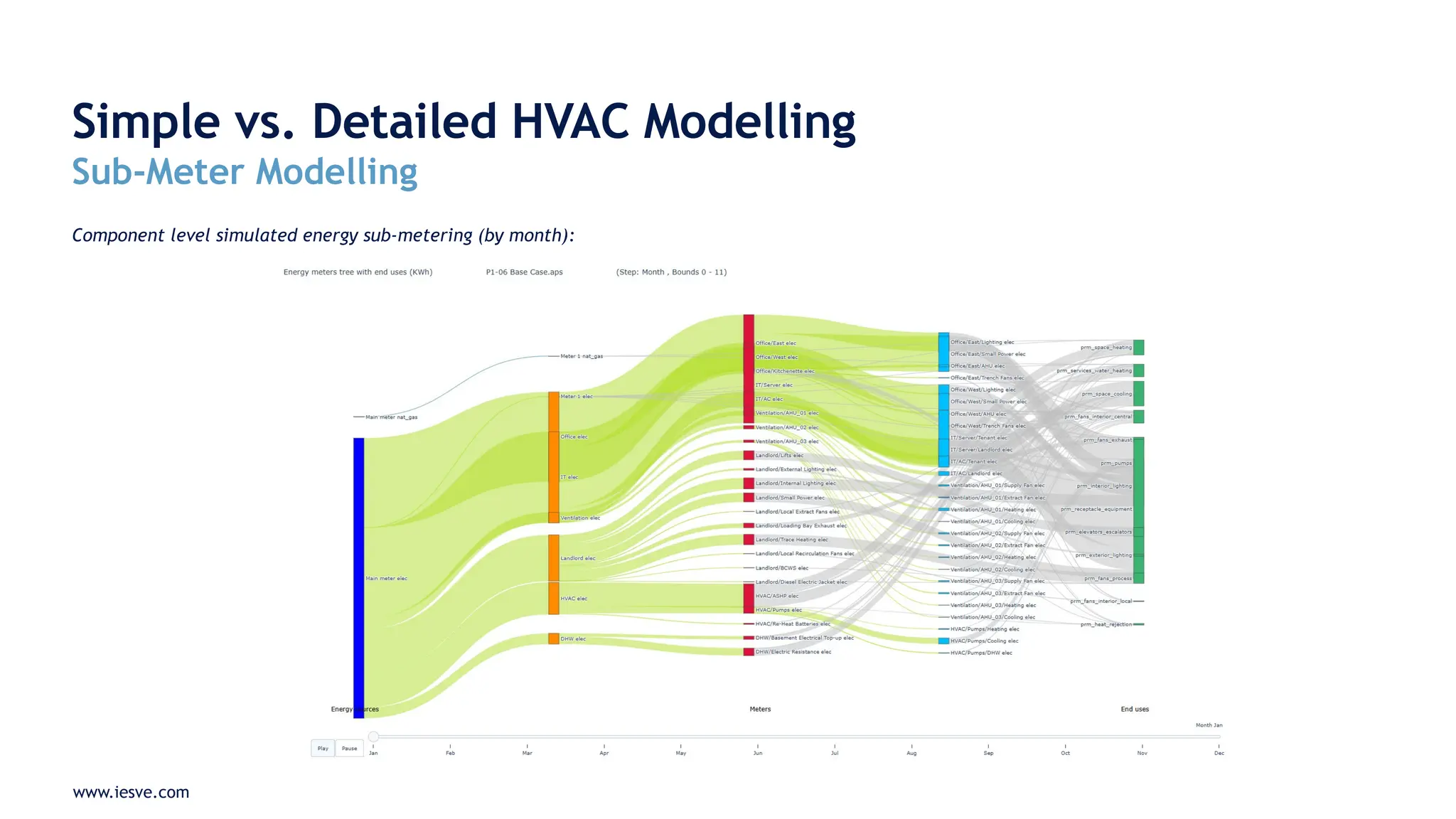

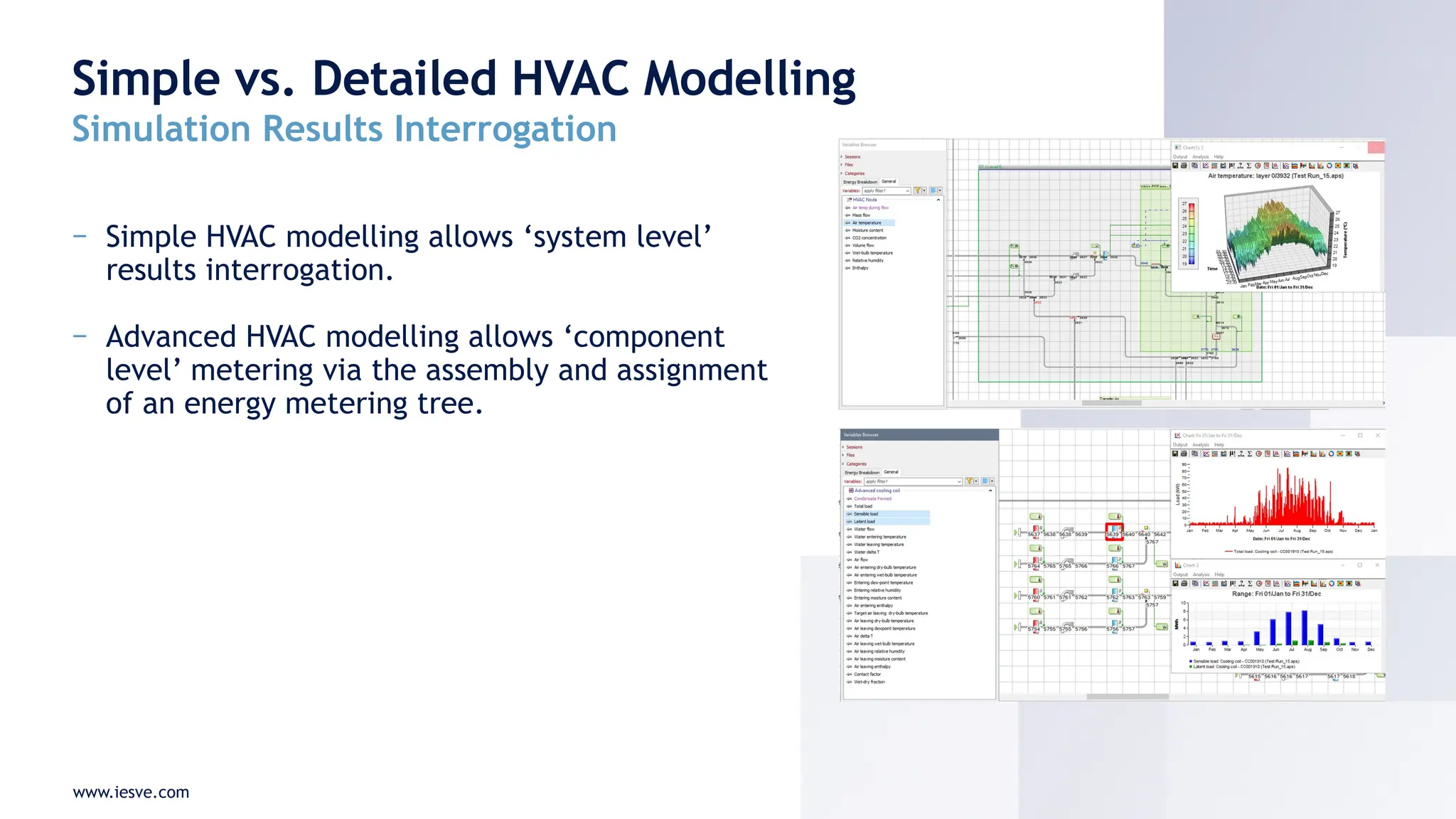

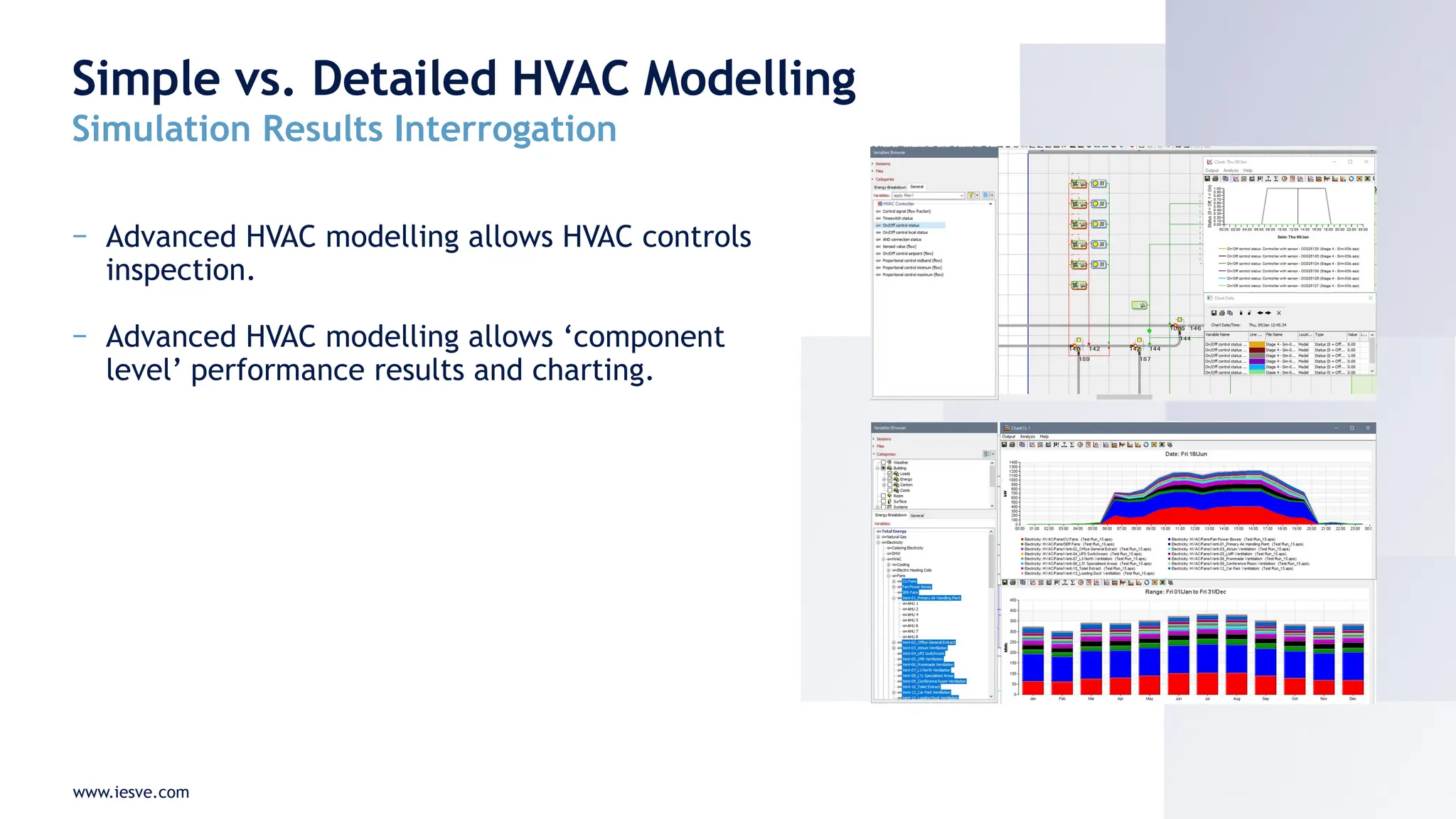

