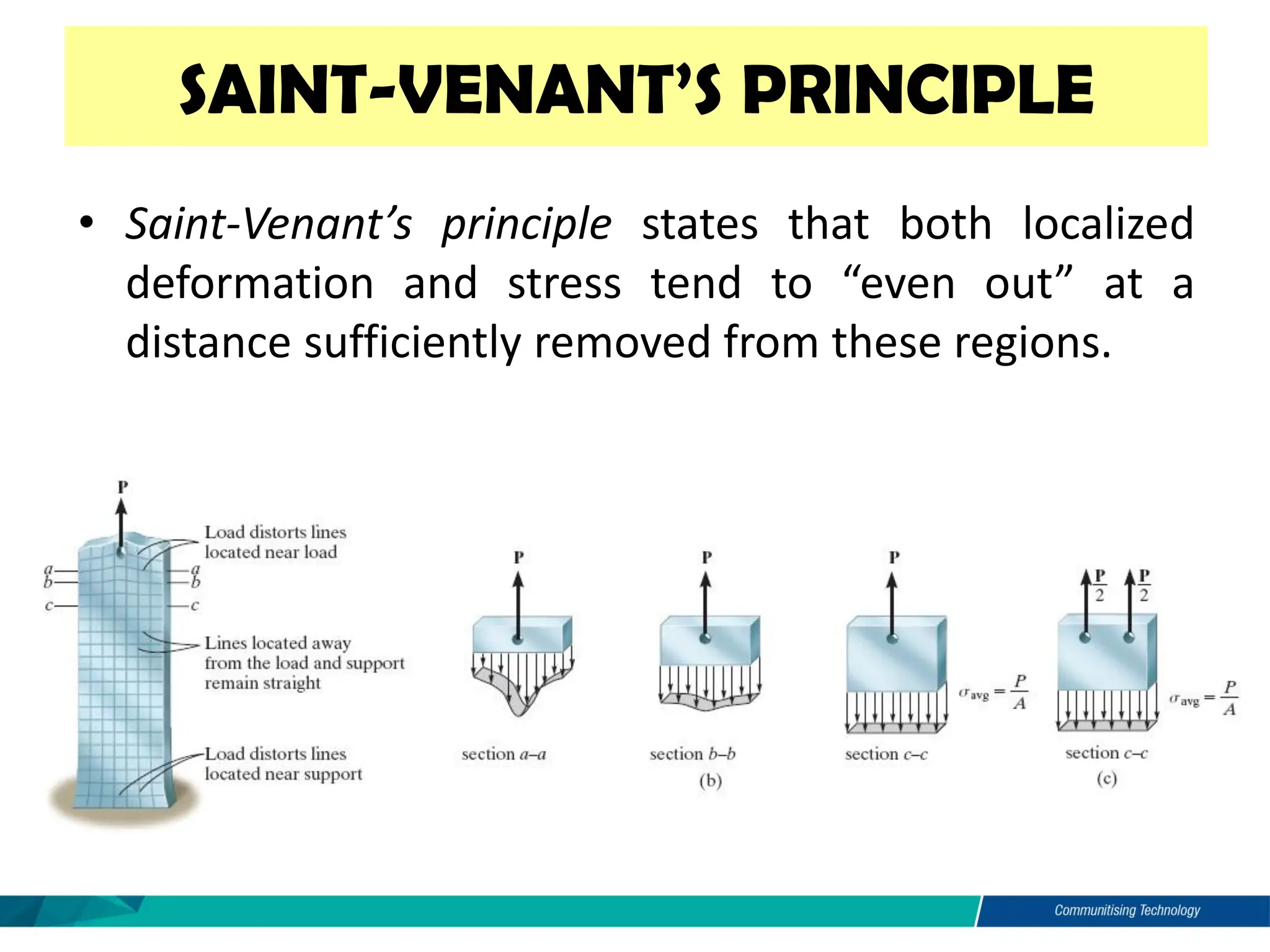

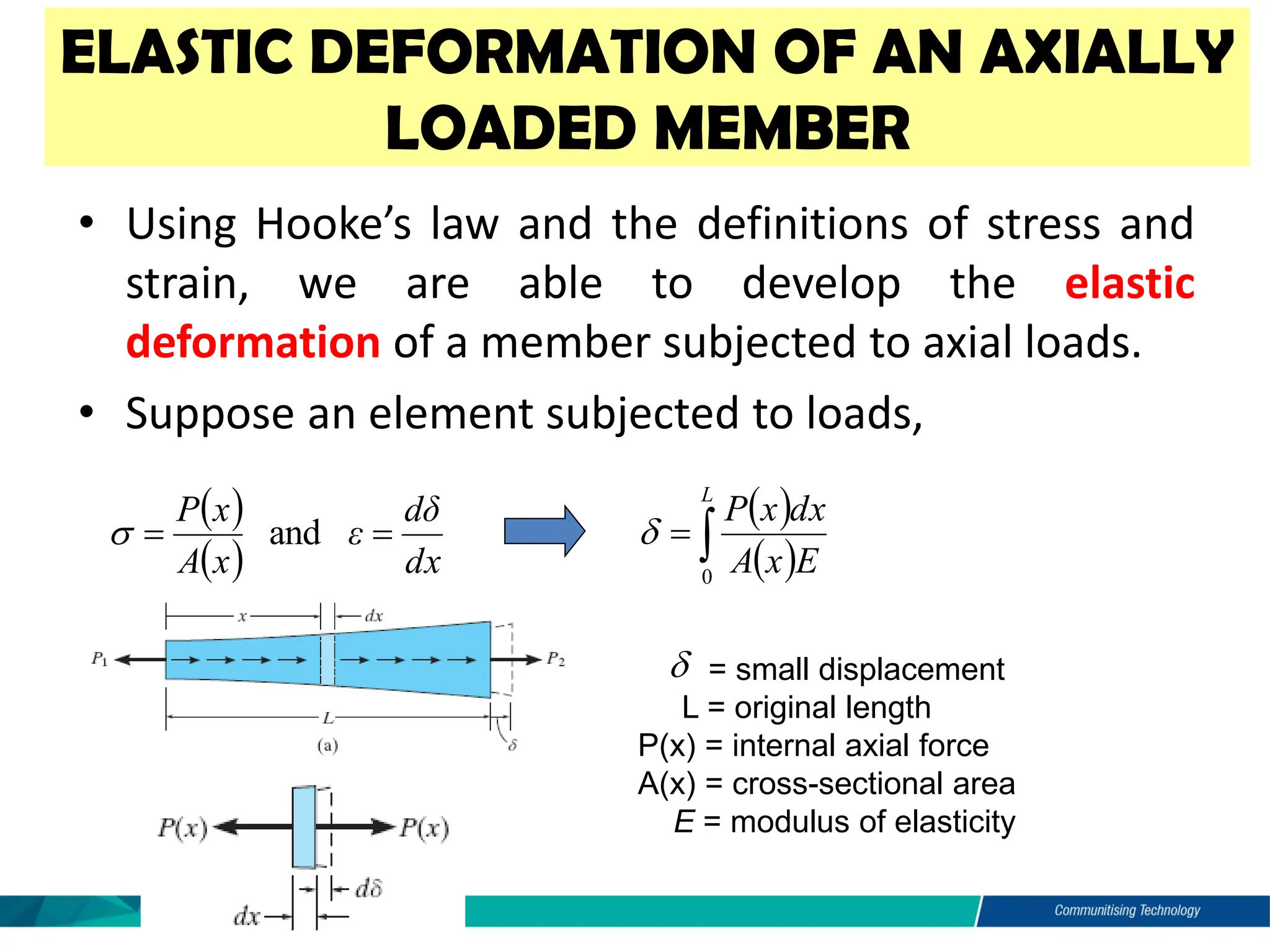

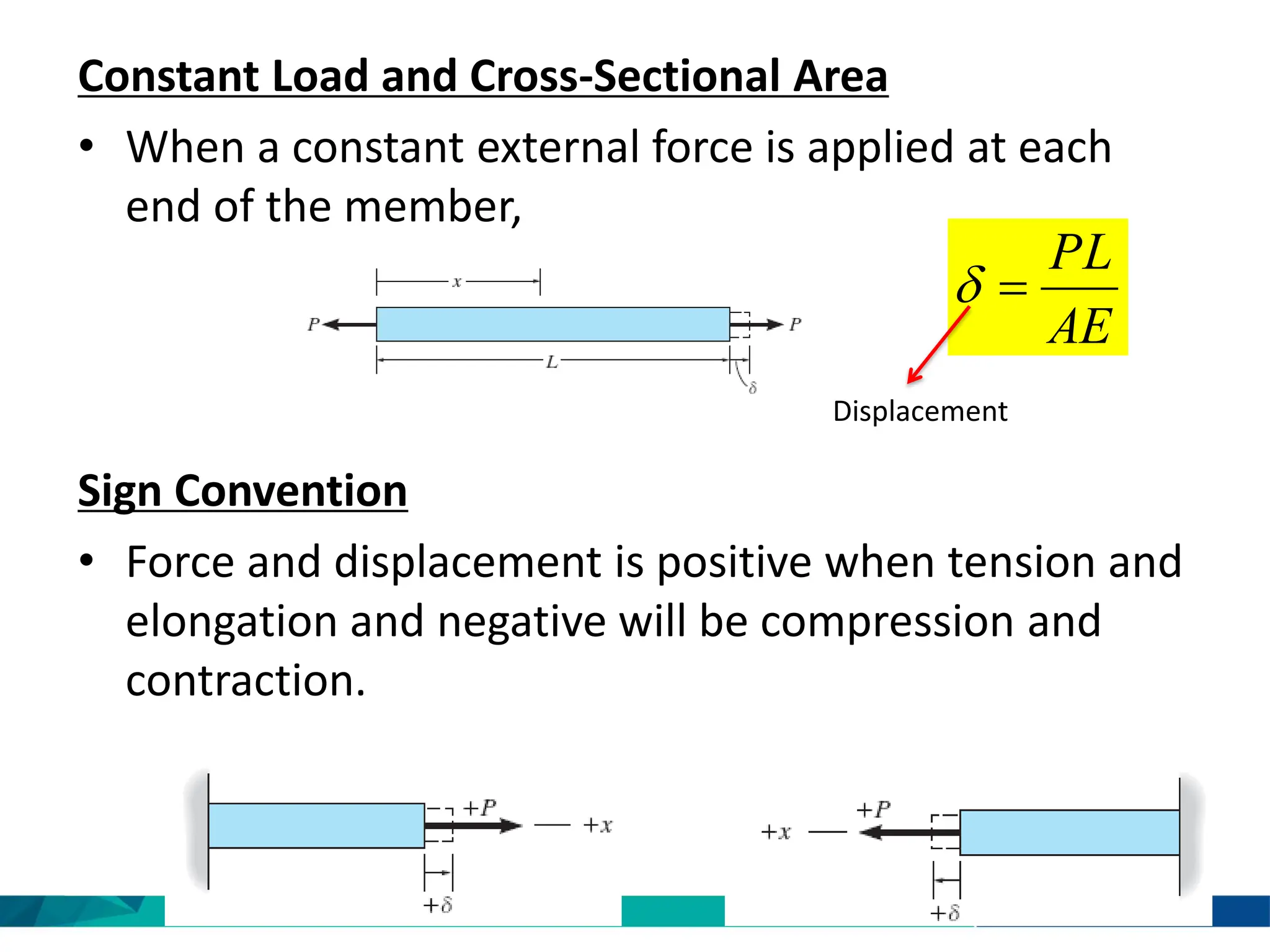

