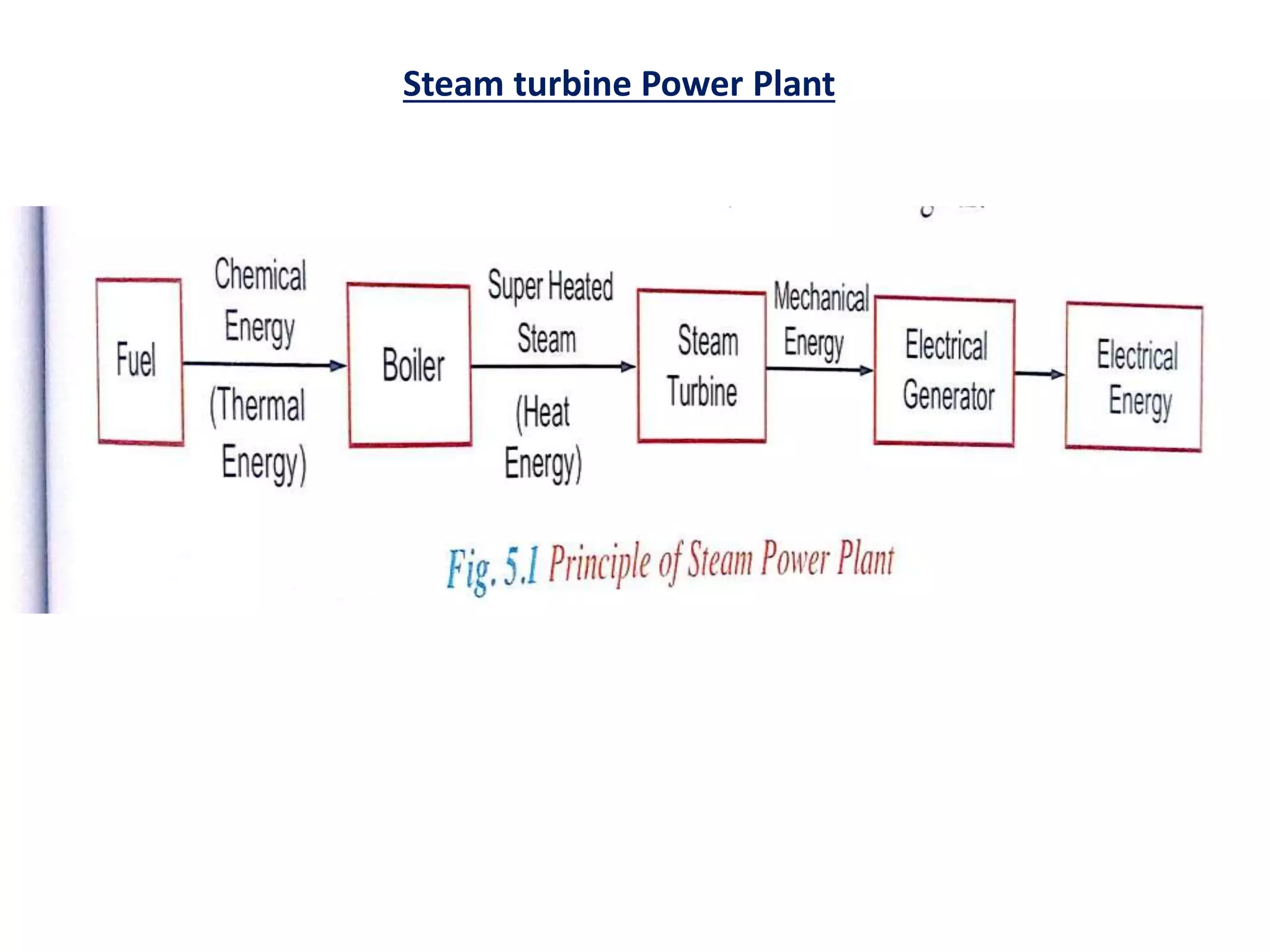

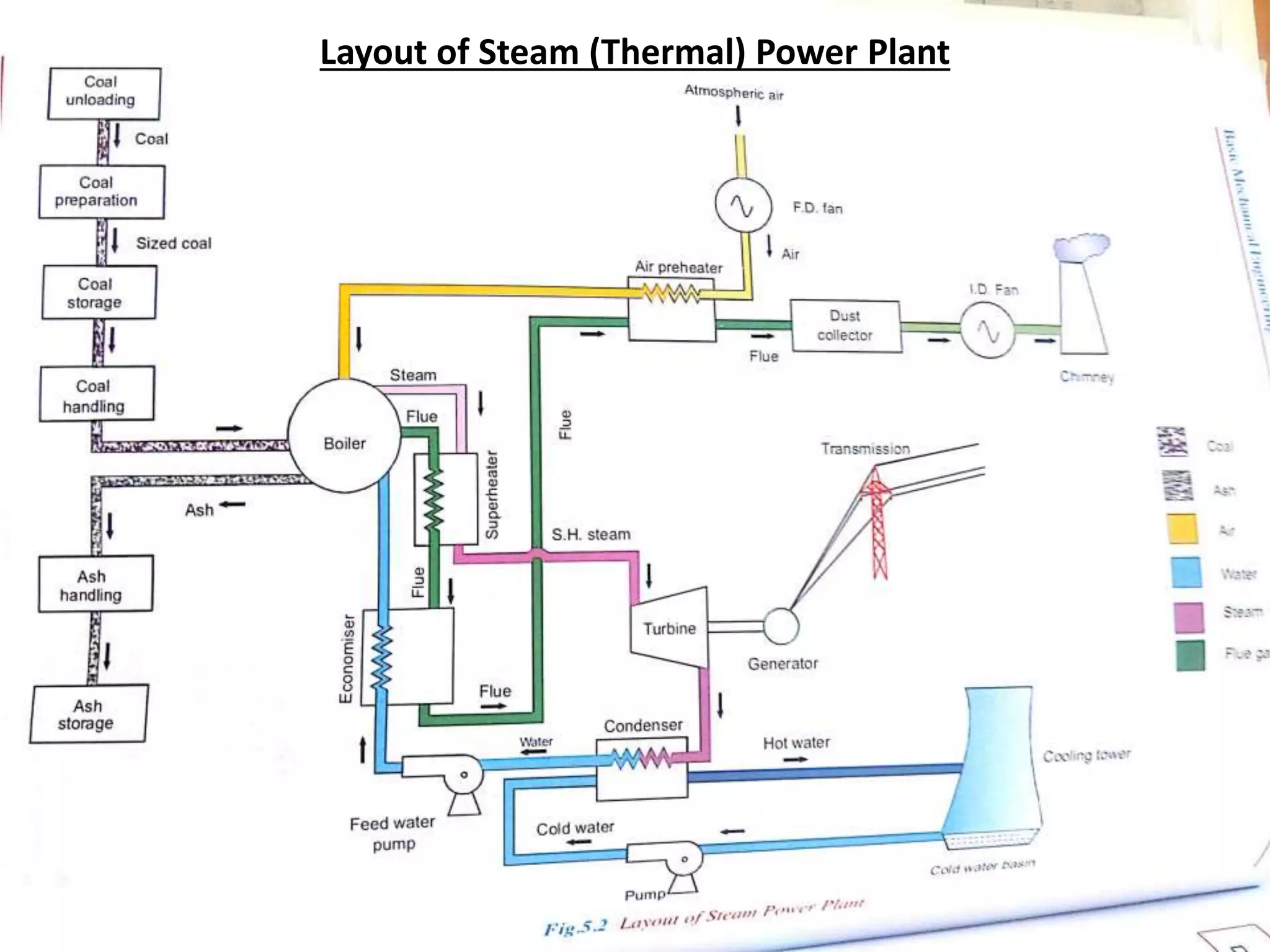

