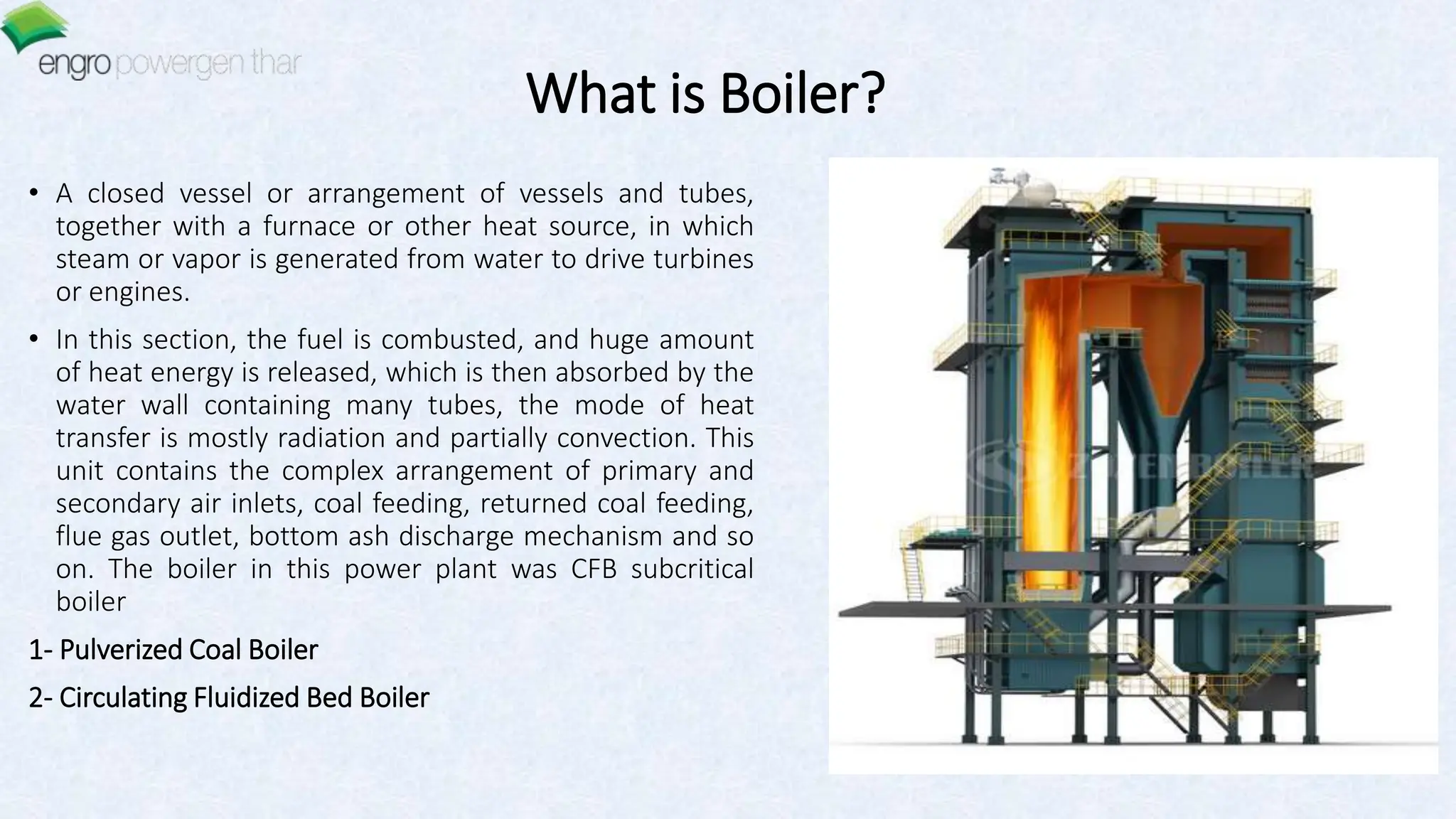

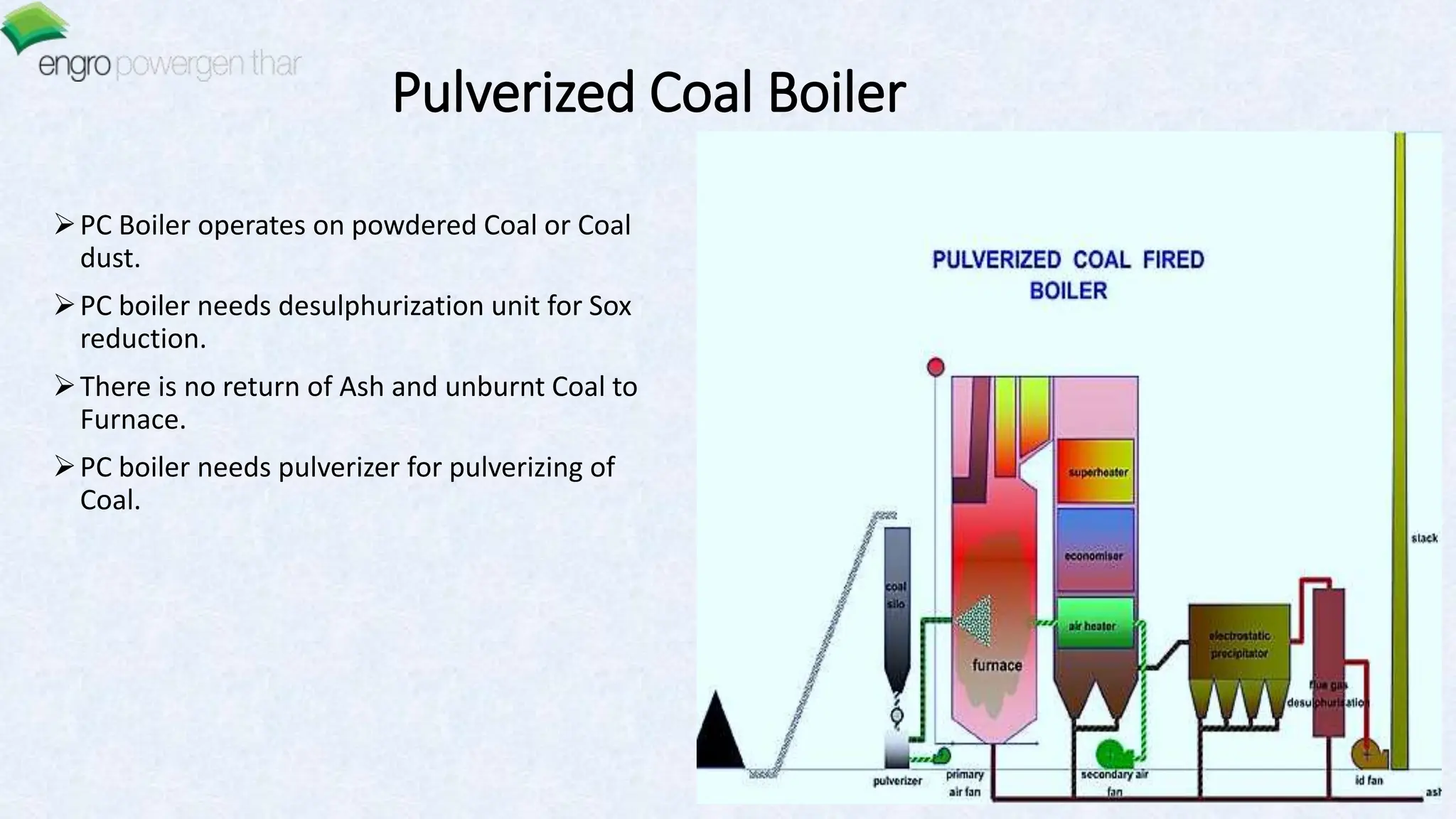

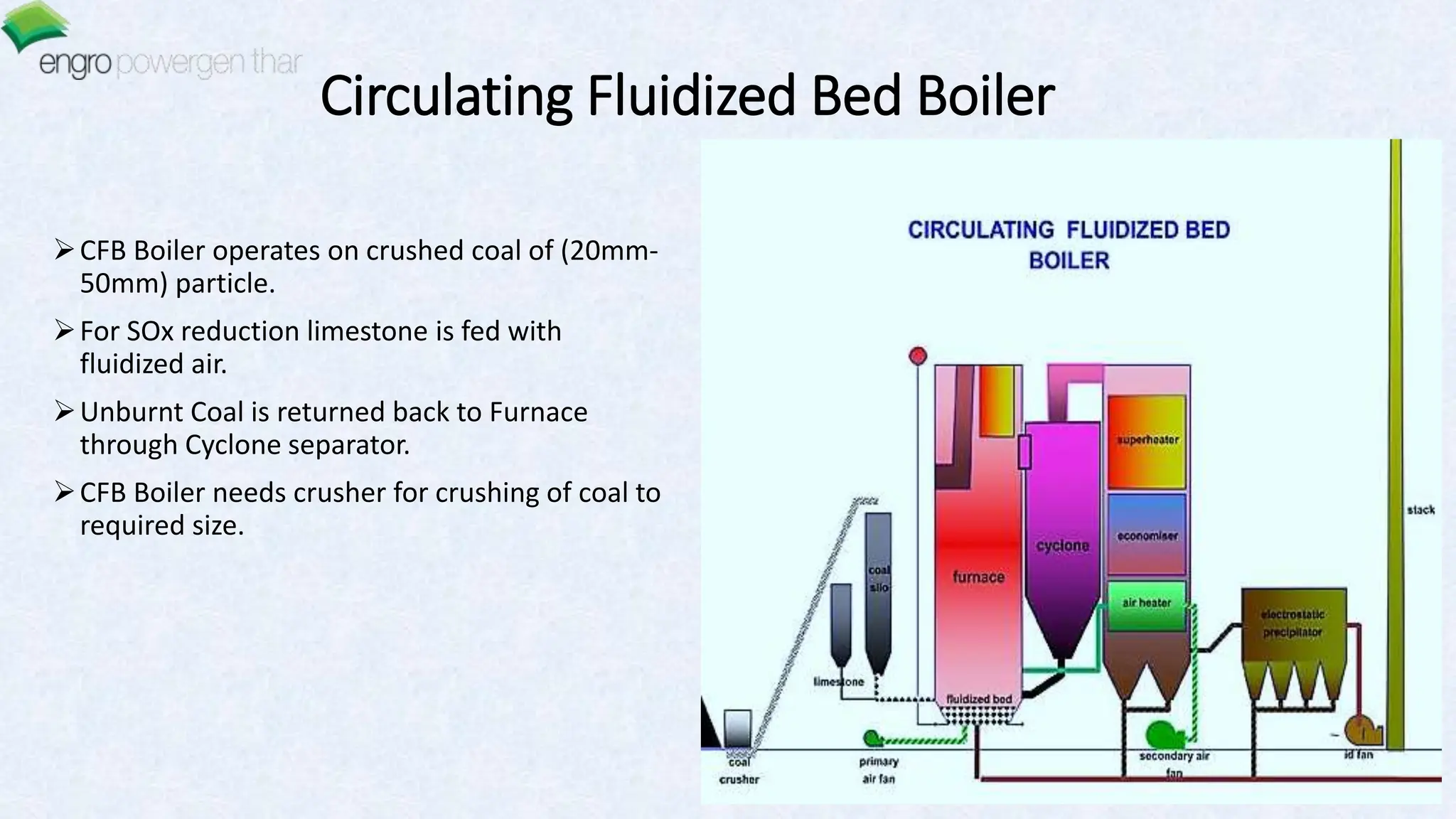

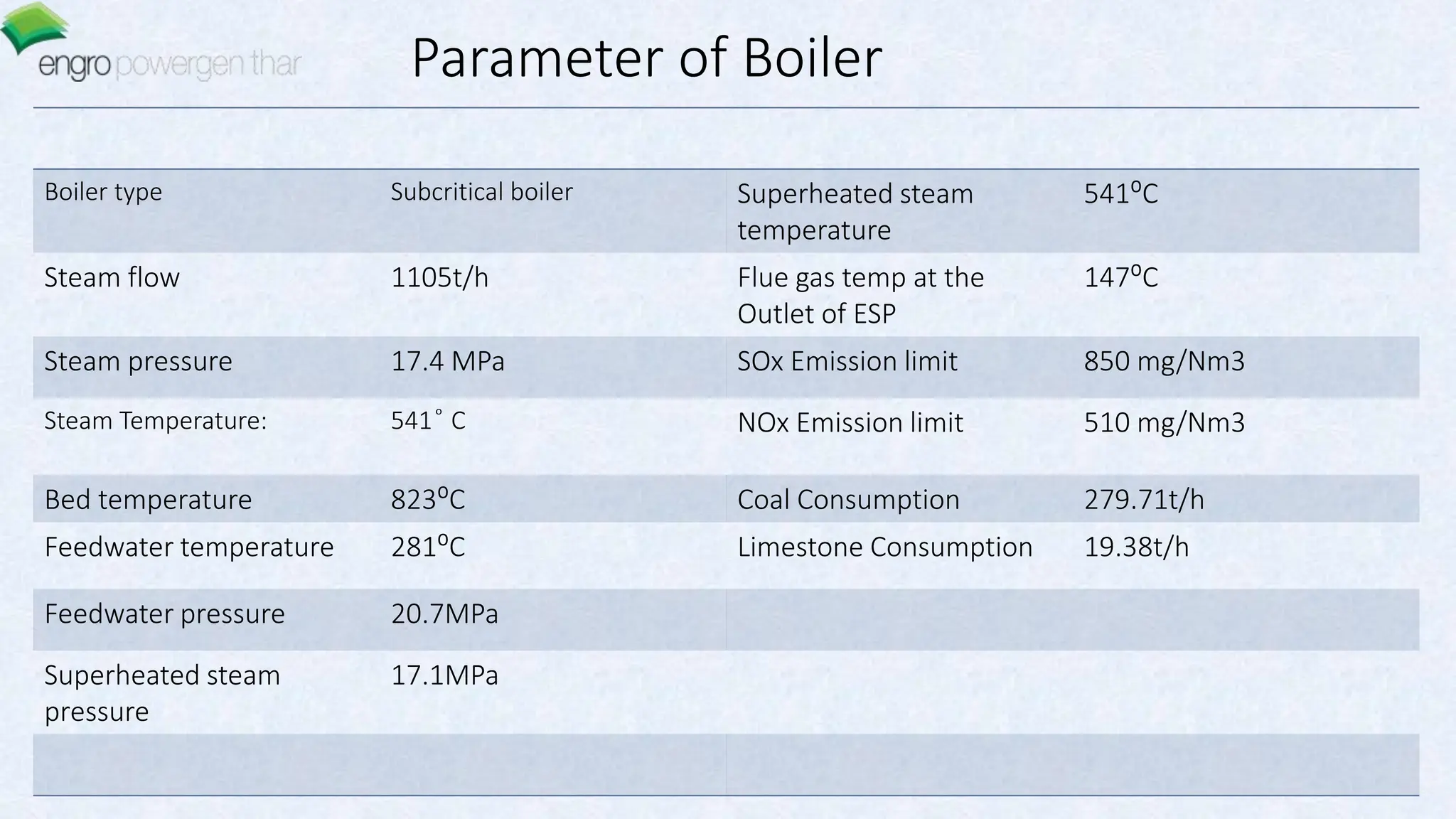

