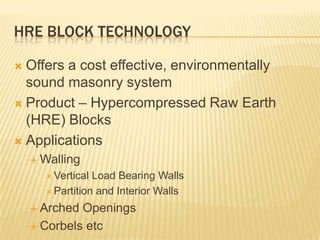

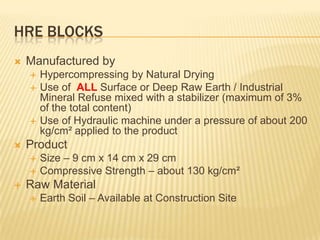

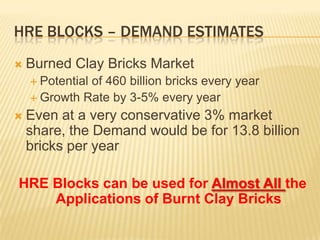

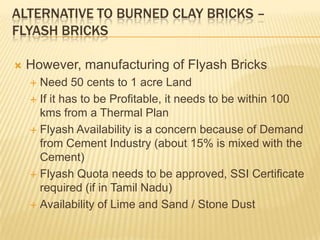

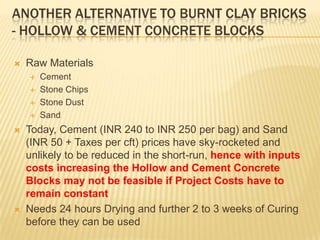

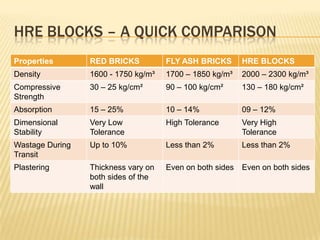

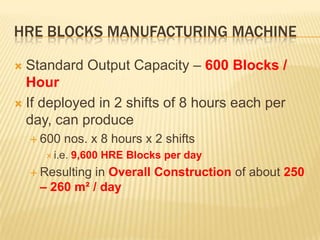

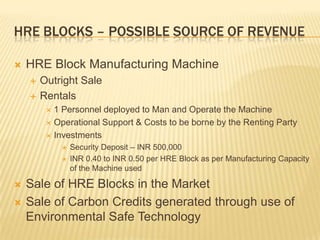

The document describes a new technology called hypercompressed raw earth (HRE) blocks for construction. HRE blocks are an affordable, environmentally friendly alternative to burnt clay bricks. They are made by compressing local earth and have properties like high strength, insulation, and tolerance. A mechanized machine can produce 9,600 blocks per day at low cost using local resources. HRE blocks could capture market share from burnt clay bricks and provide housing solutions. The document proposes discussing the financial feasibility of a project to manufacture and sell HRE blocks using the new machine.