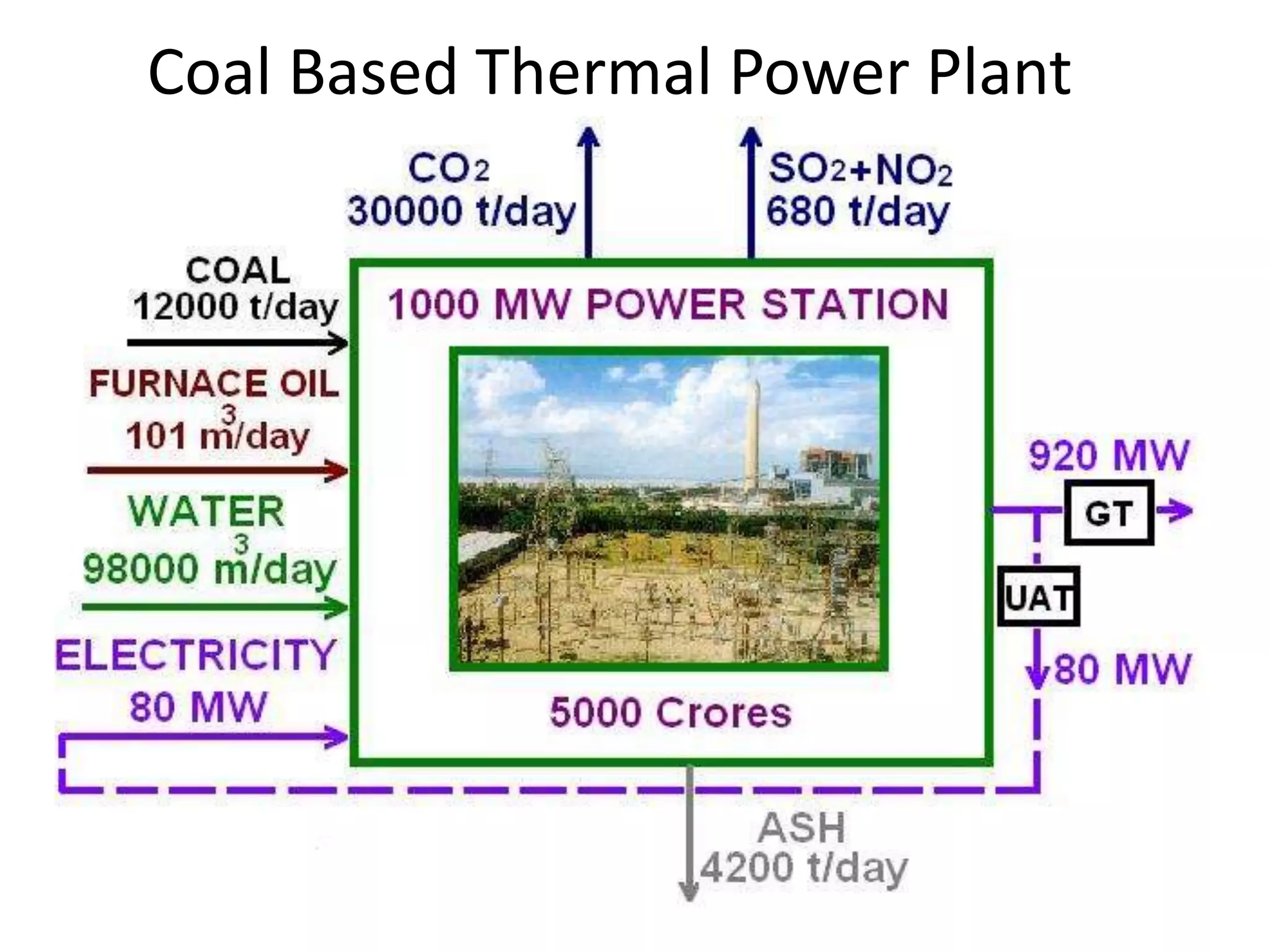

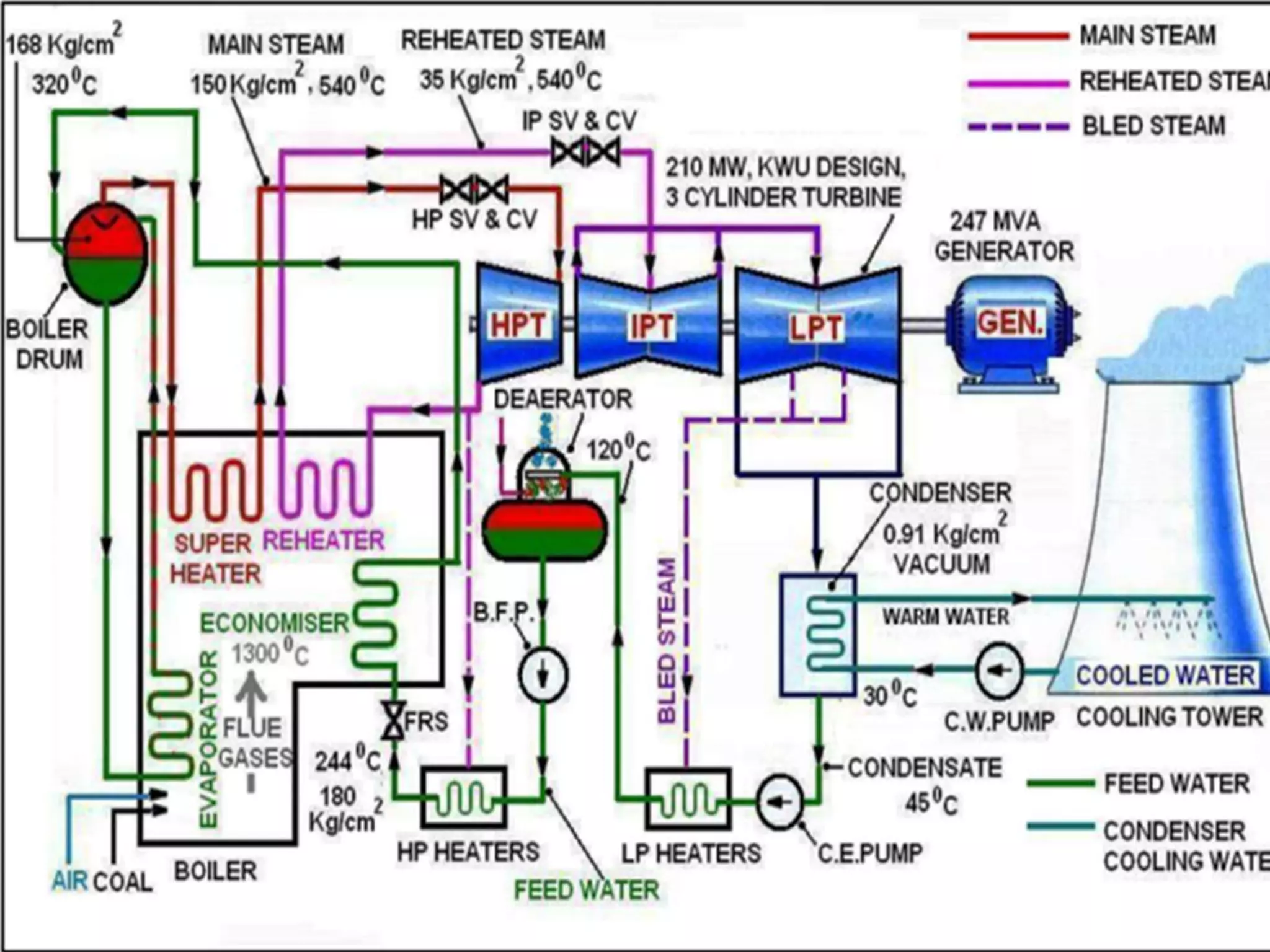