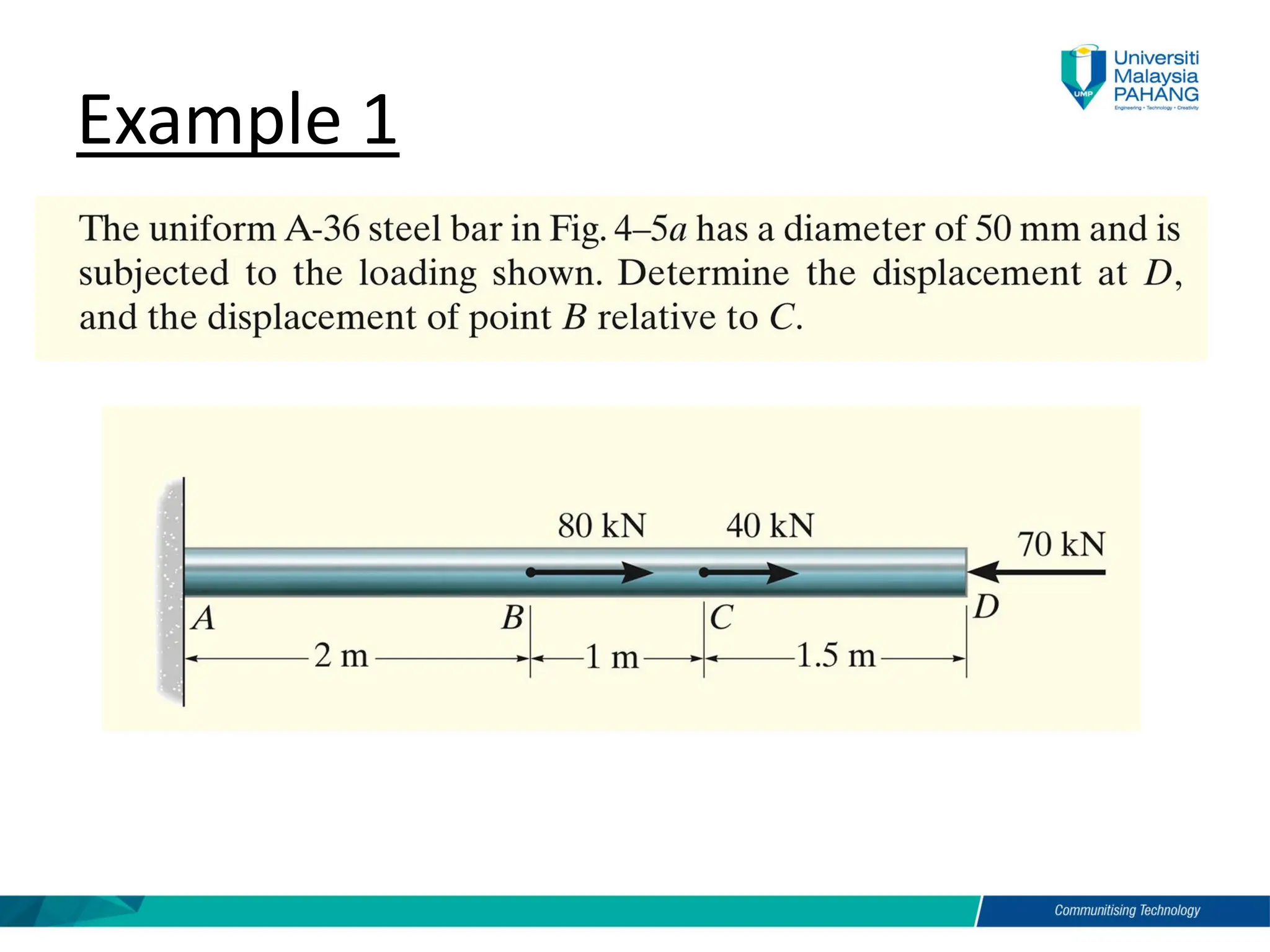

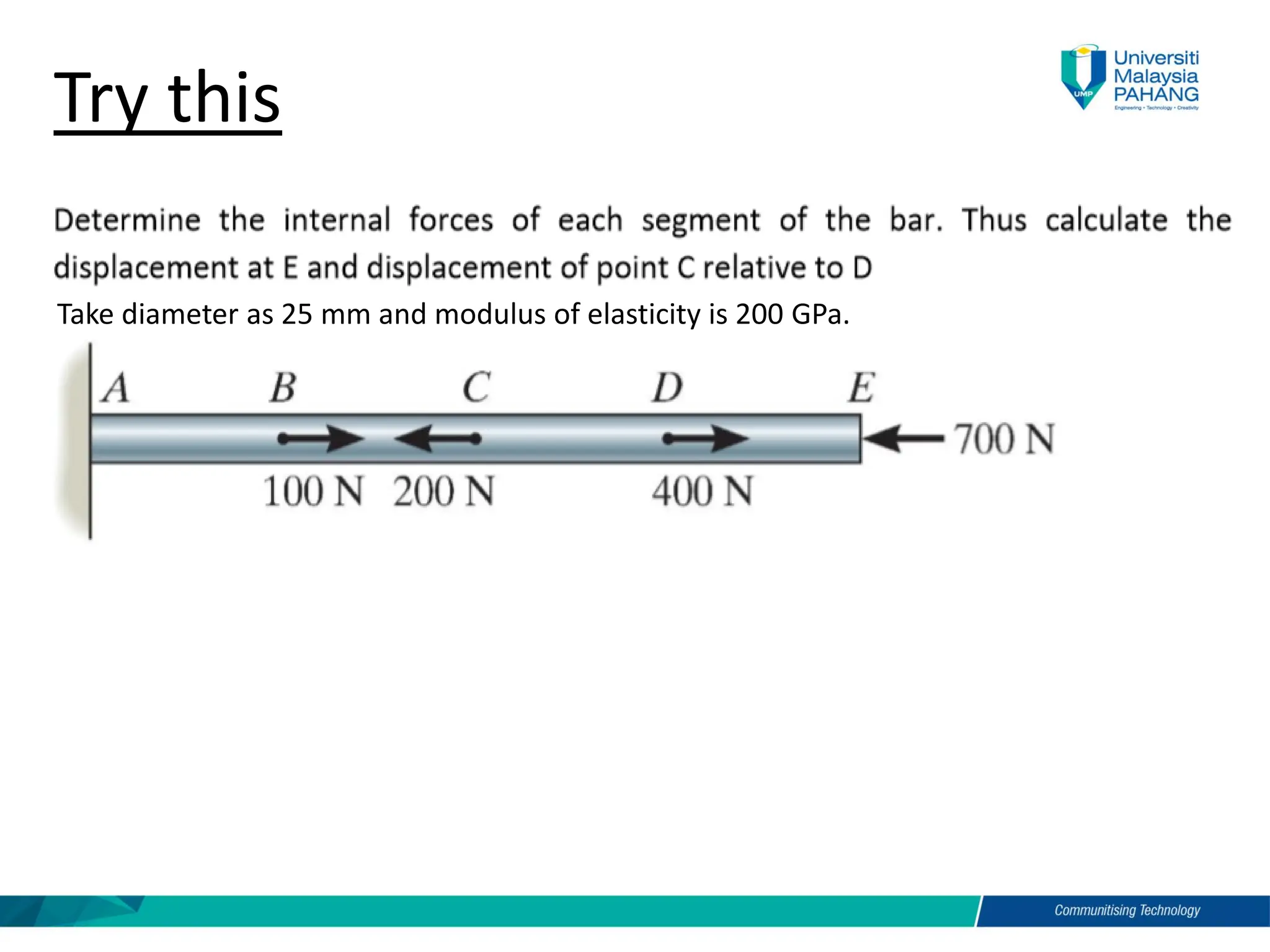

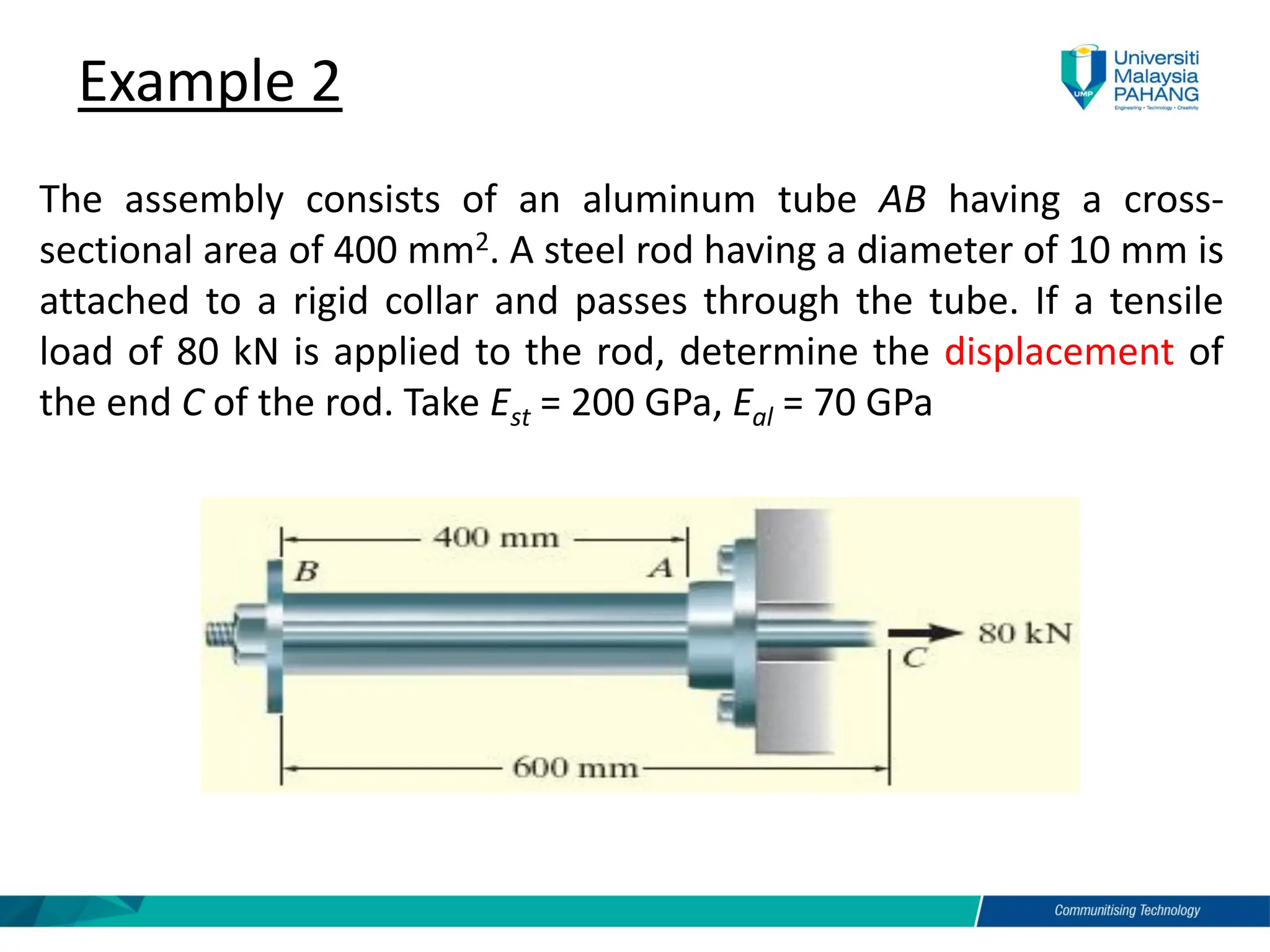

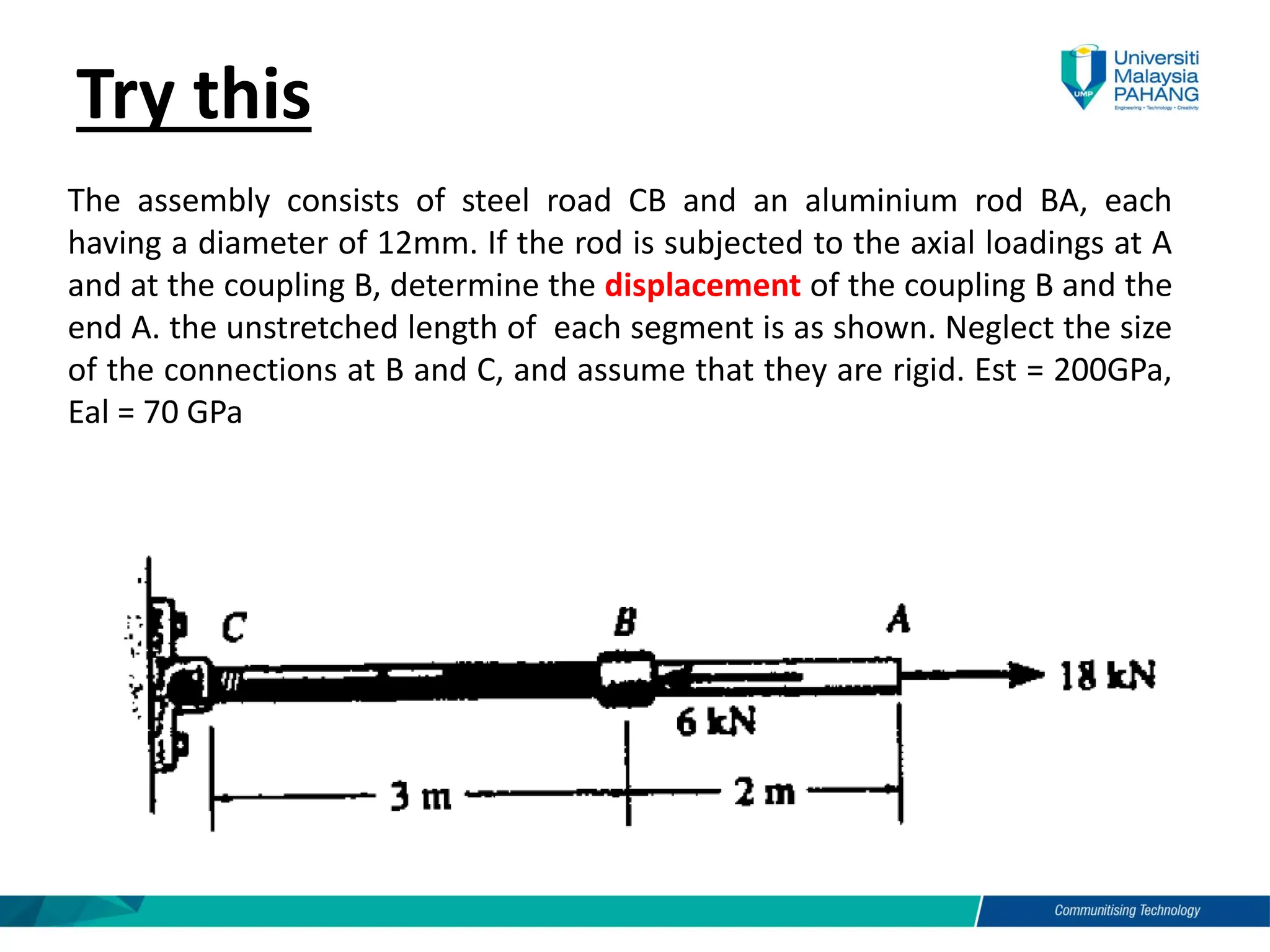

