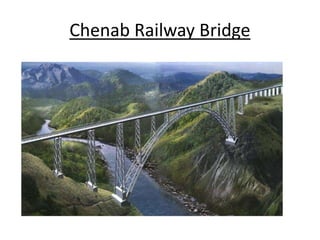

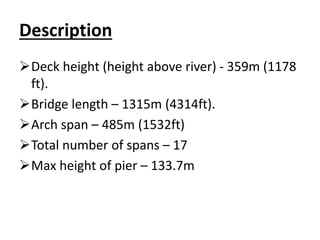

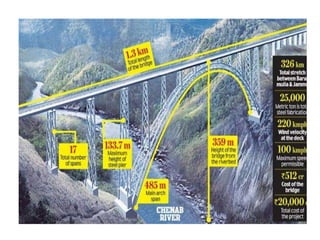

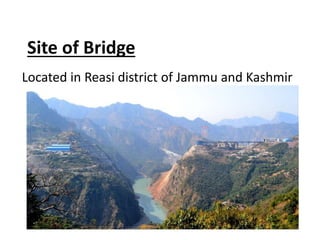

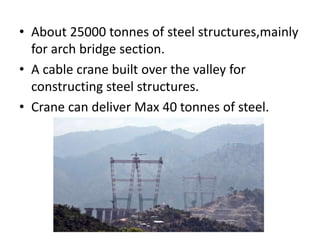

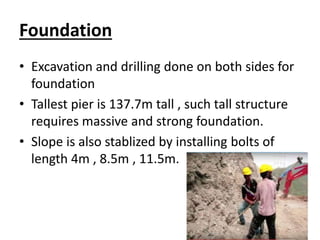

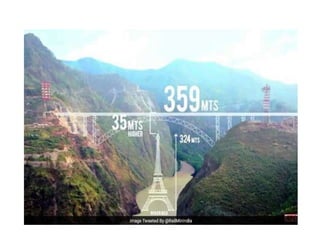

The Chenab Railway Bridge is a steel and concrete arch bridge that is under construction in Jammu and Kashmir, India. It will be part of a new railway line connecting Jammu to Kashmir. At 359 meters in height above the Chenab River, it will be the highest railway bridge in the world once completed. The bridge is 1,315 meters long with a main arch span of 485 meters and 17 total spans. It is being built to improve connectivity in the difficult terrain and provide safer travel between Jammu and Kashmir. Construction has faced challenges due to the region's harsh weather and poor geology but is expected to be finished by 2022.