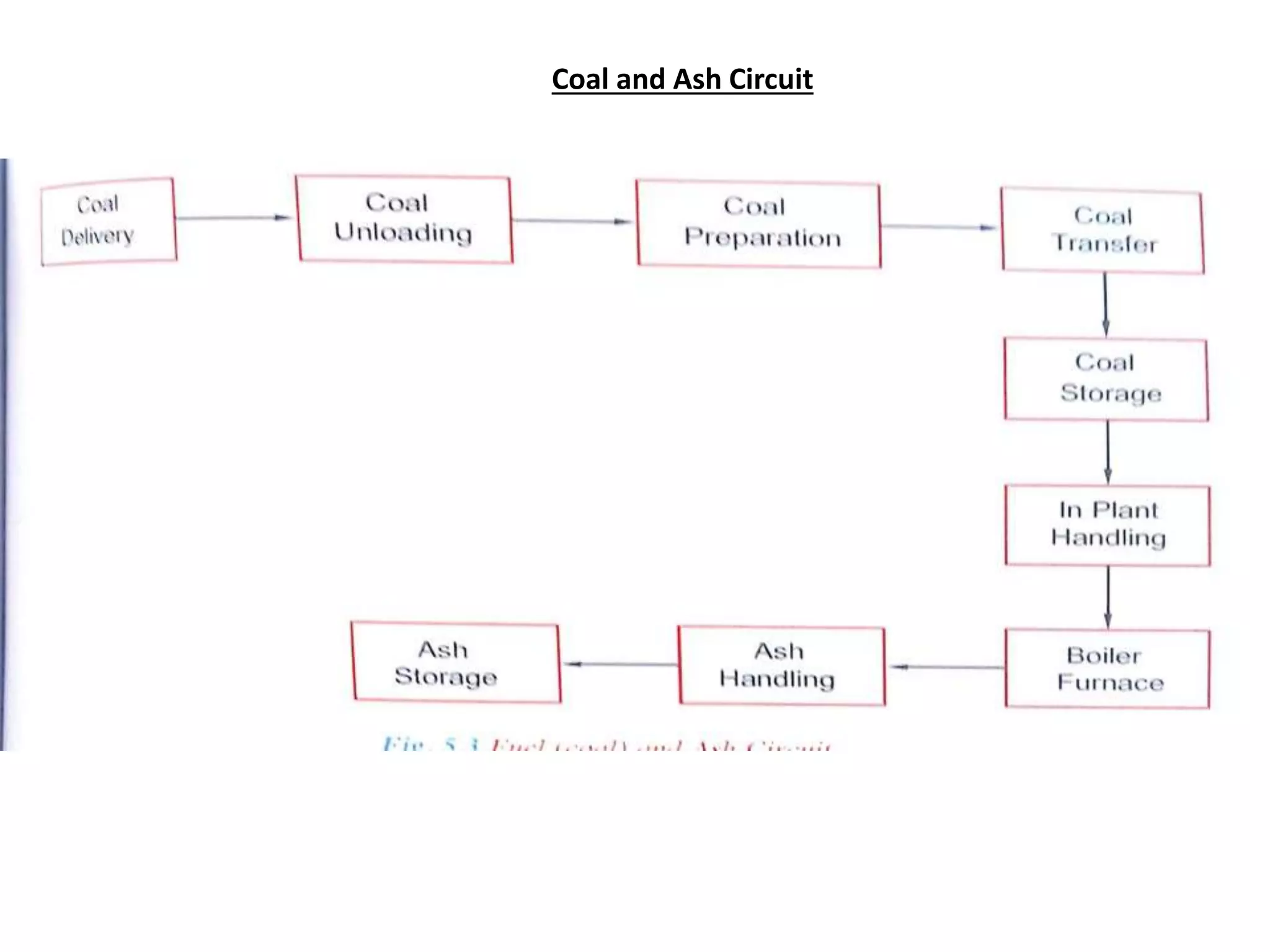

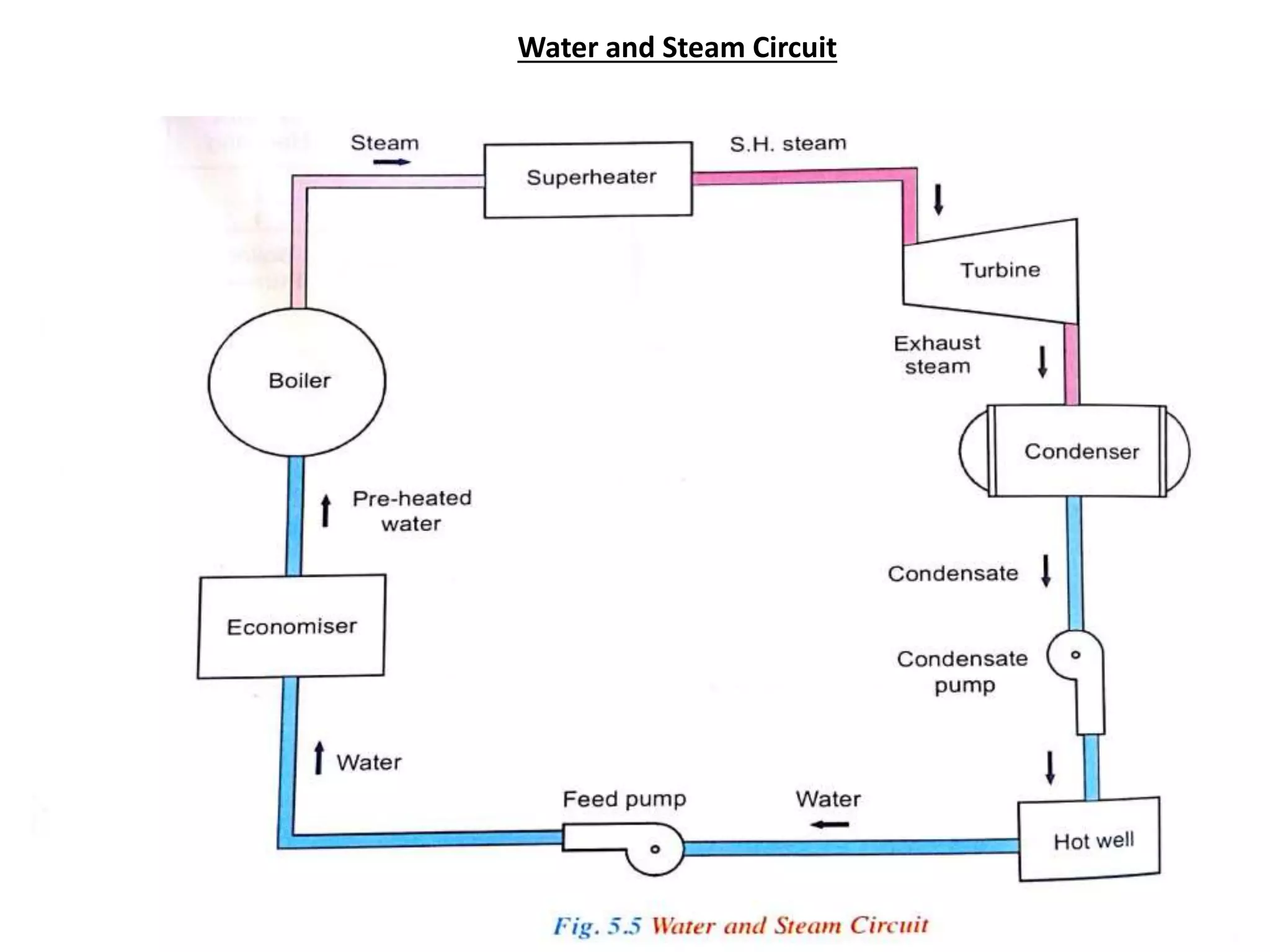