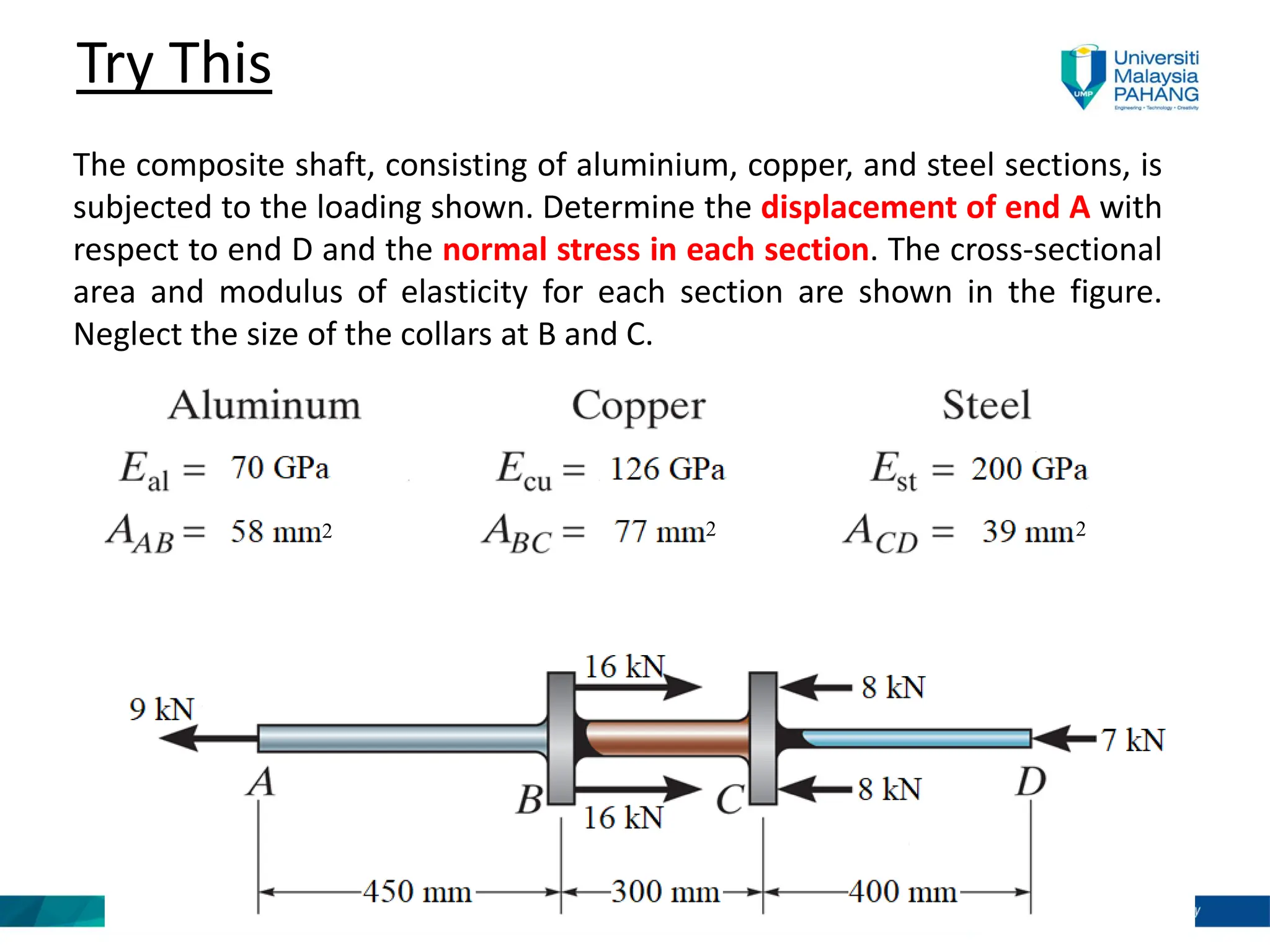

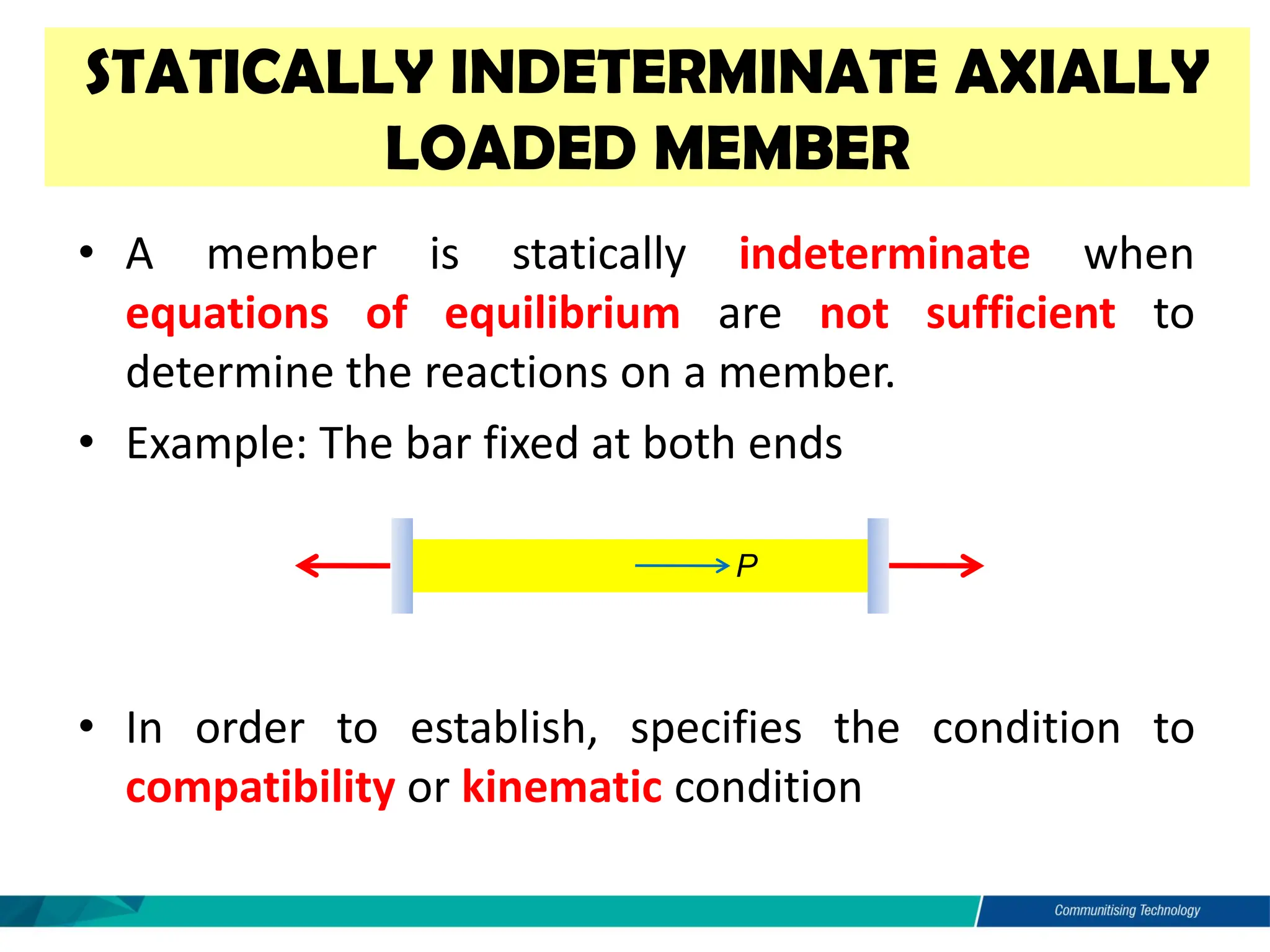

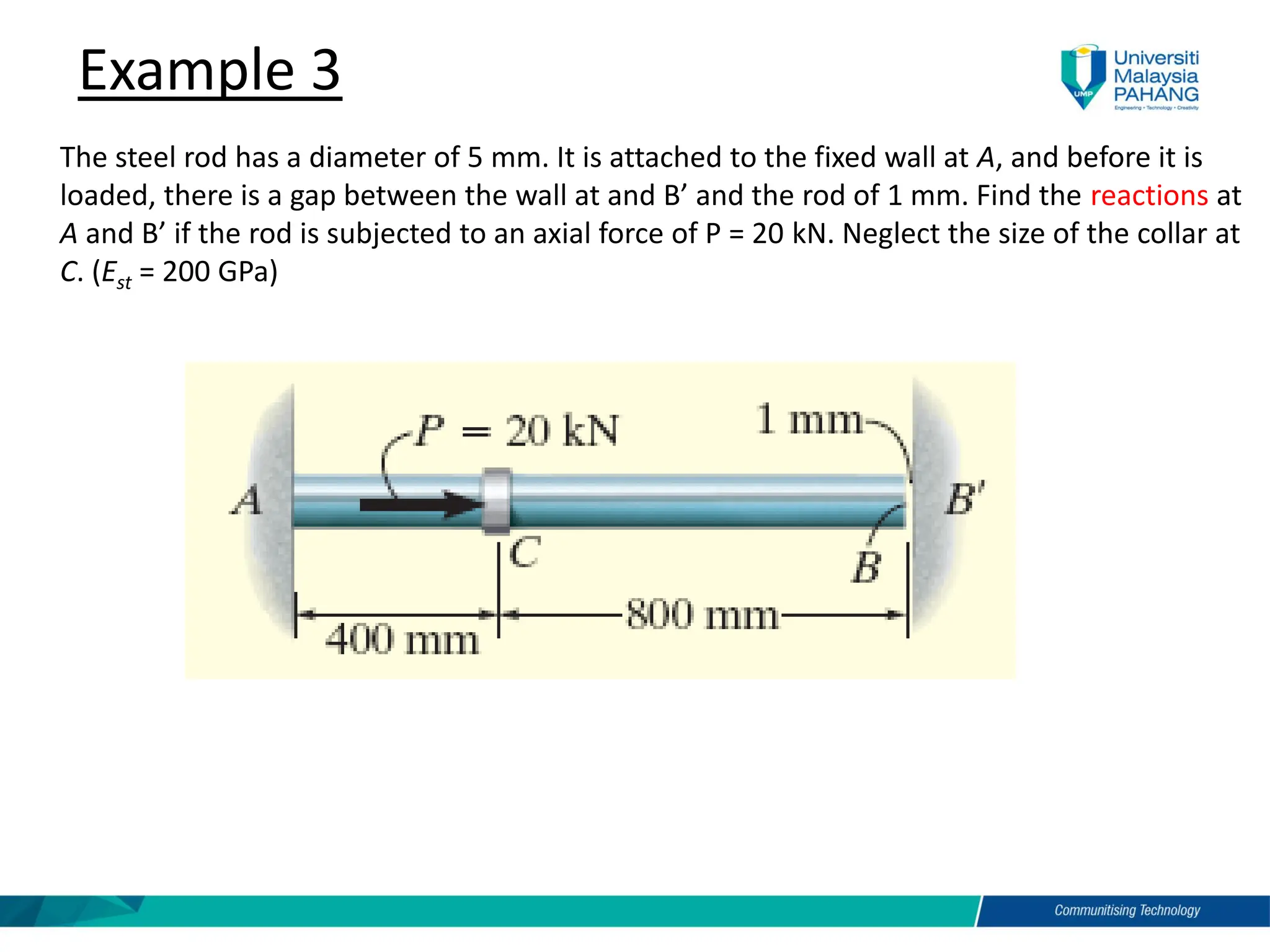