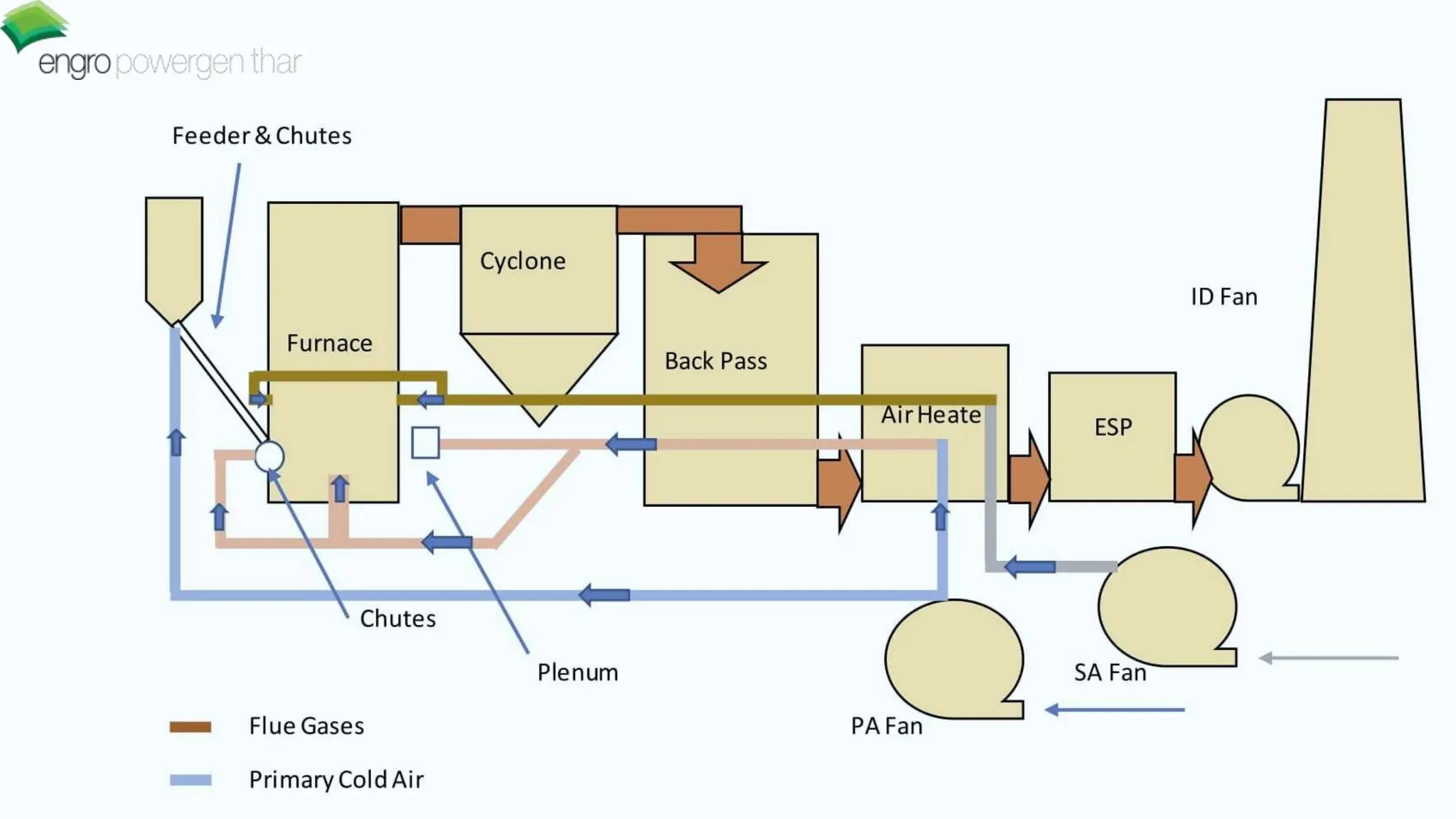

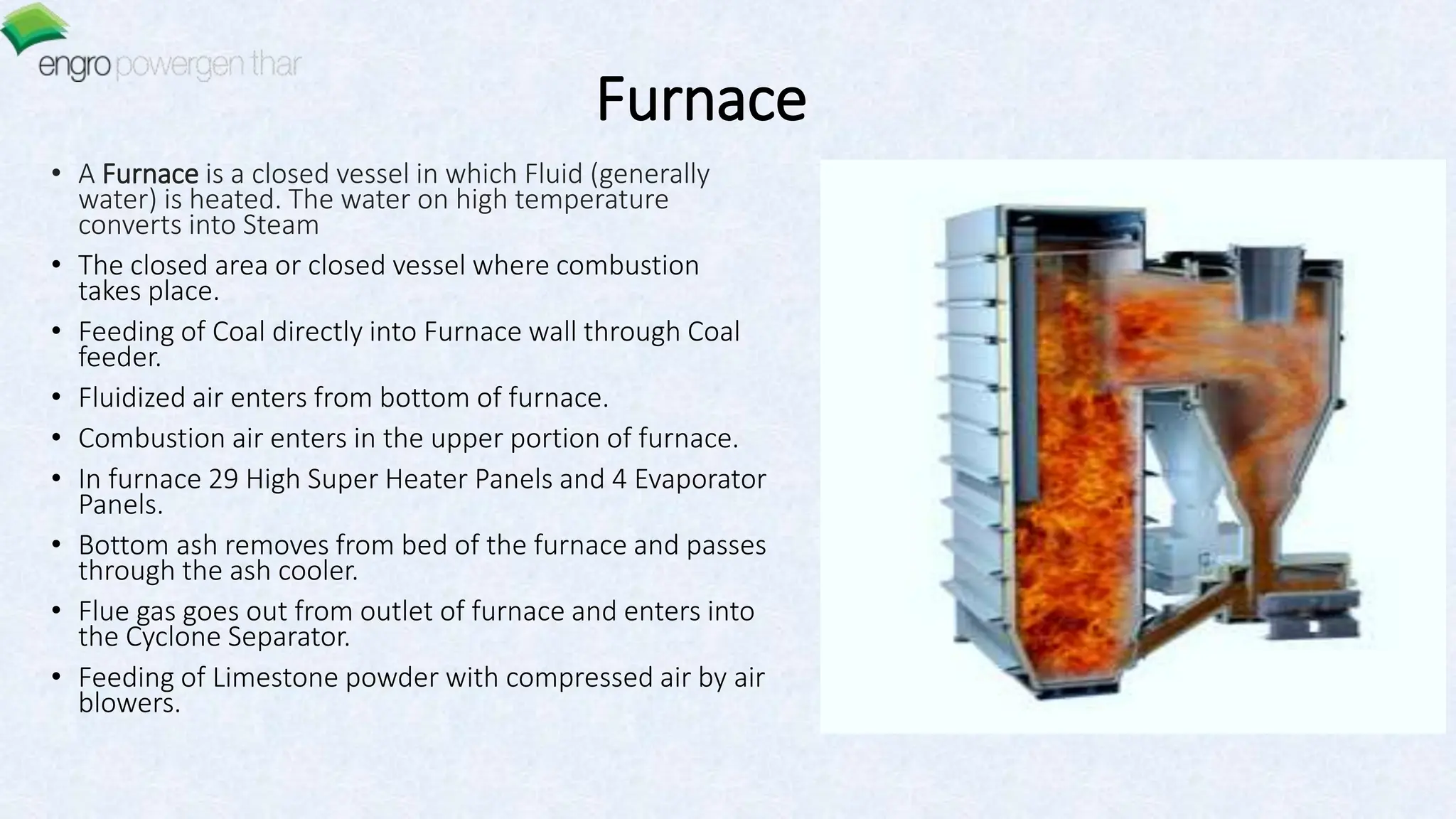

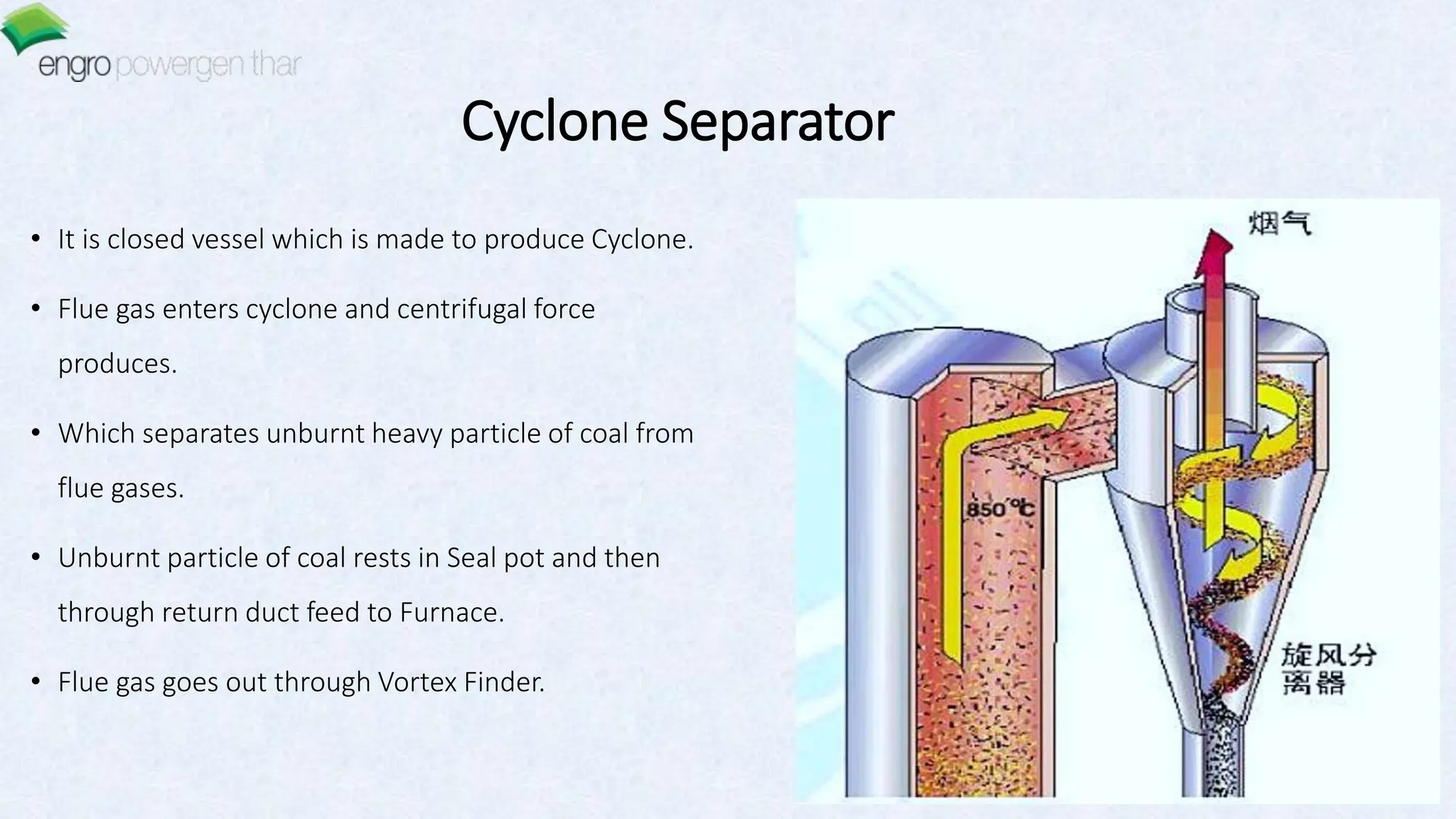

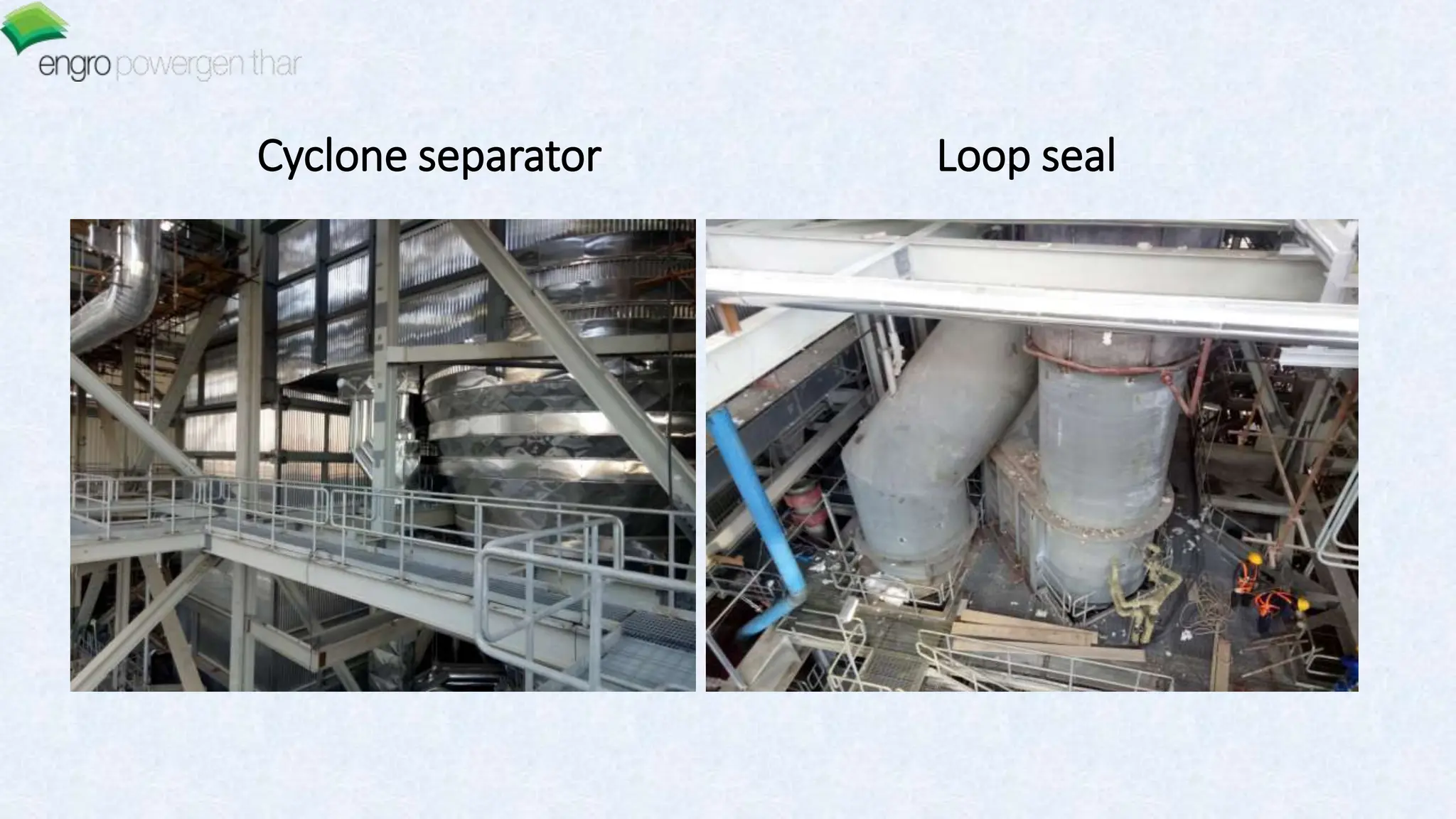

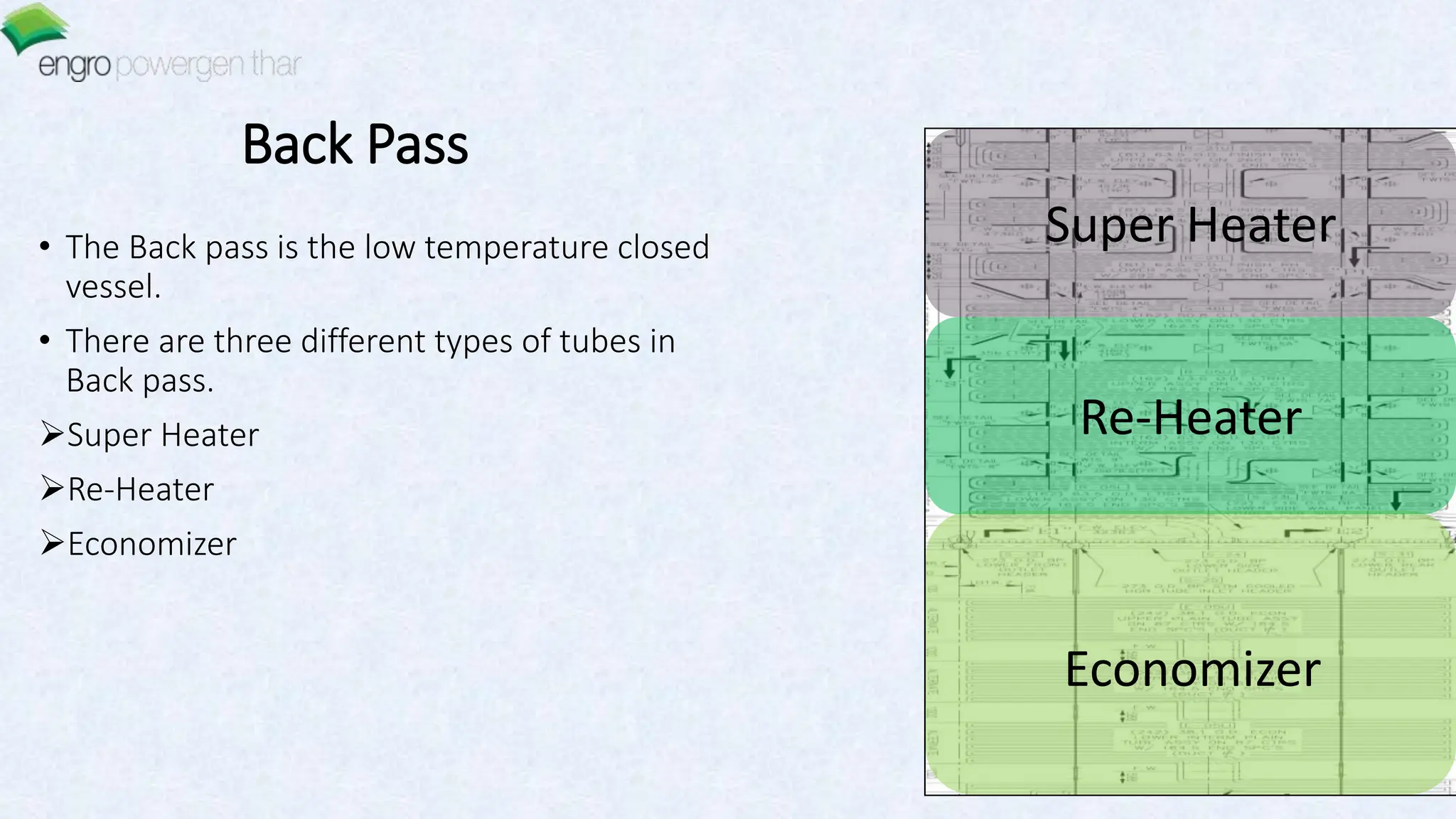