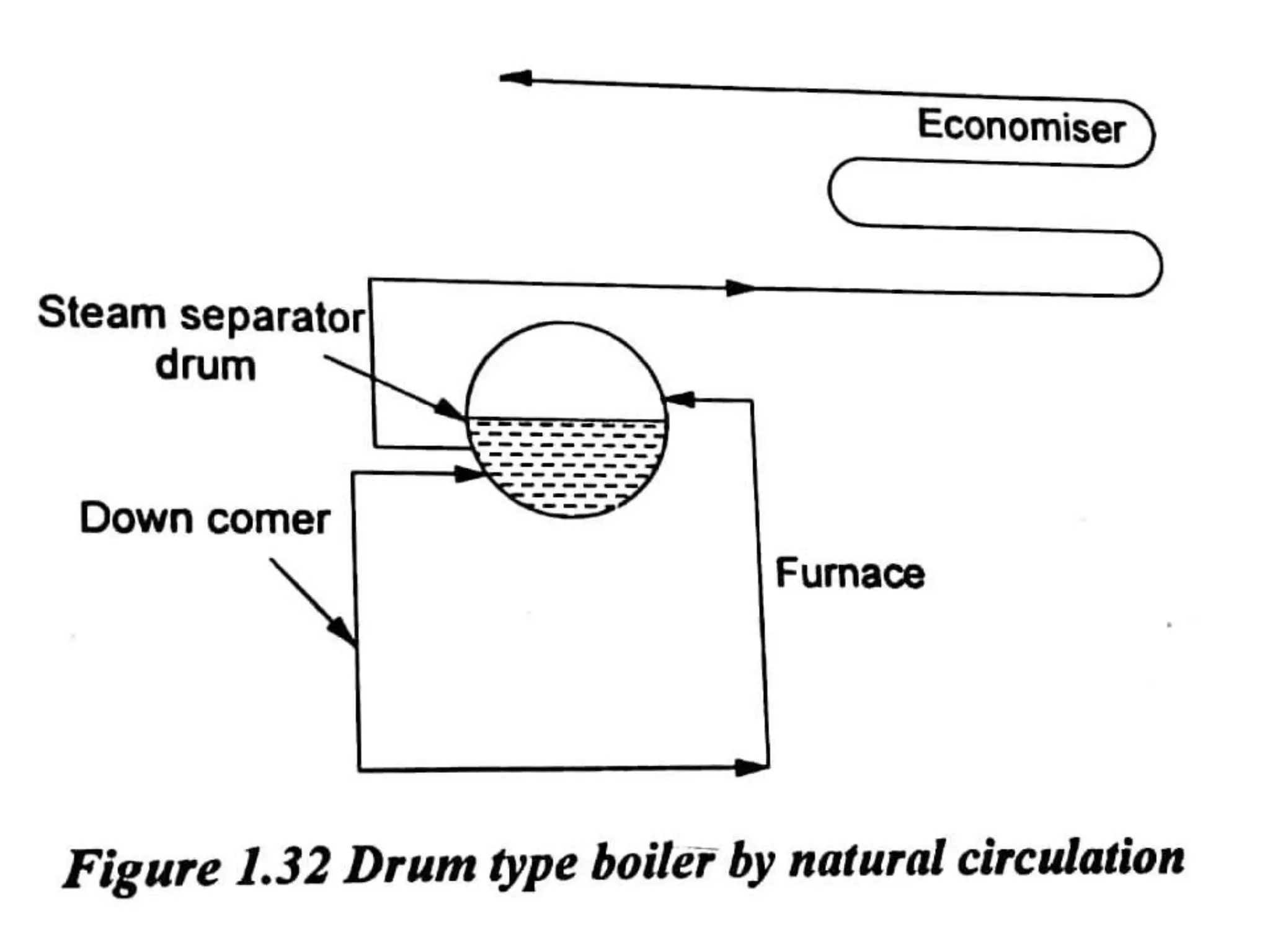

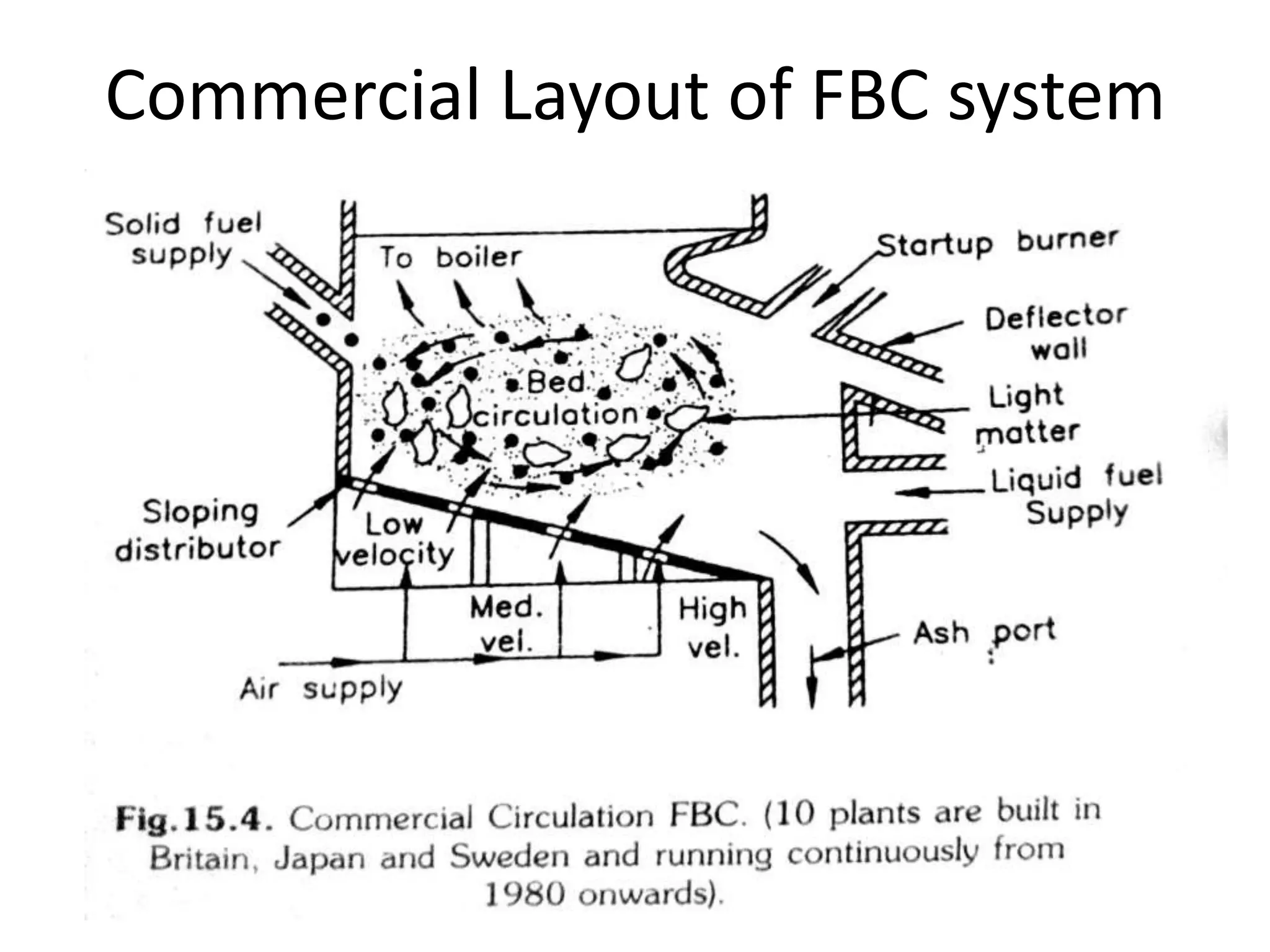

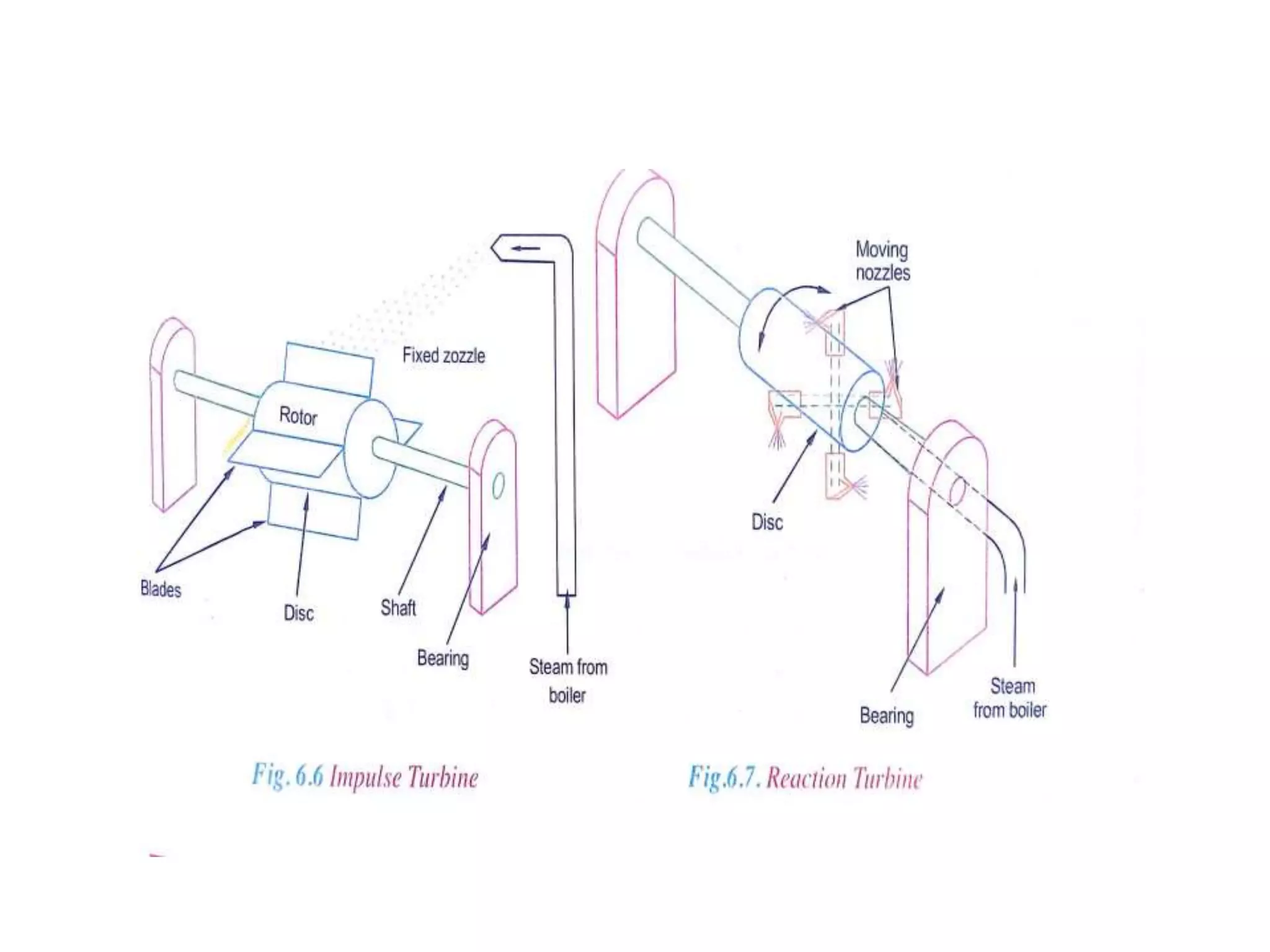