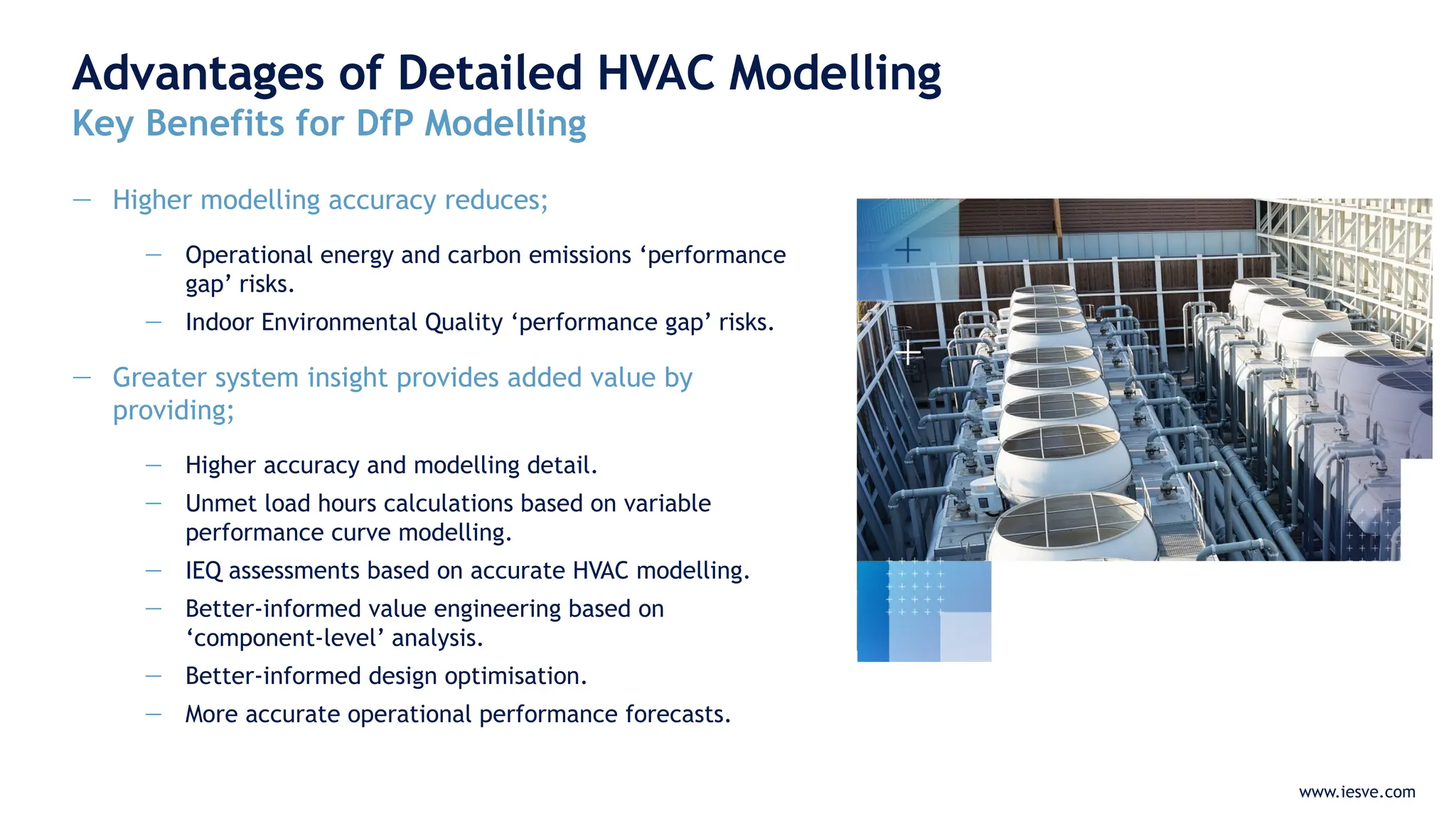

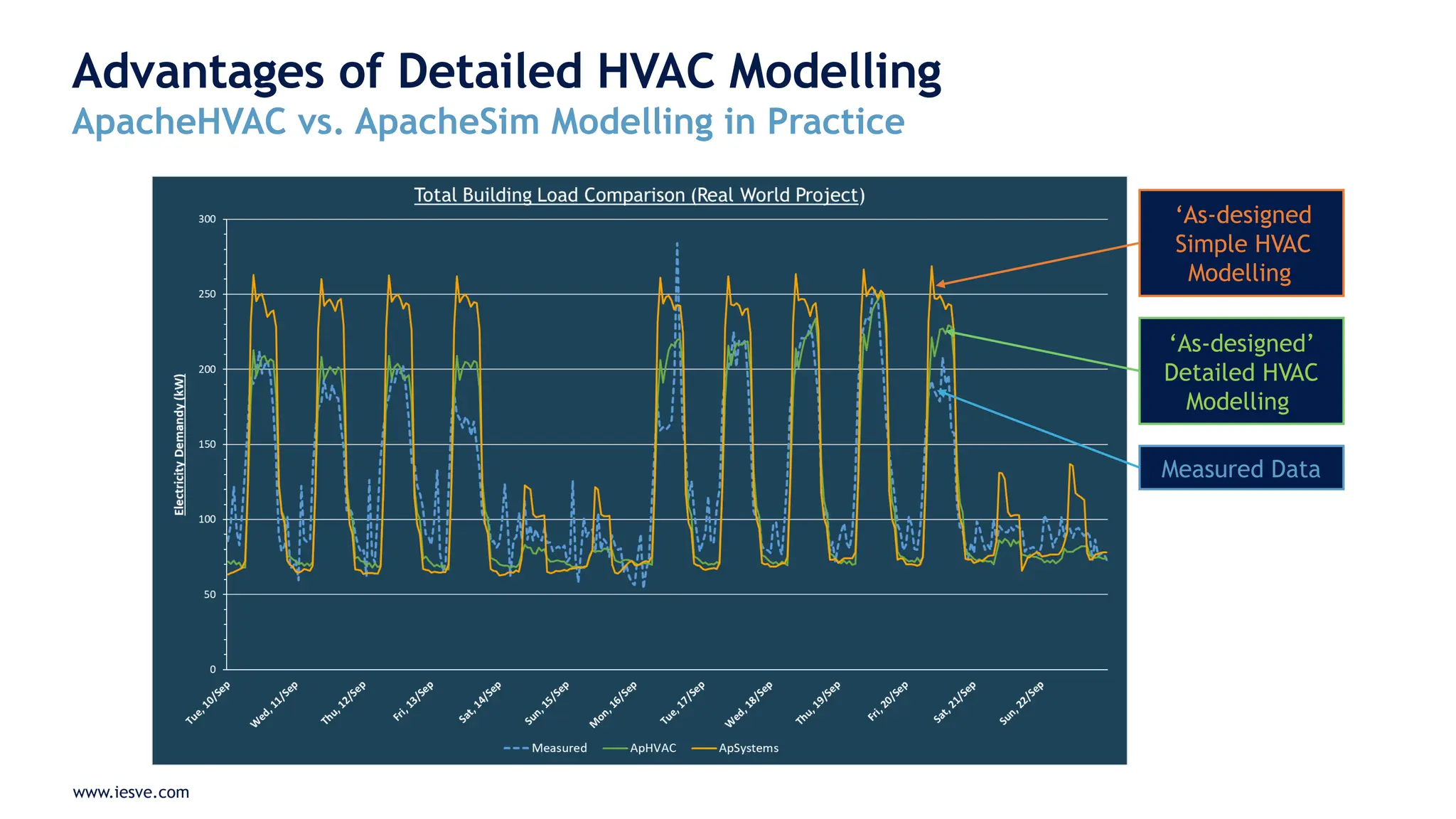