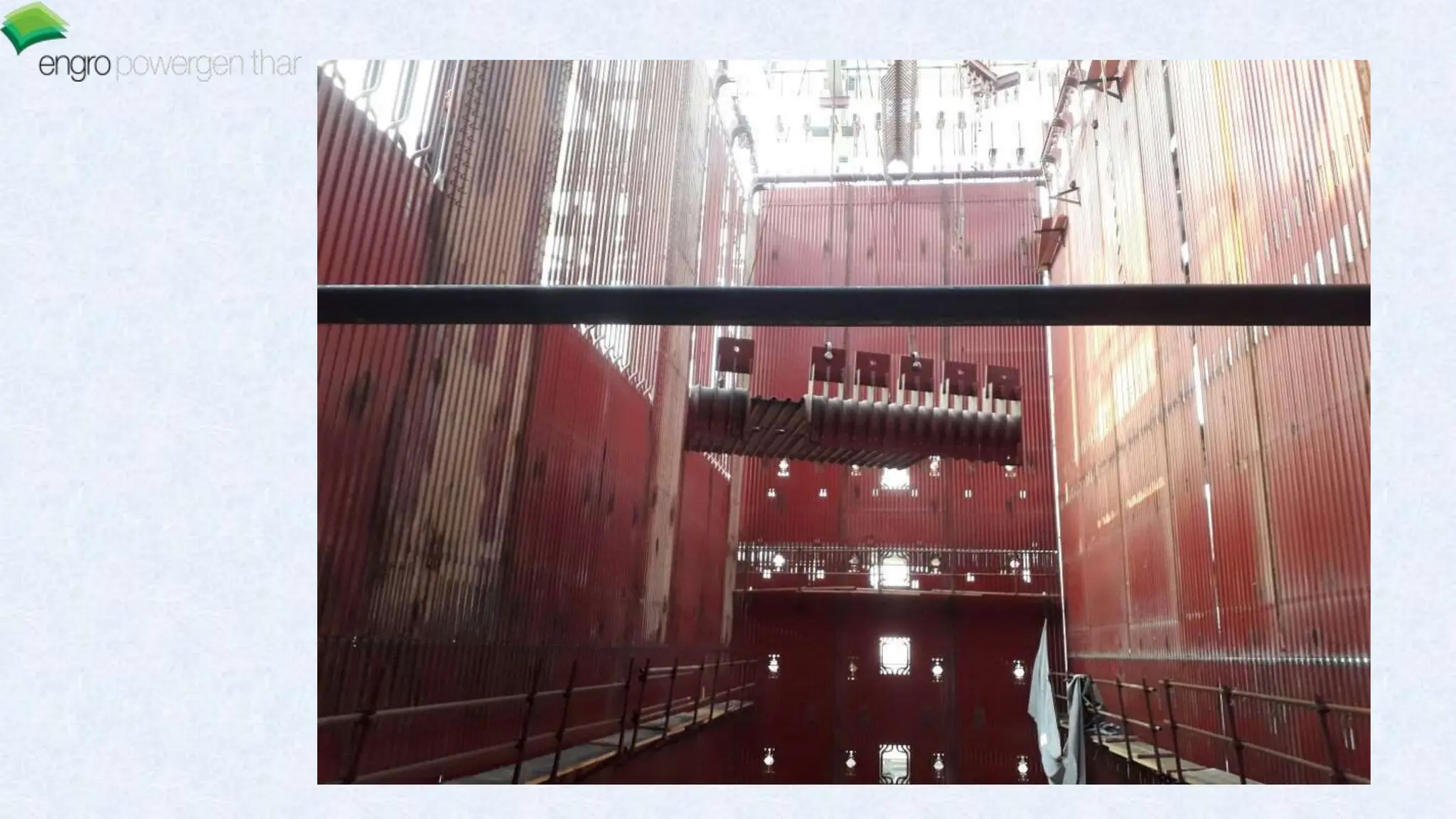

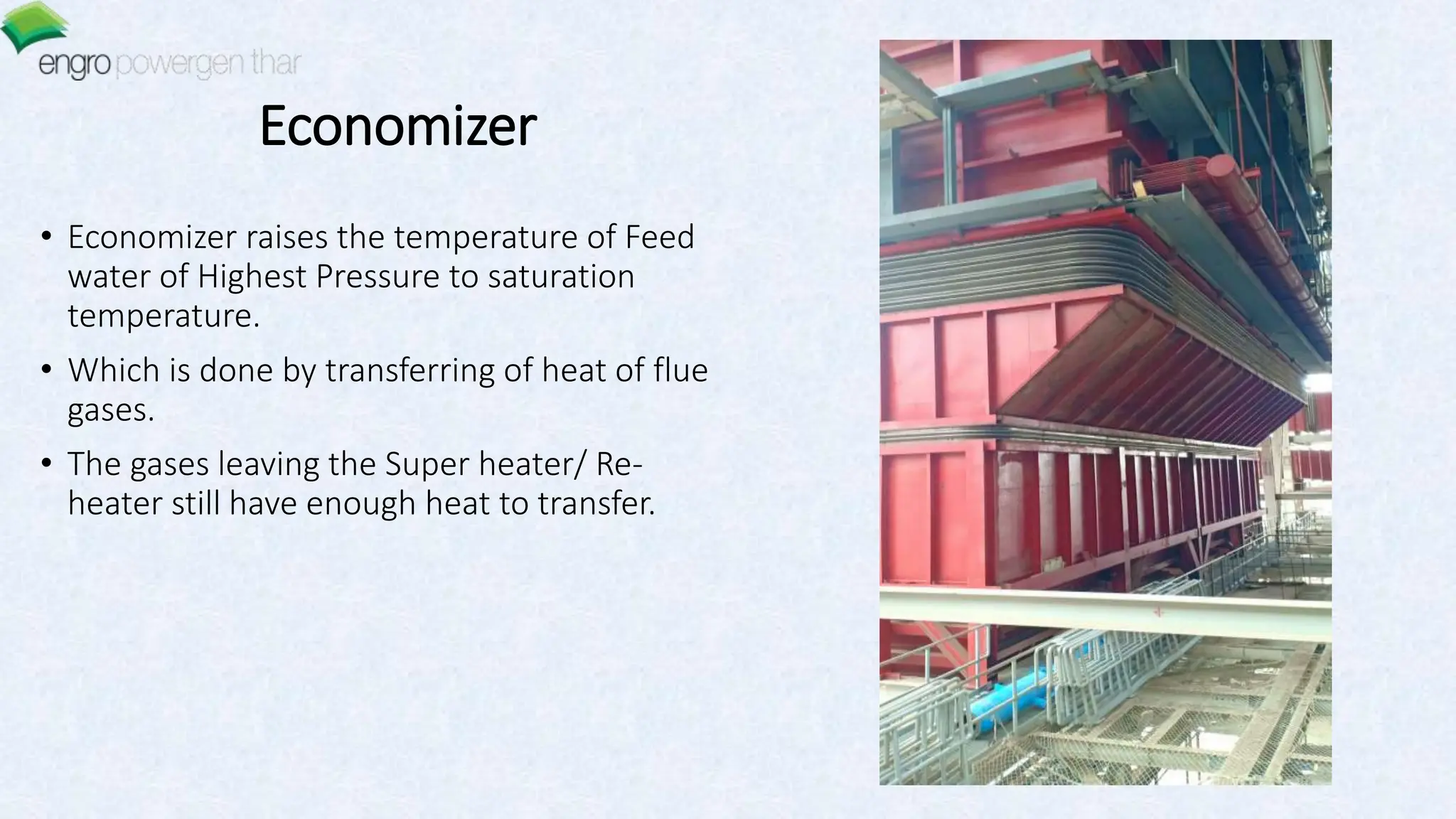

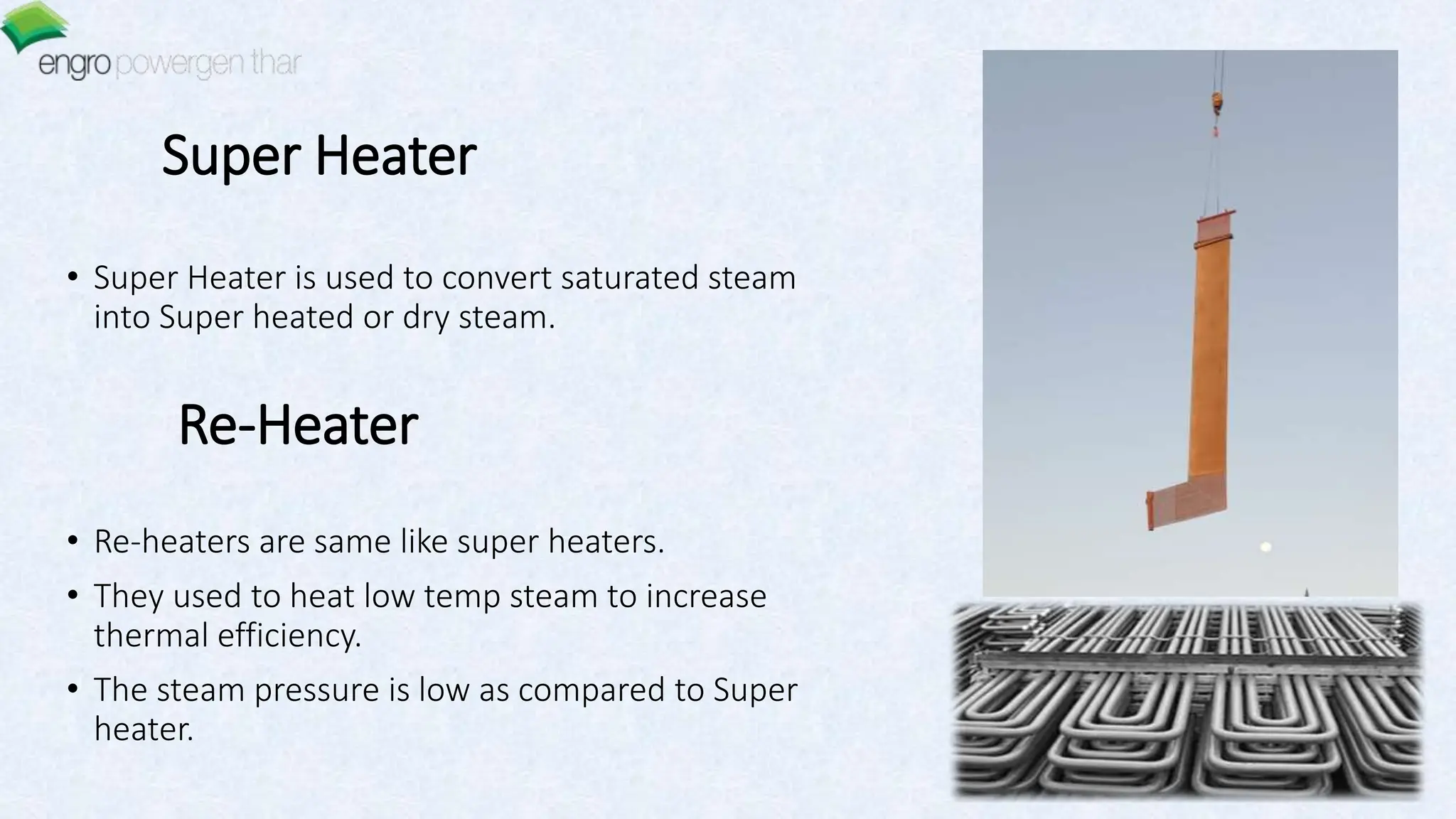

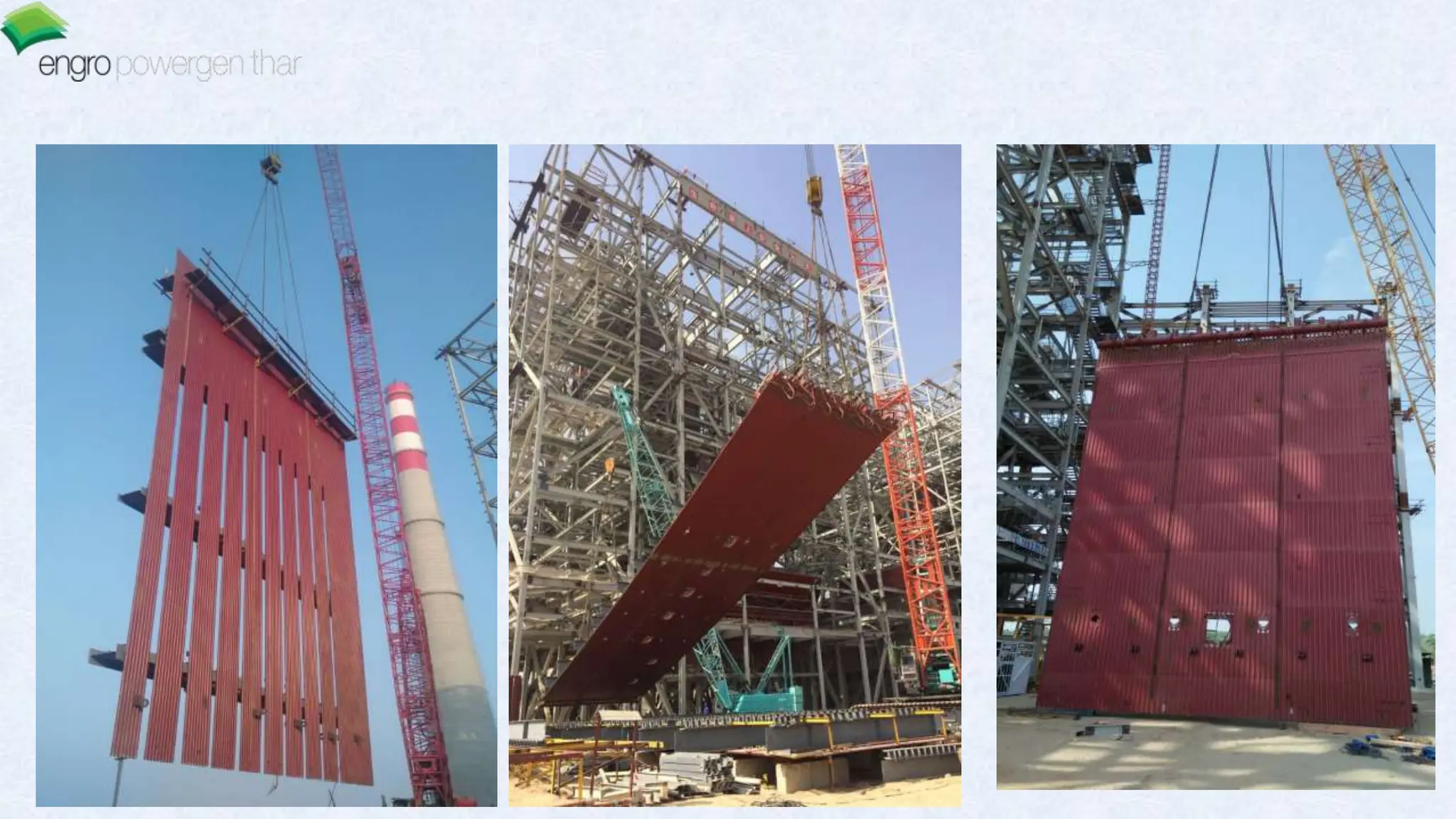