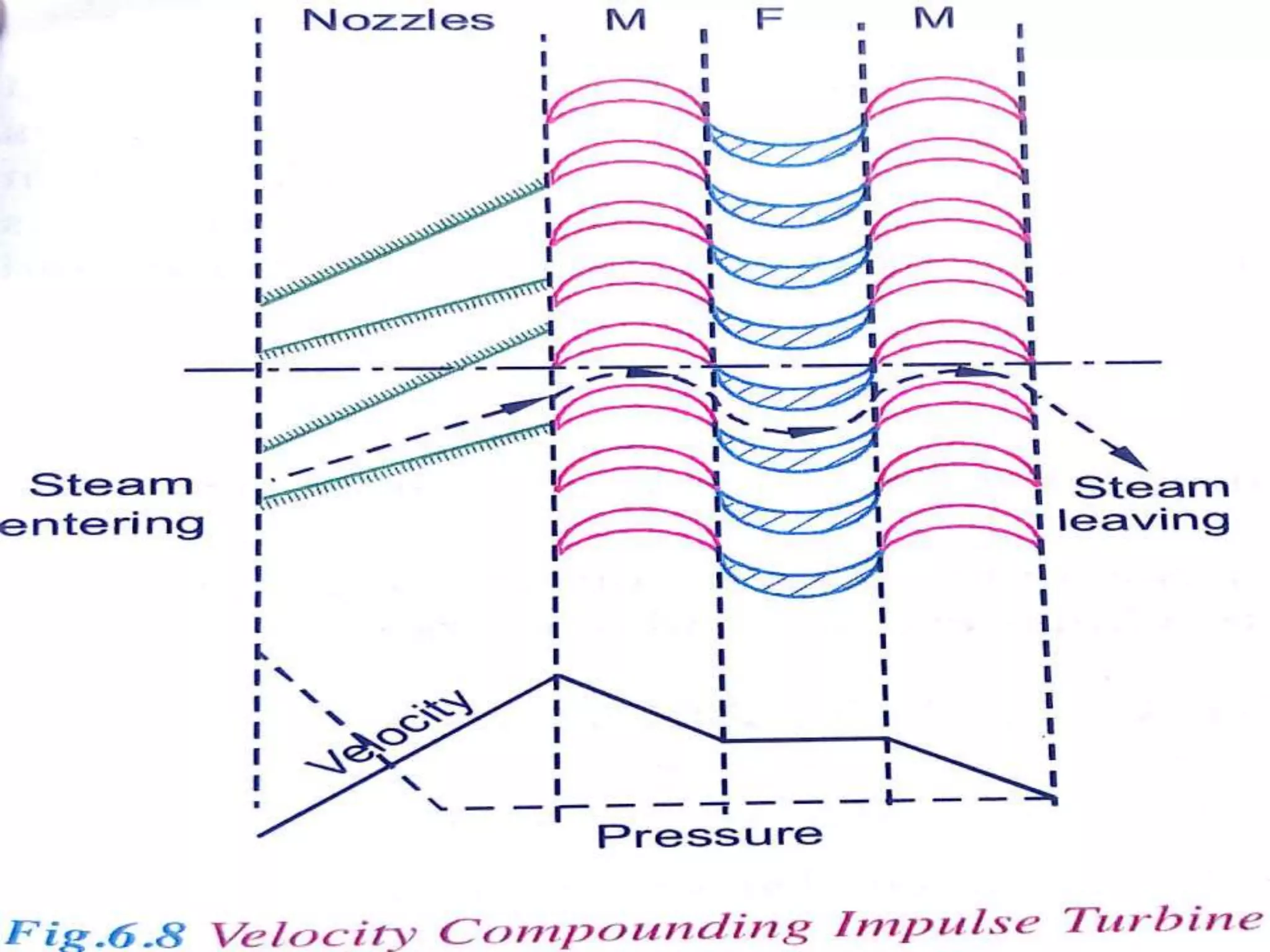

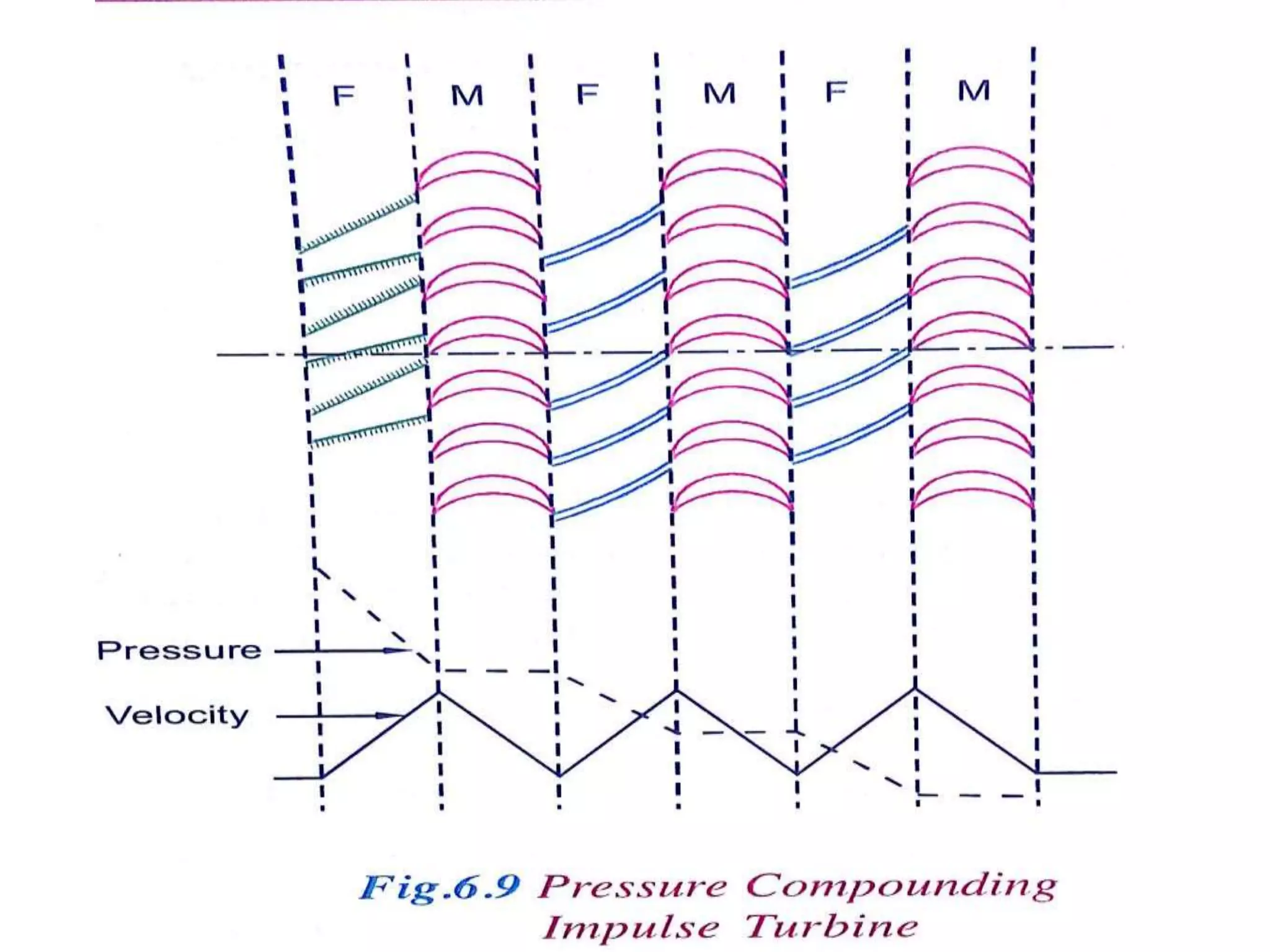