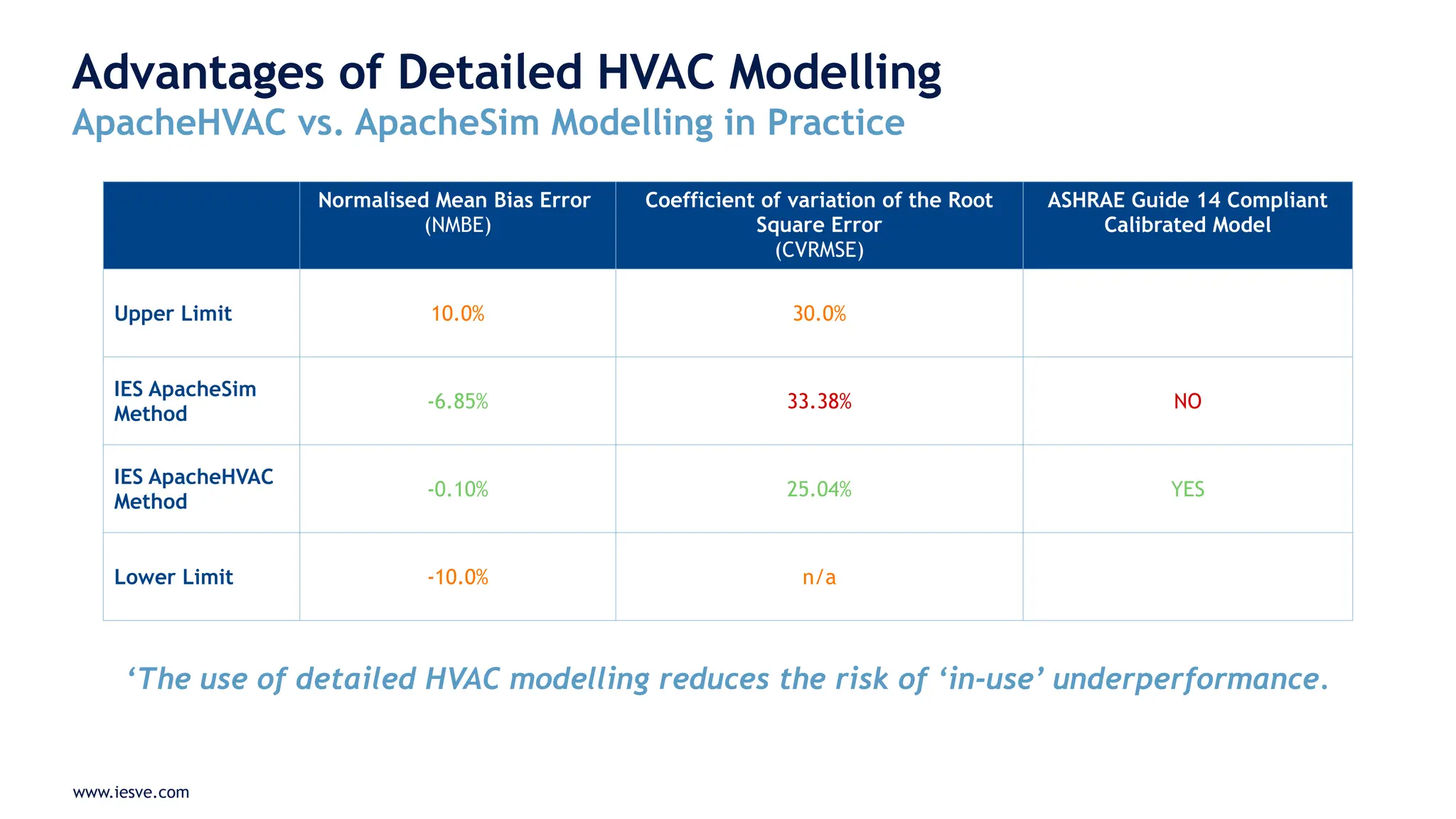

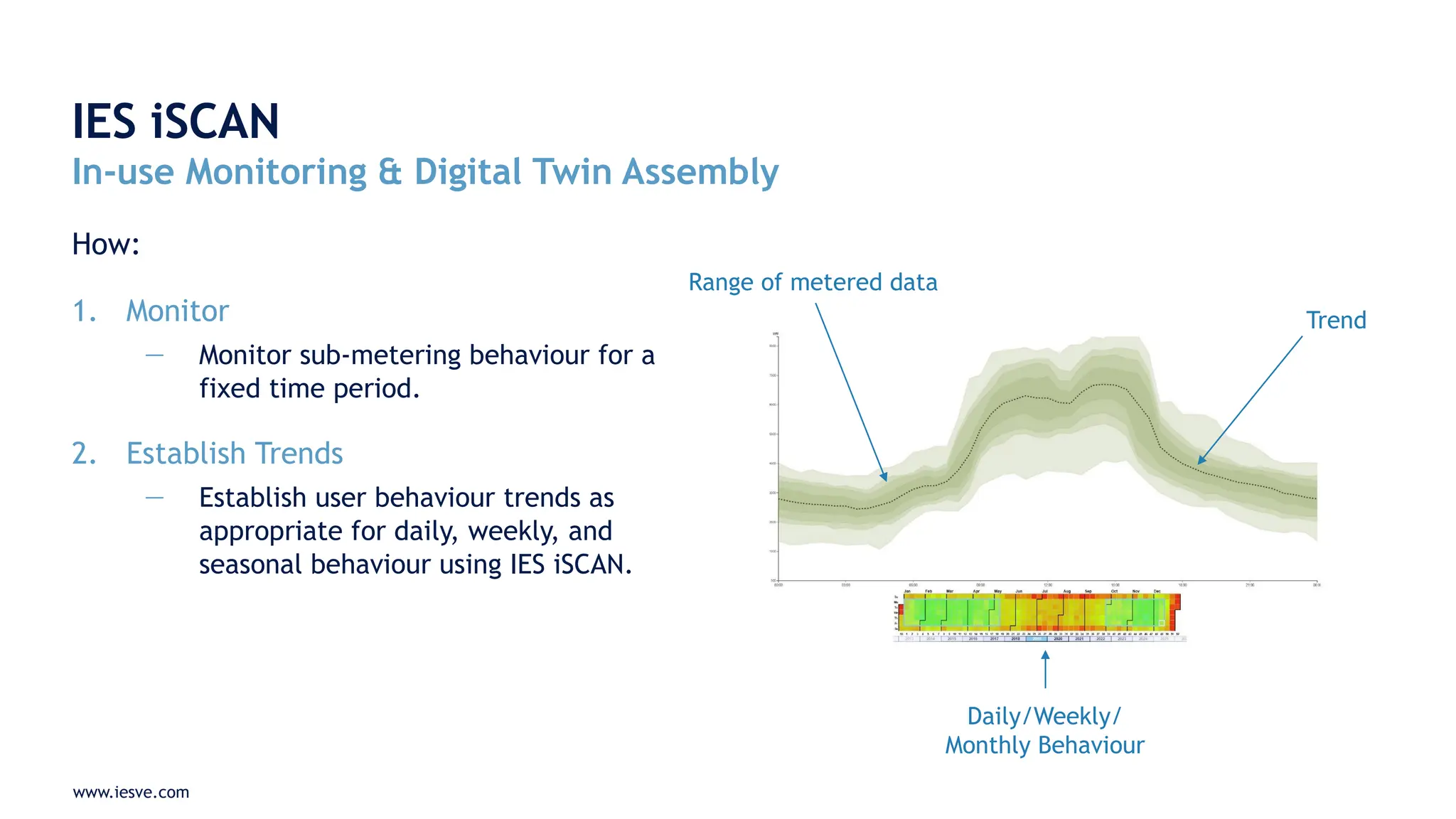

The document discusses how IES tools, specifically ApacheHVAC and ISCAN, can mitigate the risk of underperformance in HVAC systems through detailed modeling and real-time monitoring. ApacheHVAC provides advanced HVAC modeling for design performance, while ISCAN captures in-use data to create a digital twin, facilitating performance verification. The integration of these tools allows for ongoing monitoring and adjustments to ensure that buildings operate as intended, thus closing the performance gap.