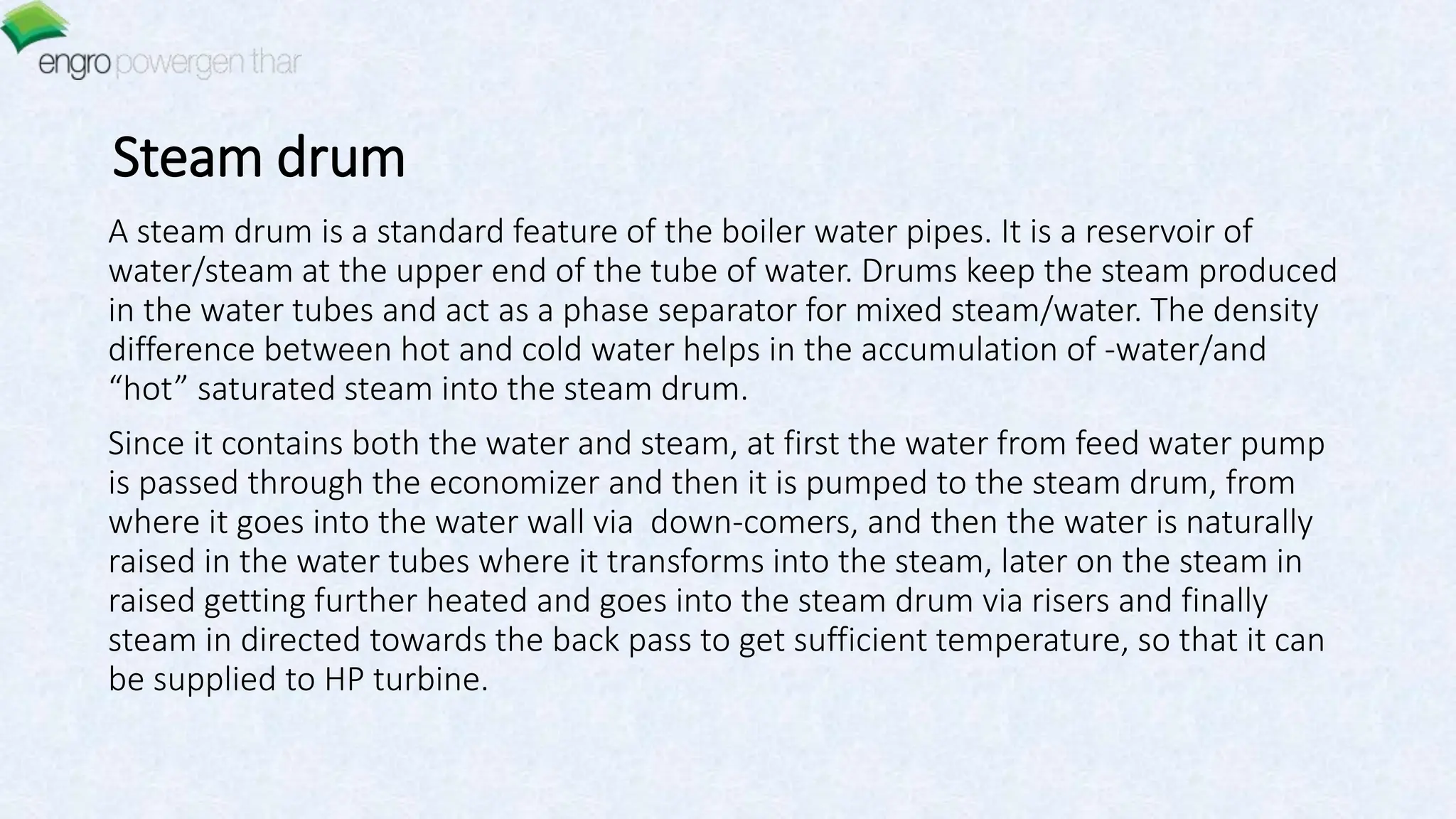

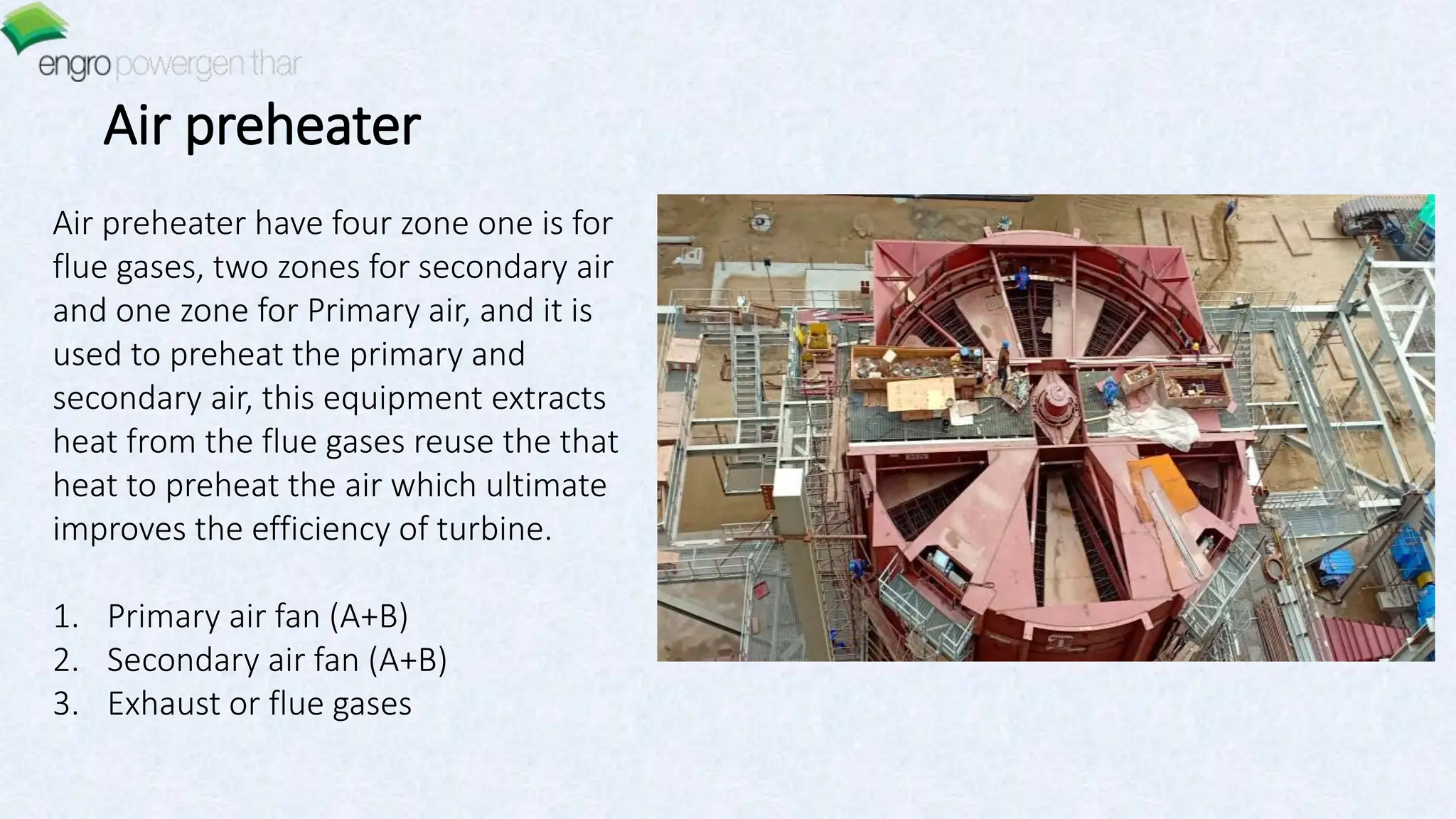

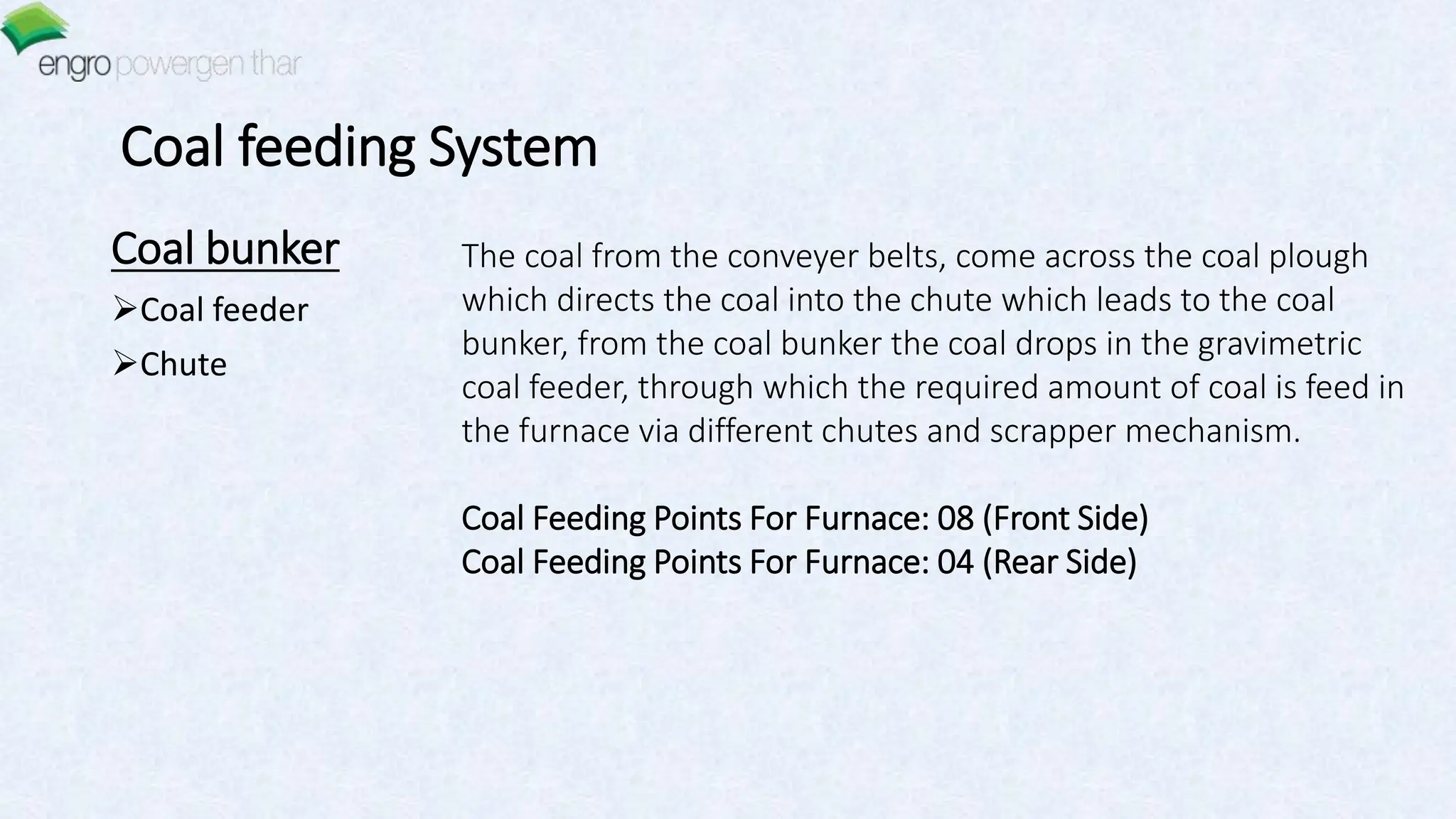

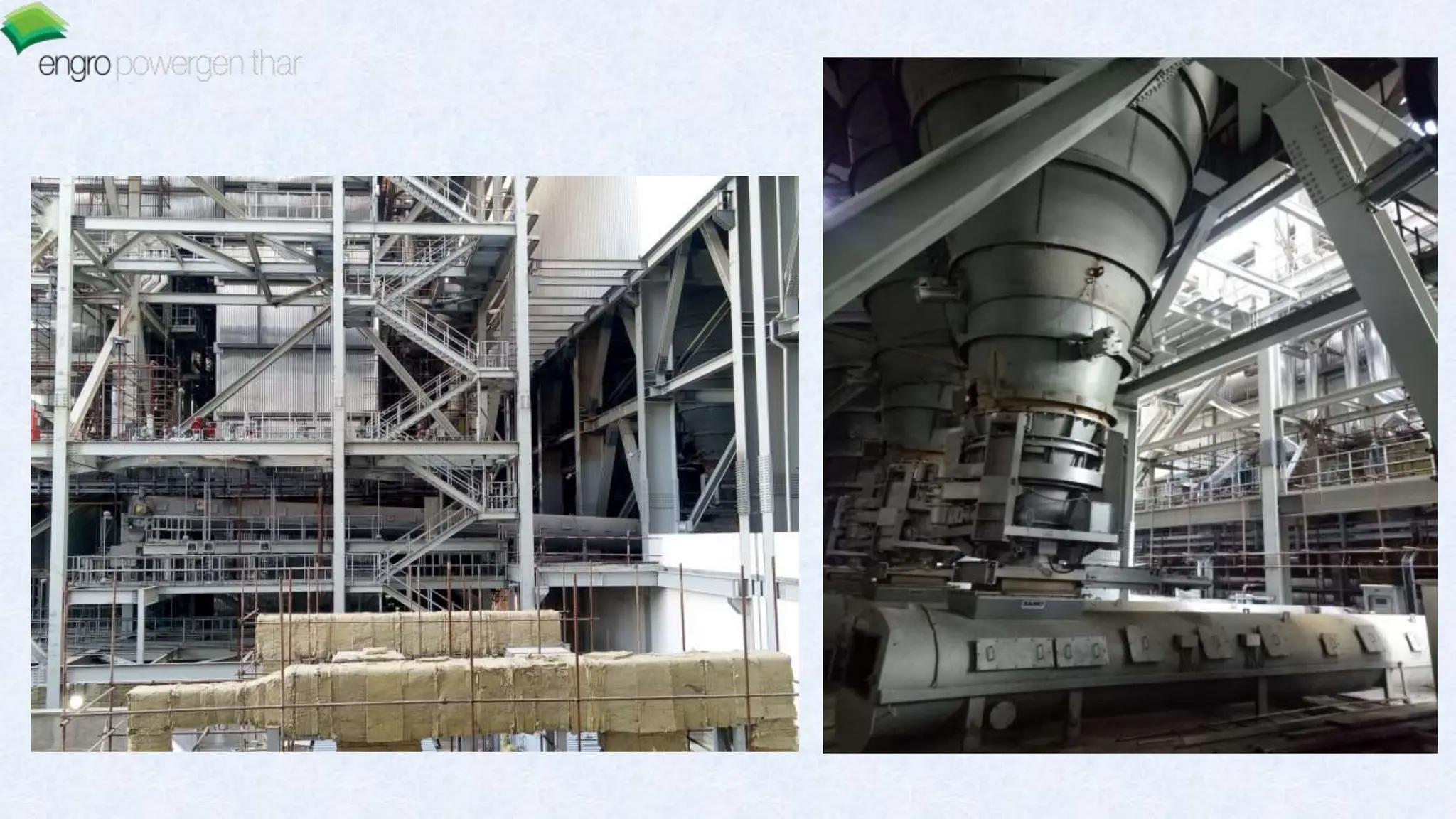

