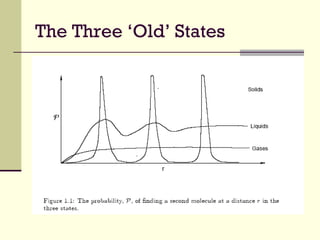

Nano-confined fluids exhibit layering and ordering behavior not seen in bulk fluids. X-ray reflectivity studies of polystyrene films with thicknesses less than the polymer's radius of gyration showed layering with periodicity matching the film thickness. Atomic force microscopy found the surface energy of these nano-confined films was spatially varying. This leads to a new state for nano-confined fluids with low out-of-plane cohesion but tunable in-plane self-assembly of gold nanoparticles controlled by film thickness.