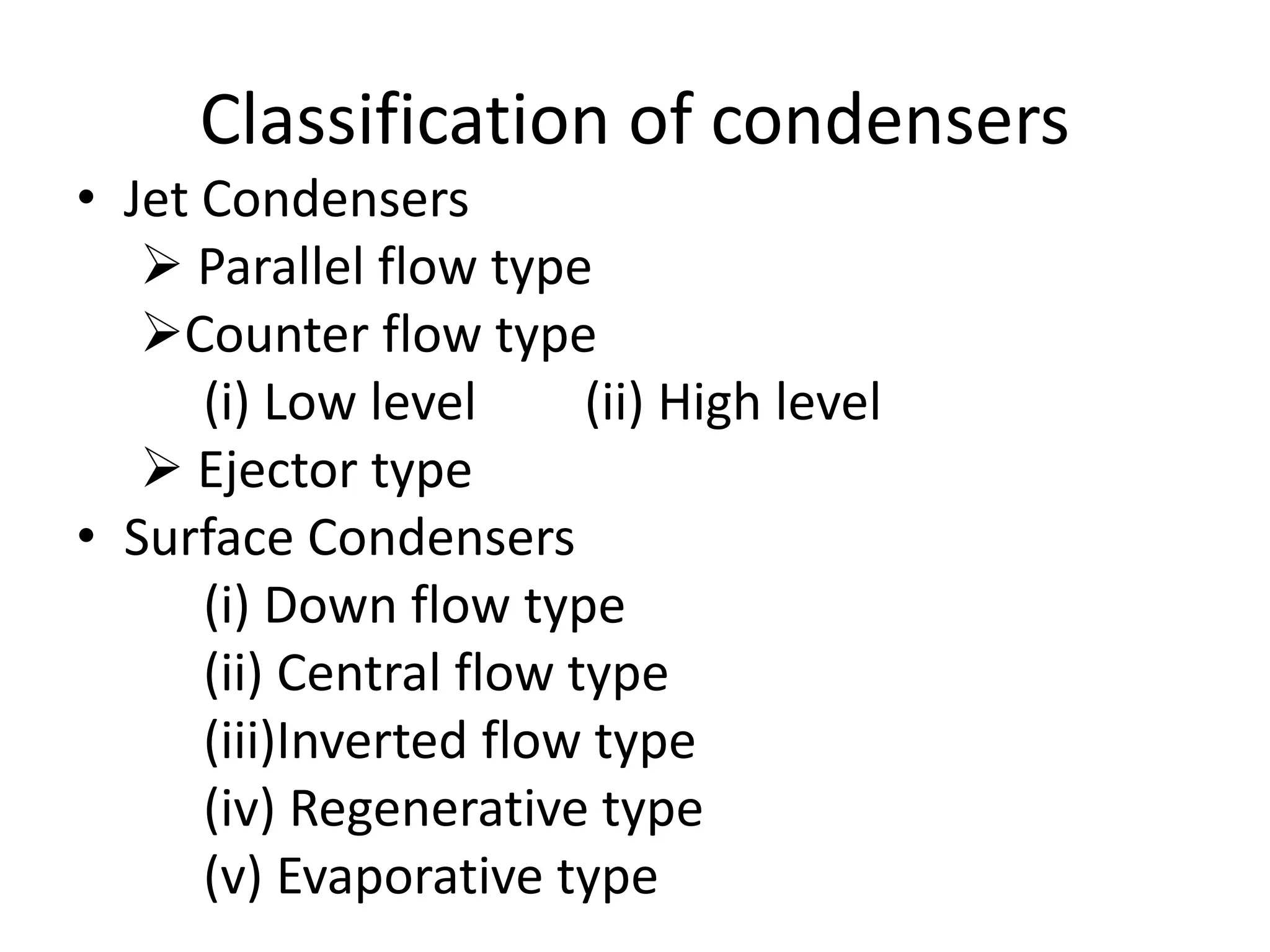

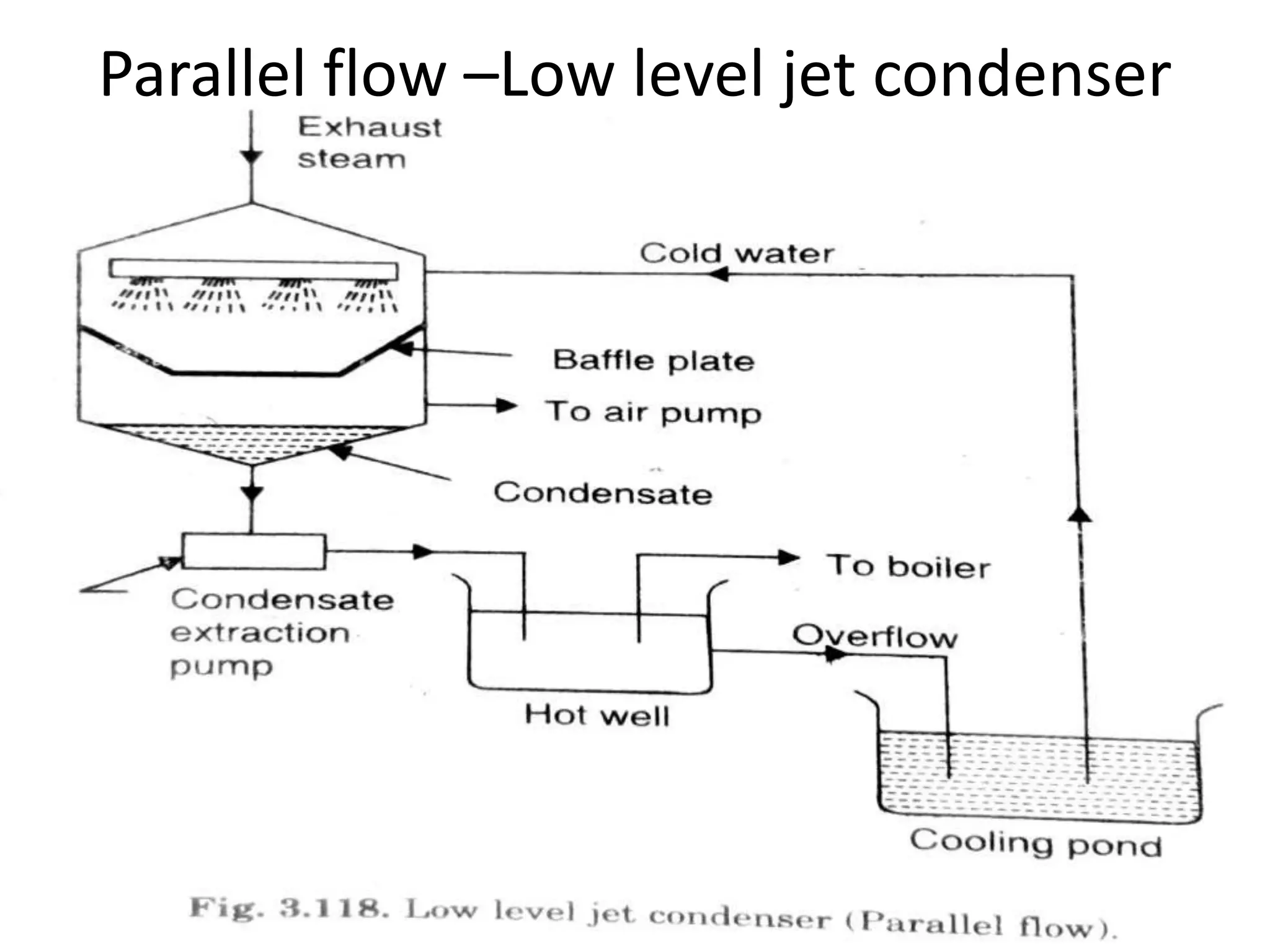