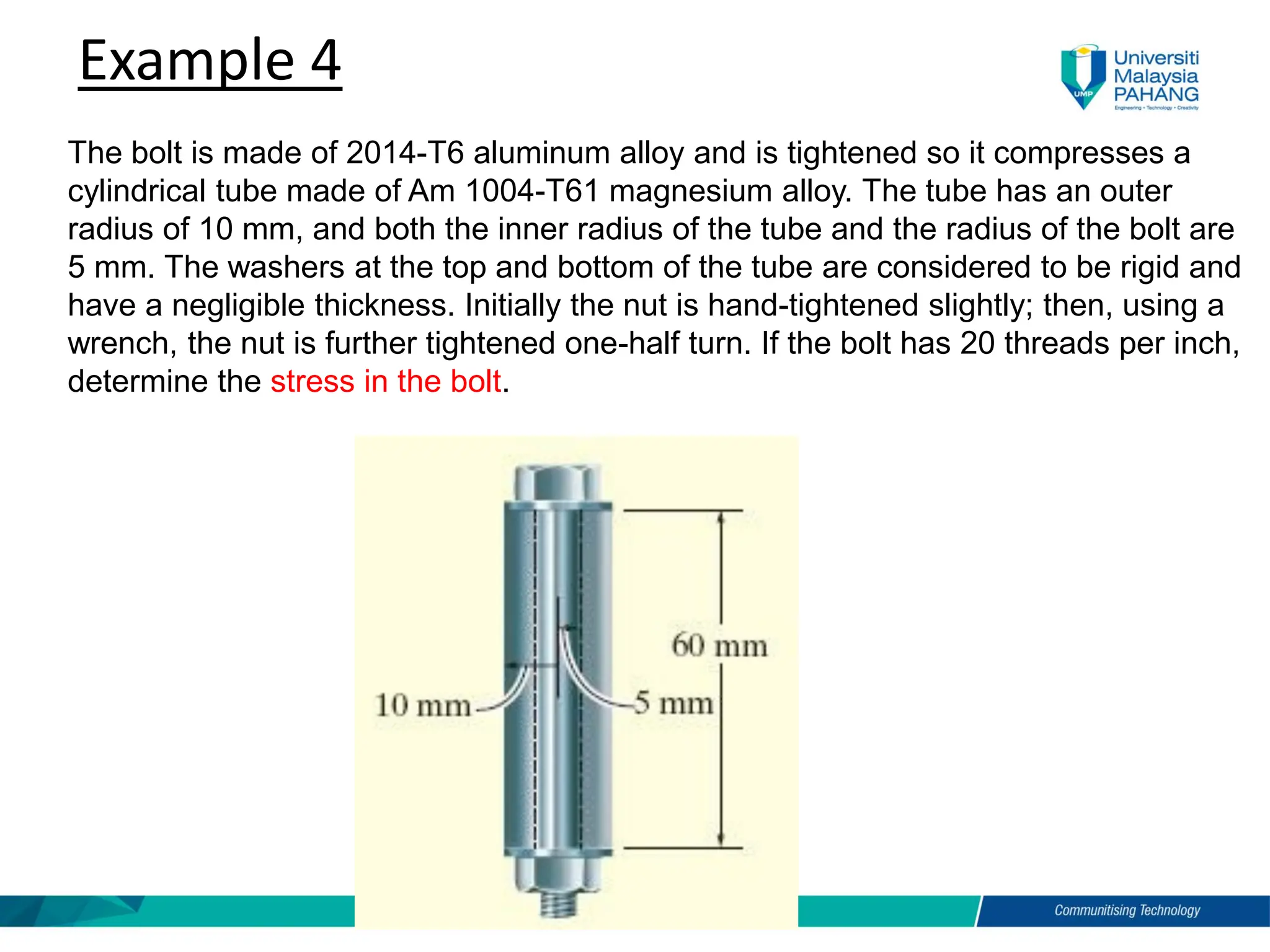

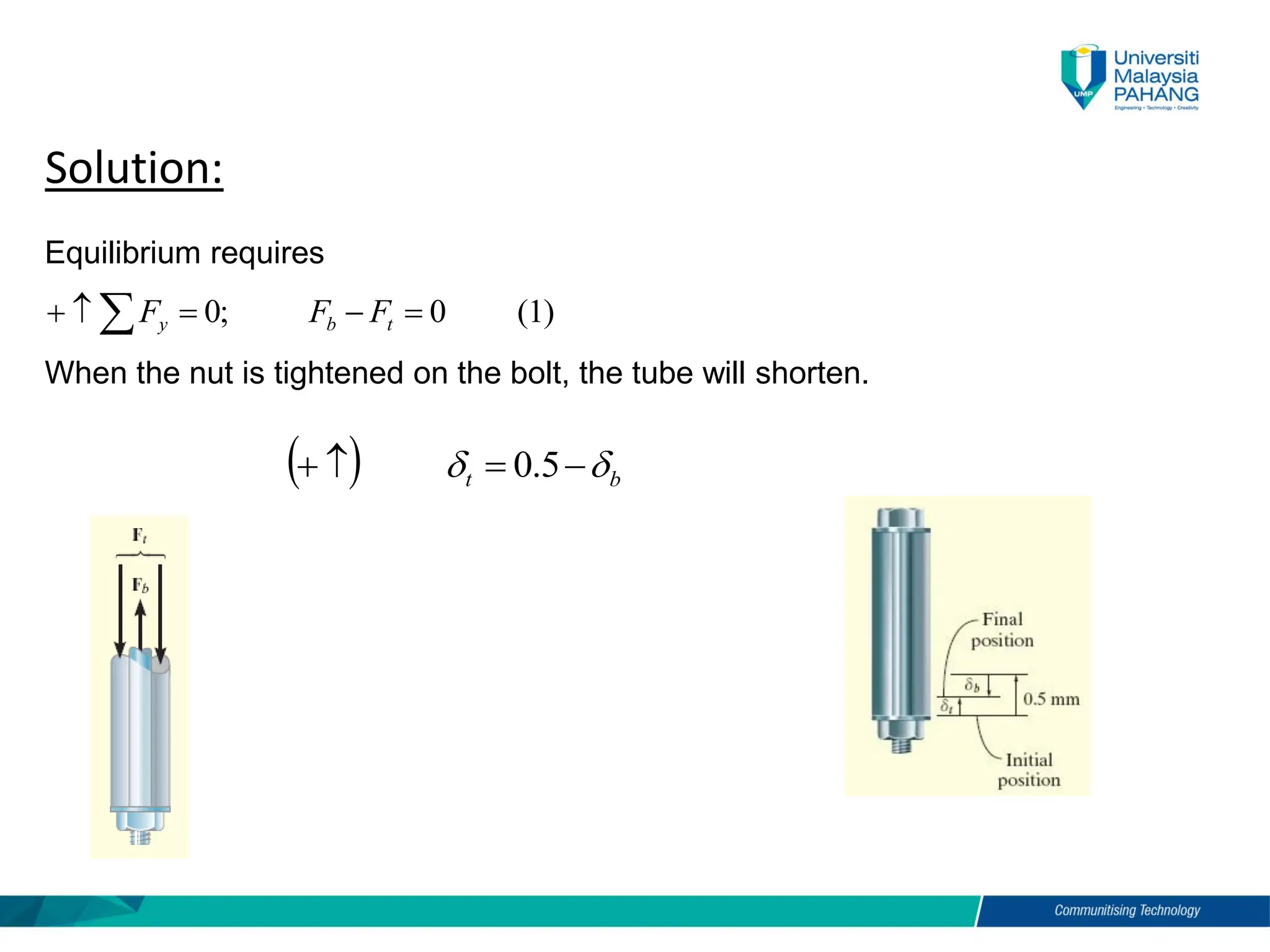

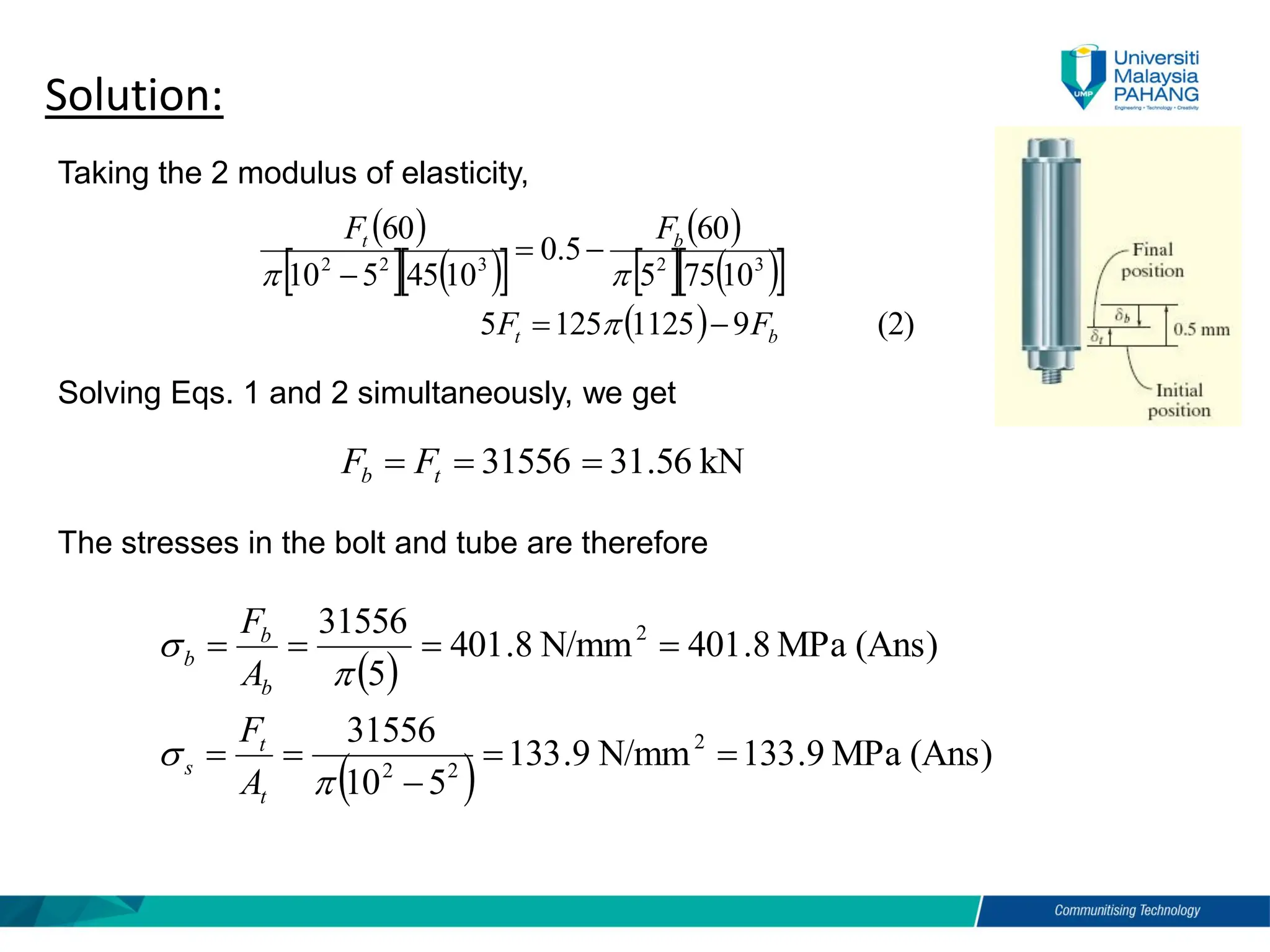

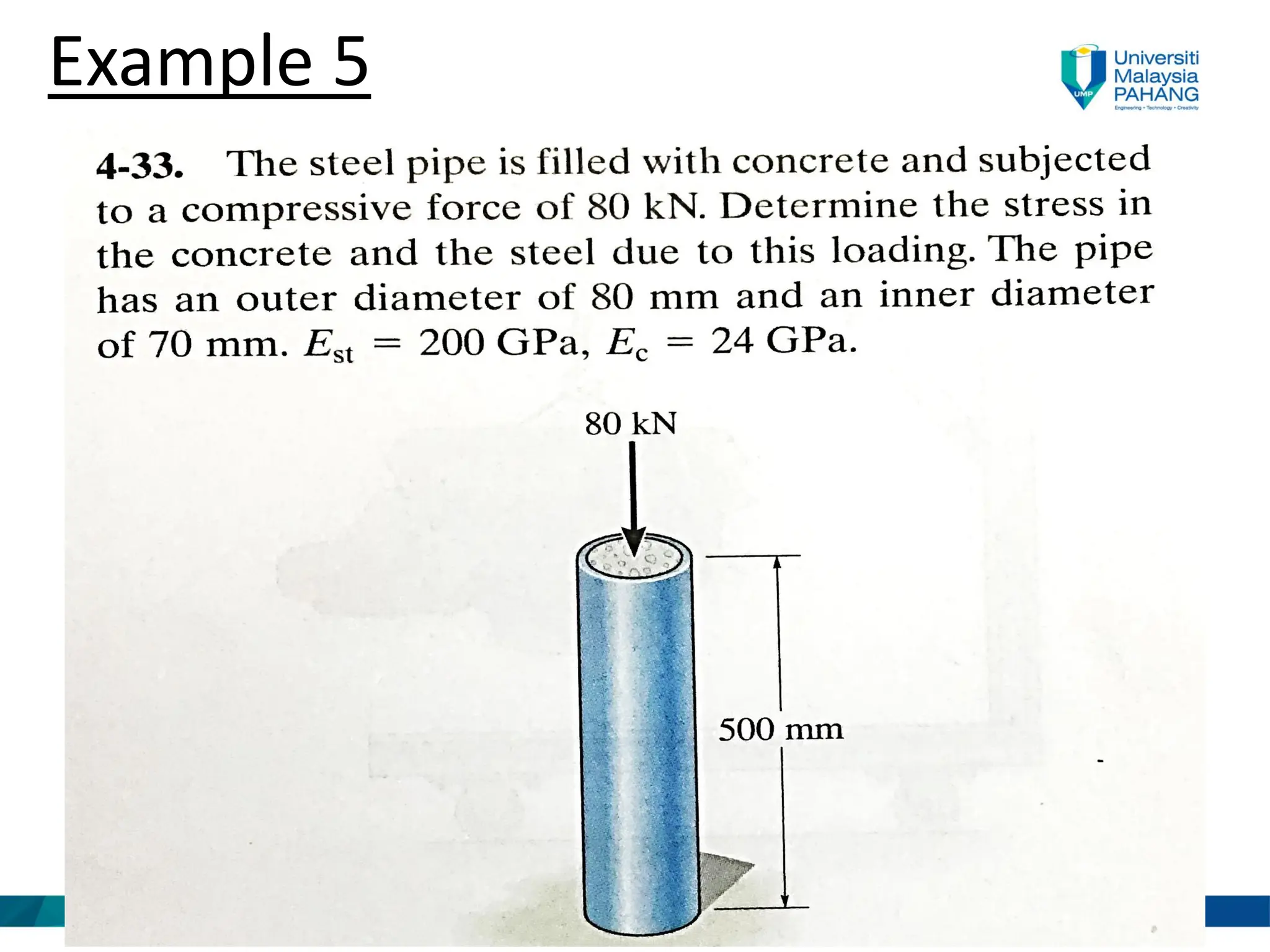