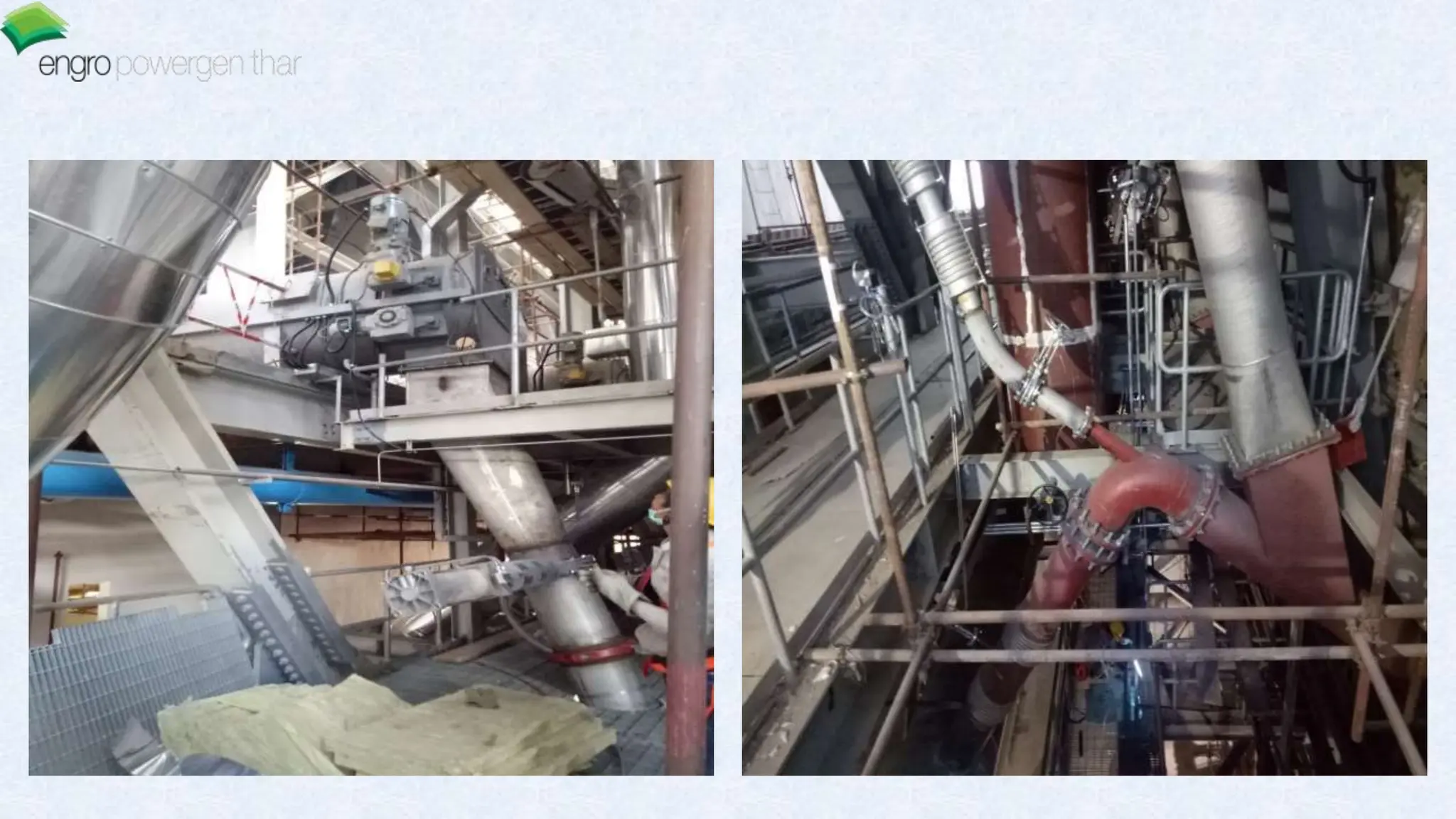

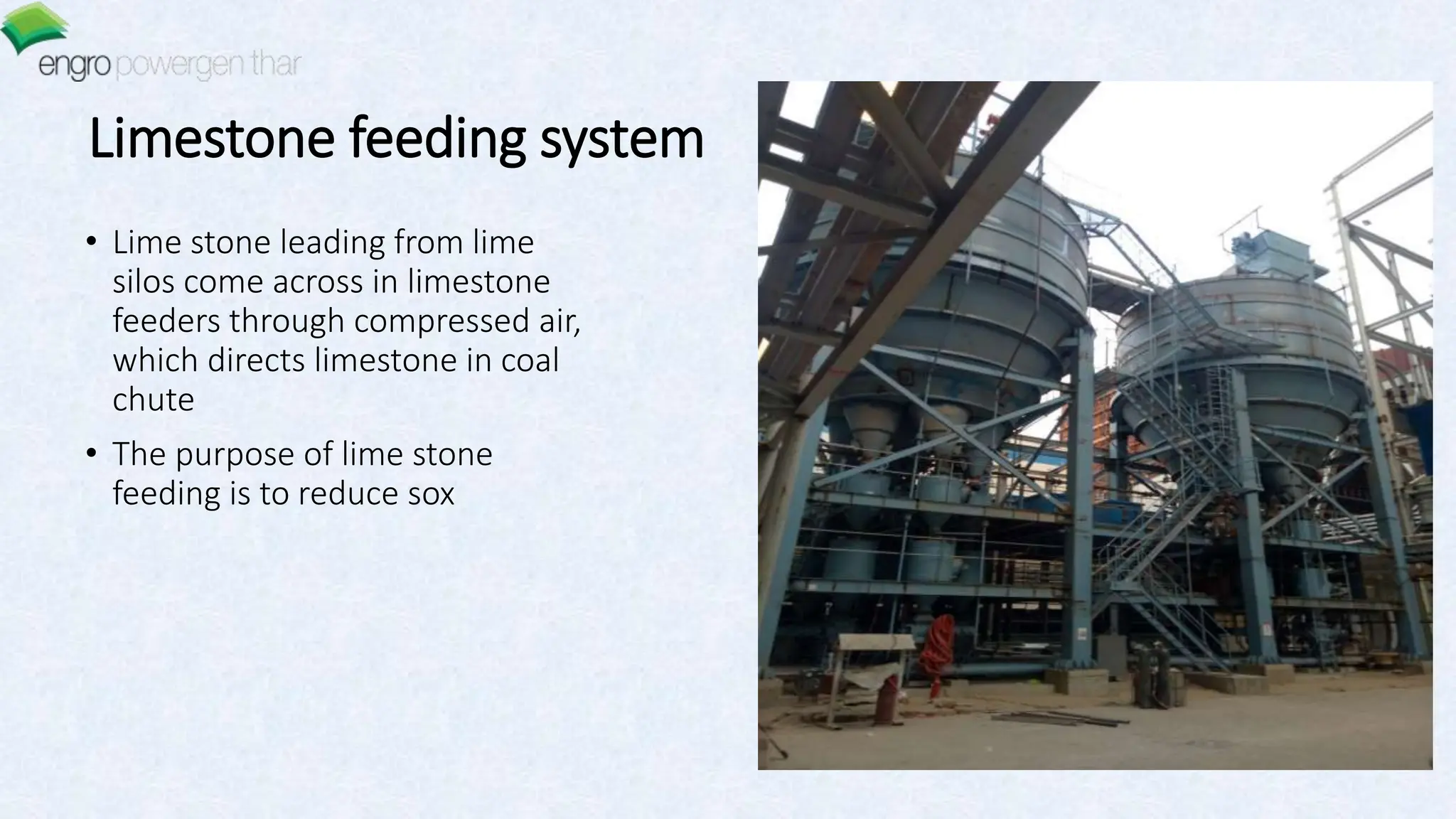

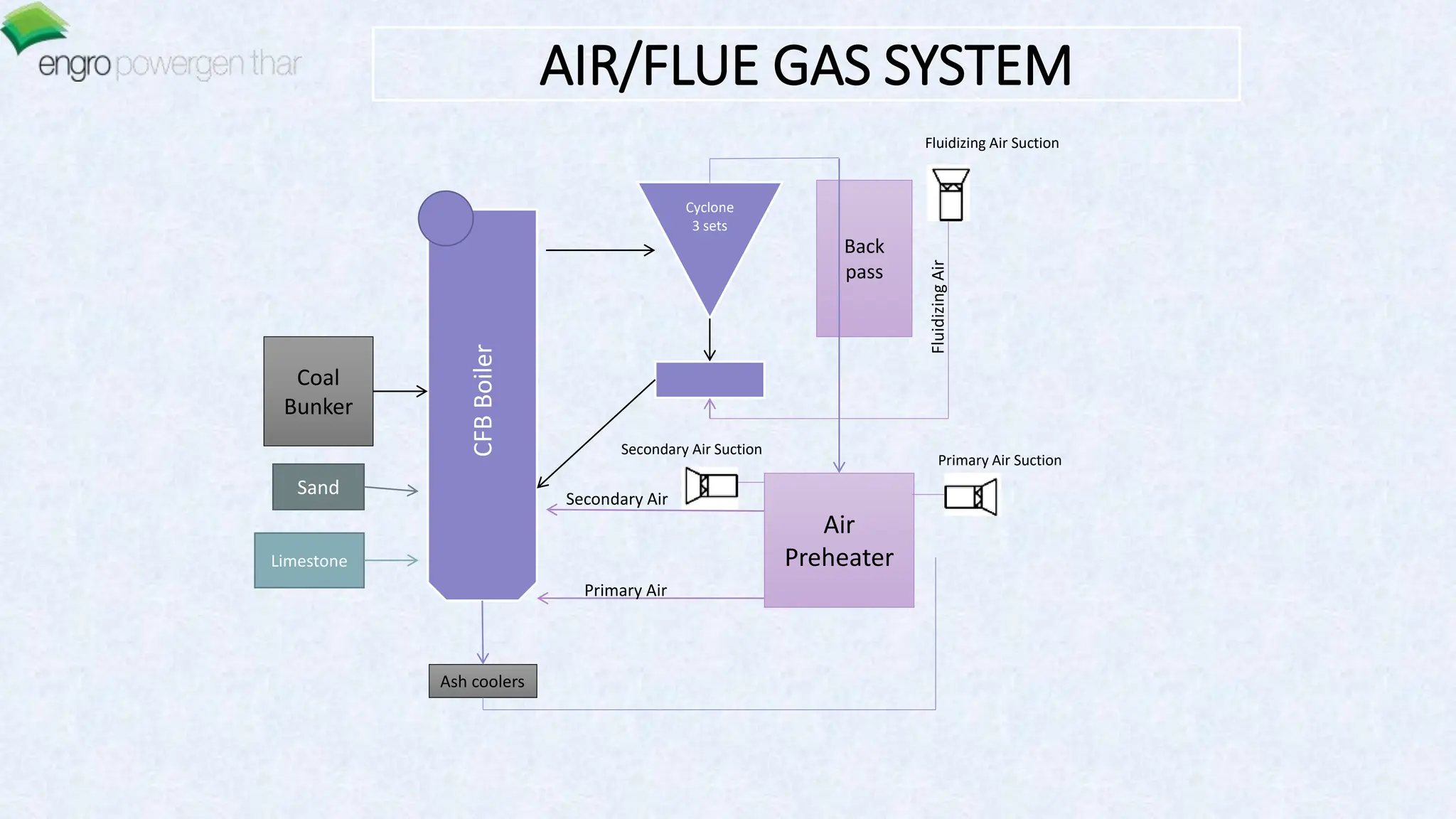

The document describes the key components and operation of a circulating fluidized bed (CFB) boiler. The CFB boiler combusts crushed coal between 20-50mm in size using fluidized air. Unburnt coal is returned to the furnace through a cyclone separator. The main components are the furnace, cyclone separator, back pass, and air preheater. In the furnace, coal is combusted and limestone is added to reduce SOx emissions. The cyclone separator separates unburnt particles from flue gas. Heat from flue gas is transferred in the back pass to produce steam. The air preheater improves efficiency by preheating combustion air.