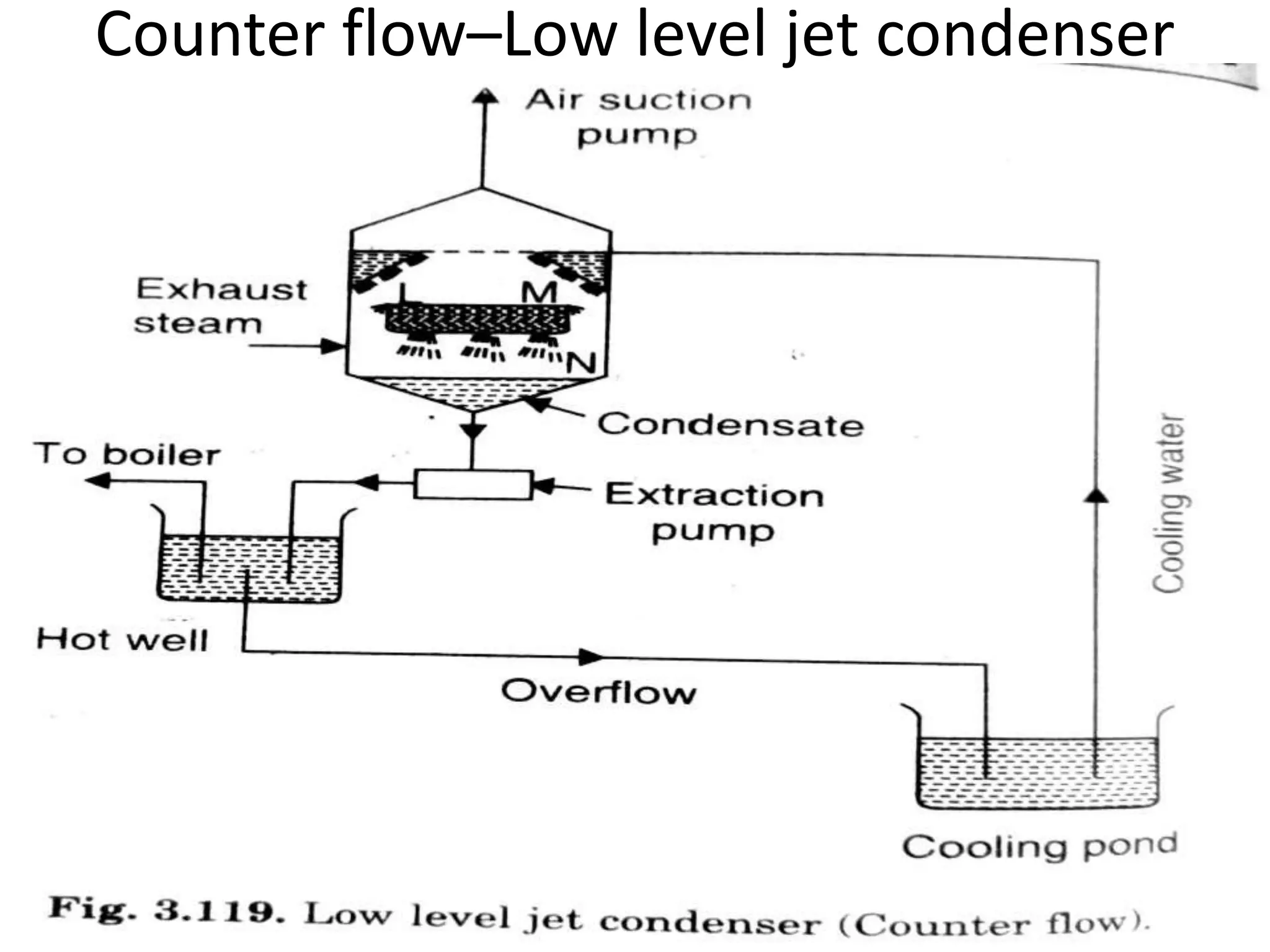

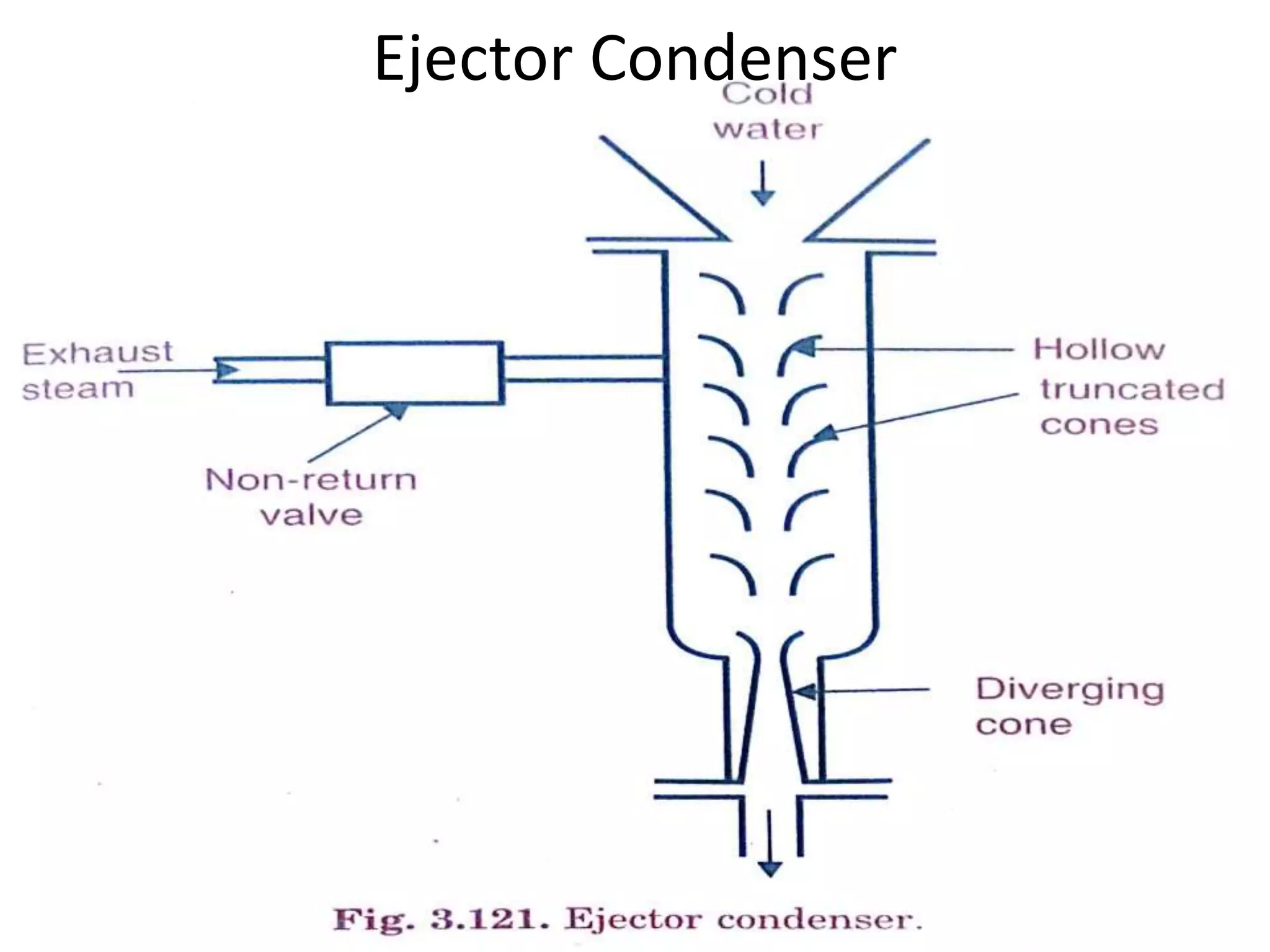