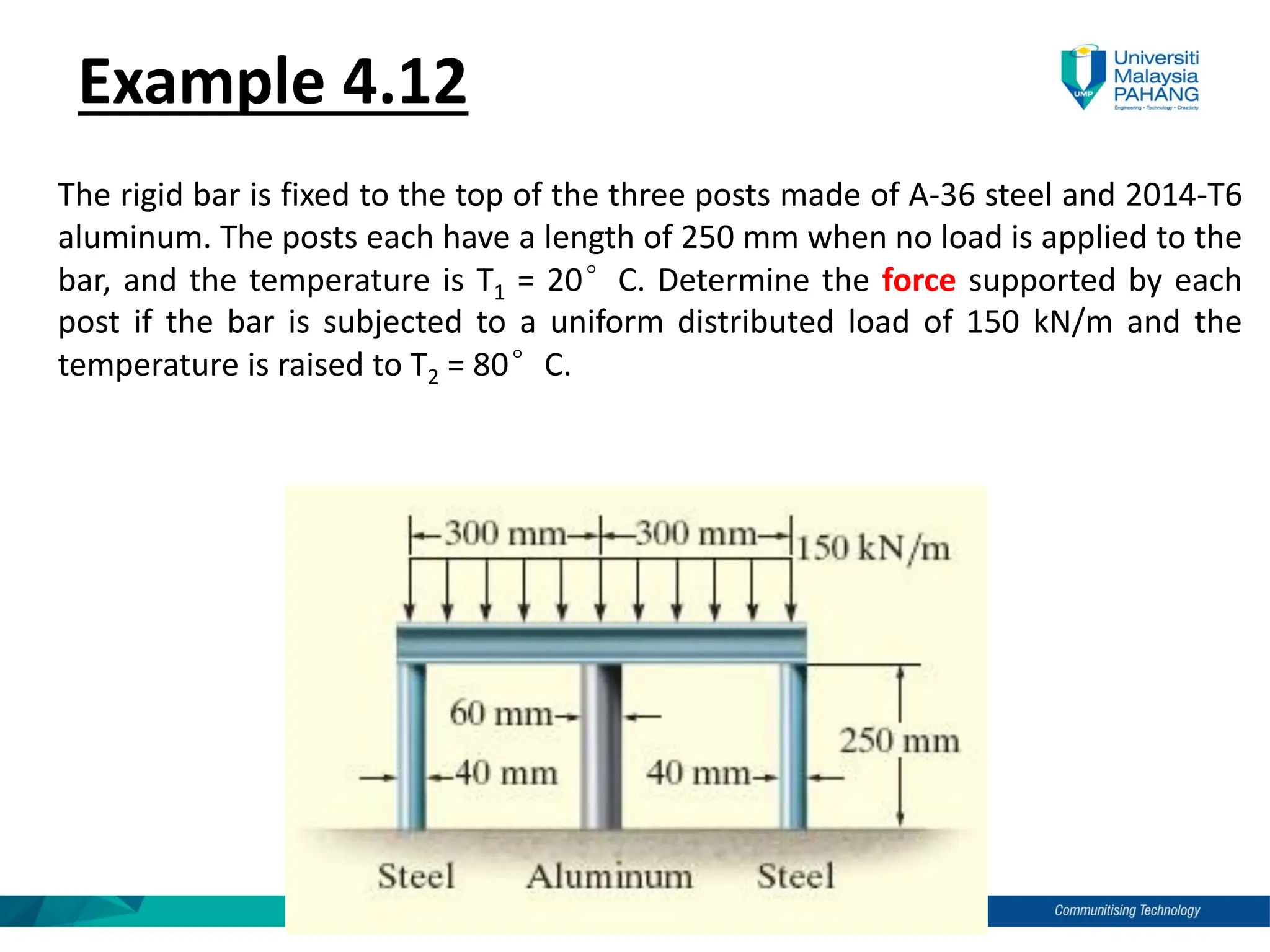

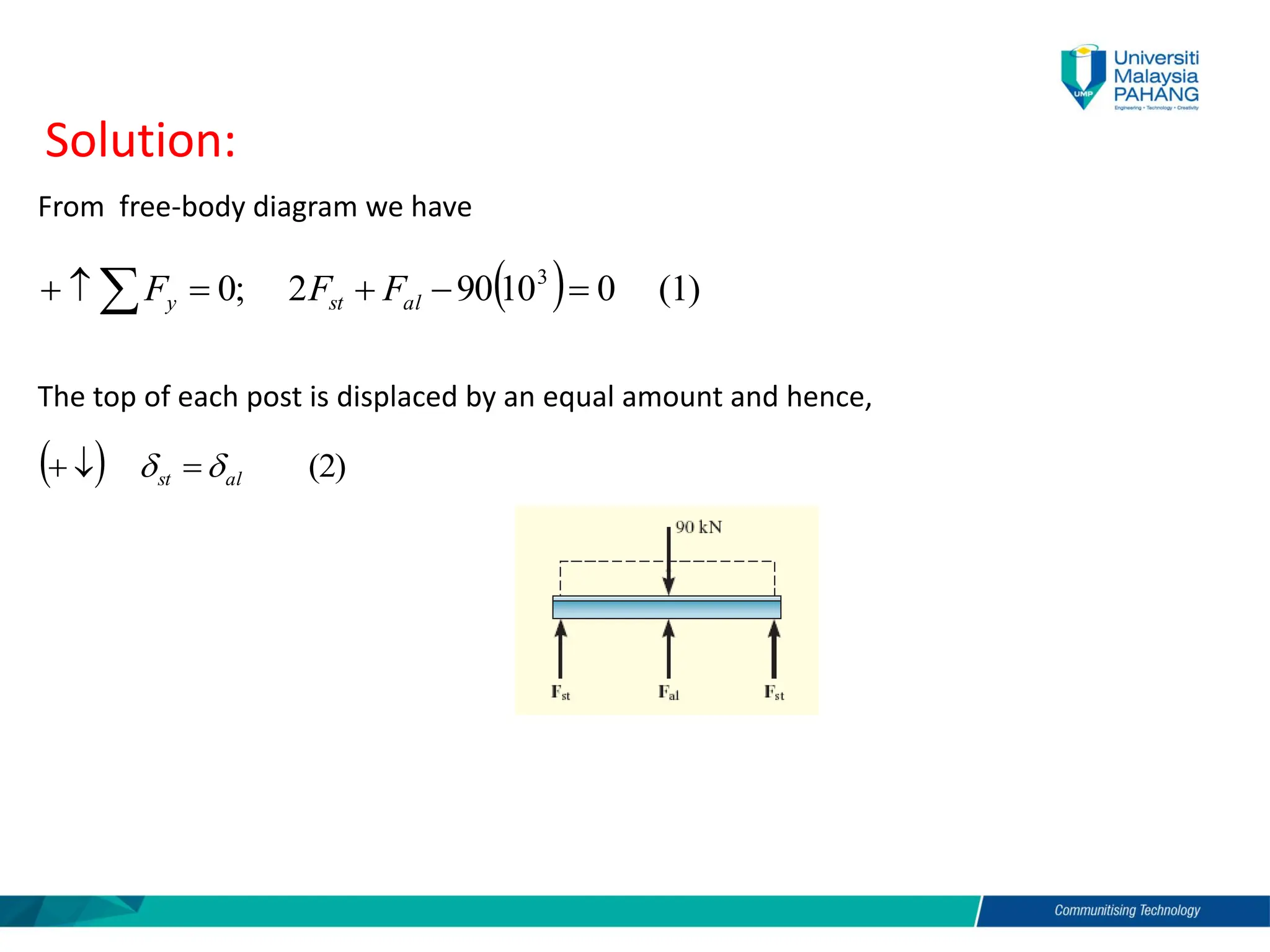

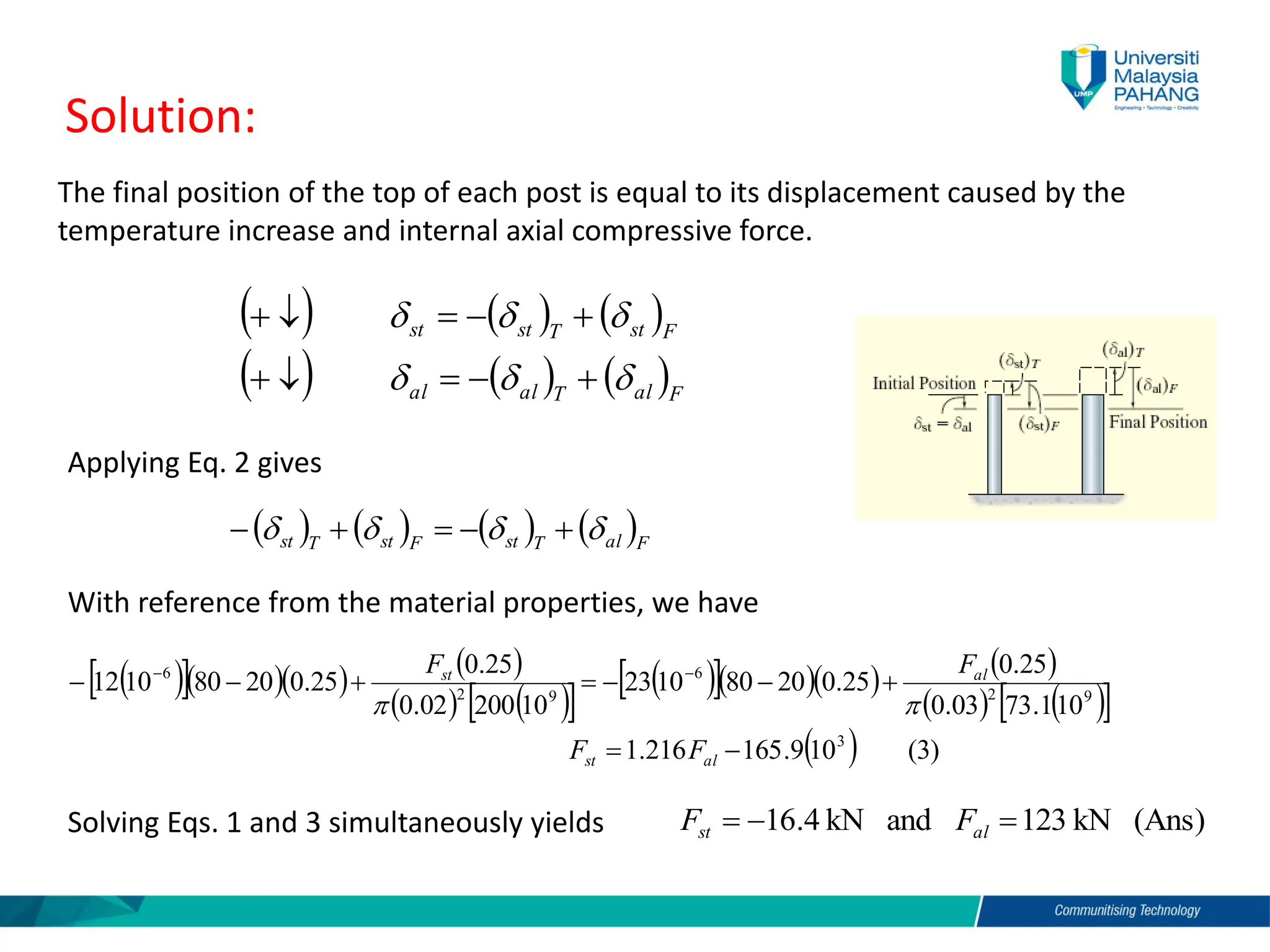

Chapter 4 of the mechanics of materials discusses the effects of axial load on prismatic bars, defining key concepts such as elastic deformation, superposition and Saint-Venant’s principle. It includes methods for calculating deformations under axial load and analyzes statically indeterminate assemblies and temperature effects on materials. Practical examples illustrate the application of these principles in engineering scenarios.