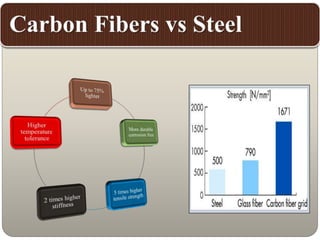

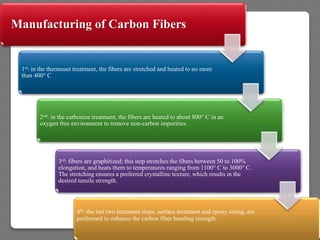

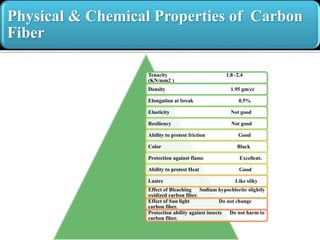

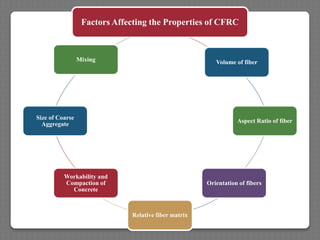

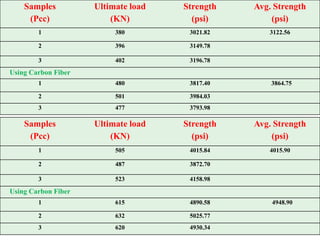

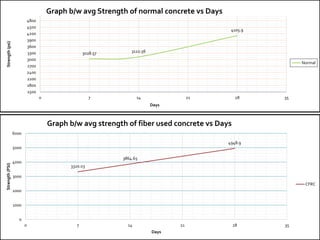

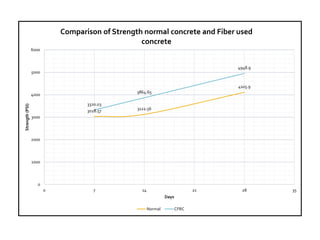

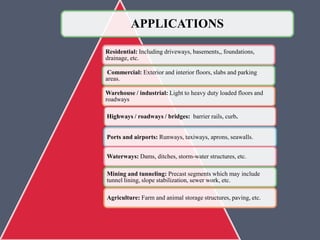

Carbocrete is a type of concrete reinforced with carbon fibers, also known as carbon fiber reinforced concrete (CFRC). It combines high-strength concrete with carbon fibers to produce a lightweight, highly stress-resistant composite material. Testing showed that CFRC has higher strength than steel reinforced concrete, with only a quarter of the weight. The carbon fibers are manufactured through a process of stretching, heating, and graphitizing to produce fibers with high tensile strength. Samples of CFRC showed significantly higher strength compared to ordinary concrete when tested over 28 days, with strengths increasing as the fibers were added. CFRC has many potential applications in construction due to its high strength and lightweight properties.