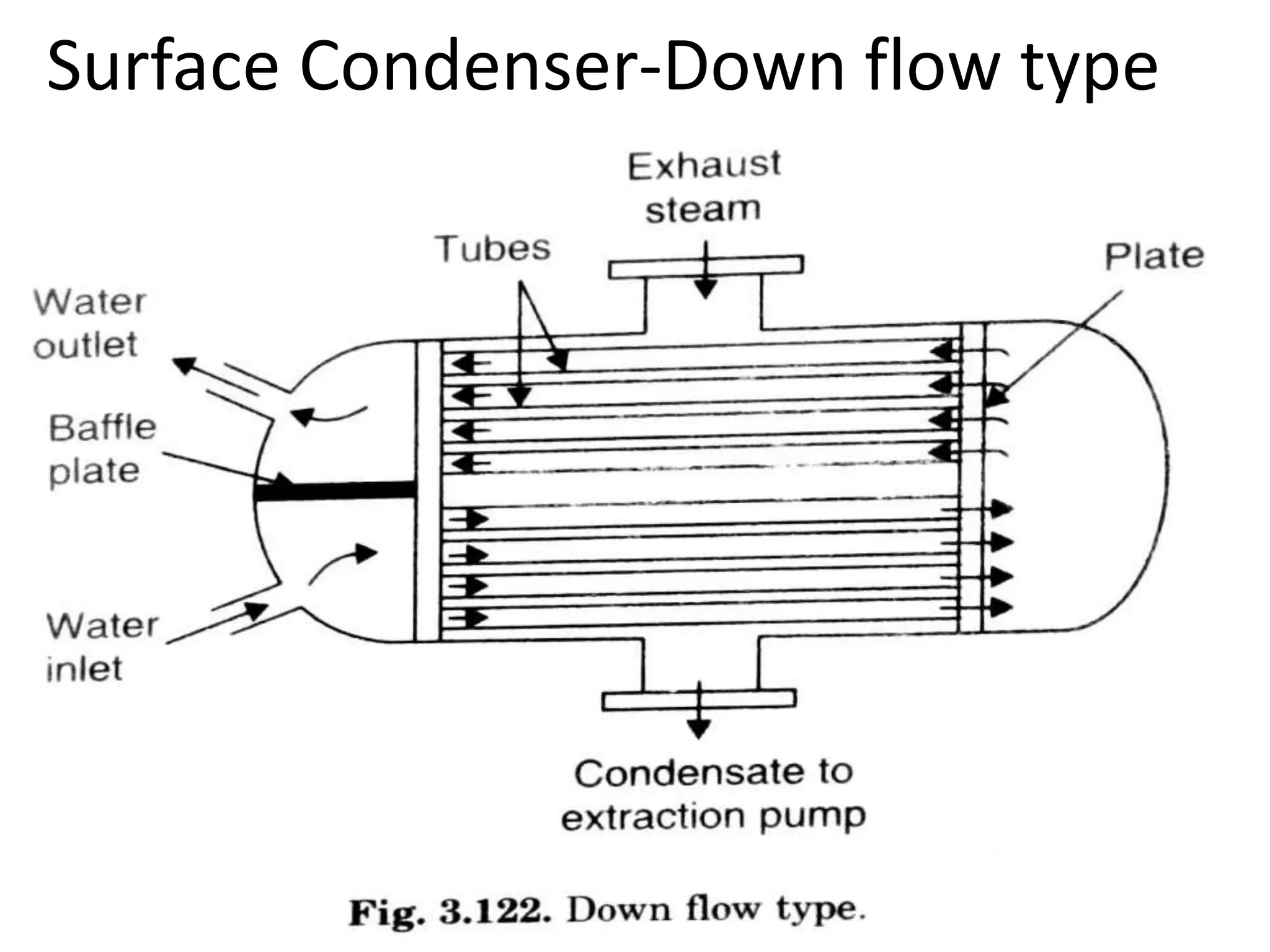

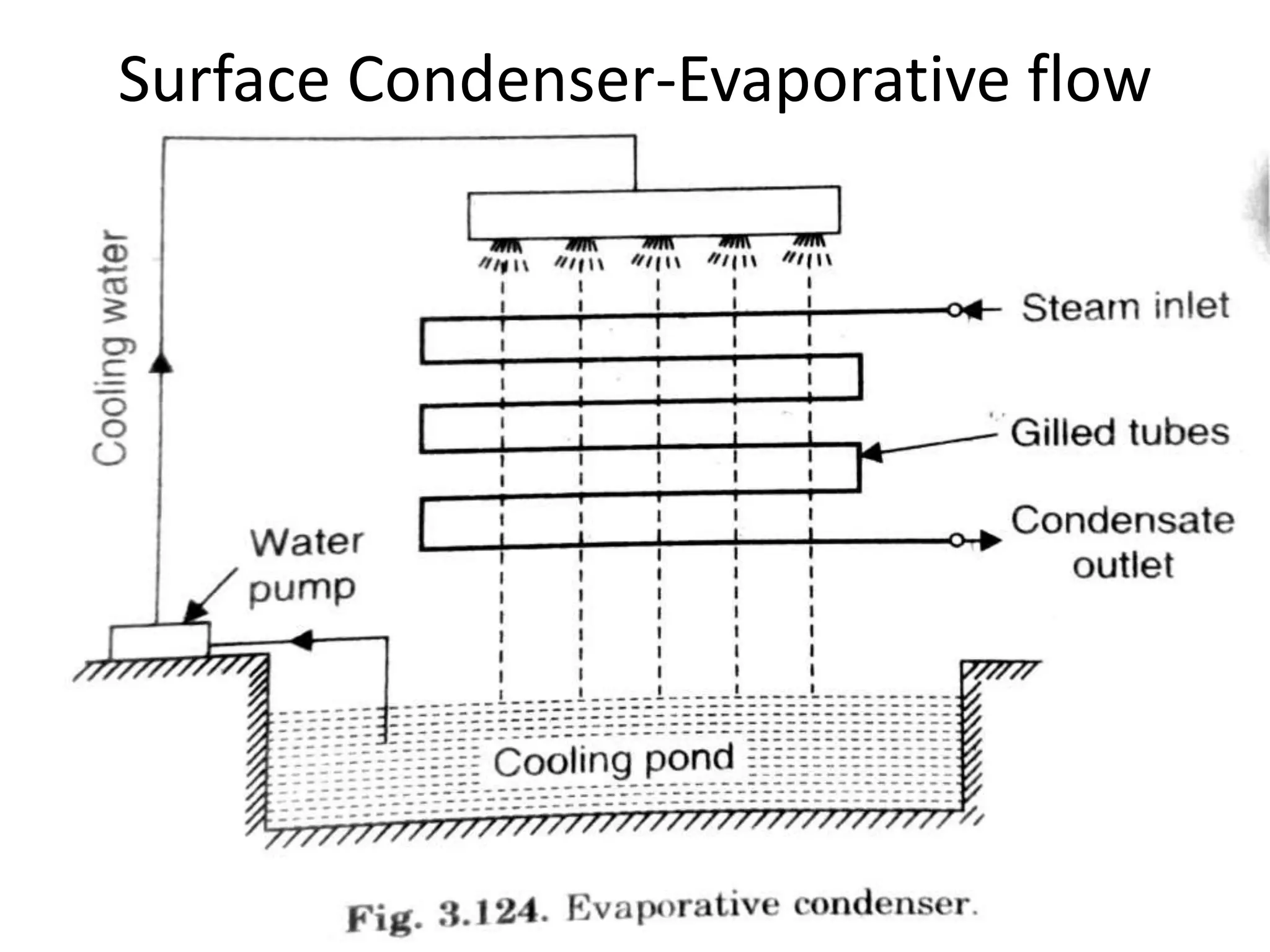

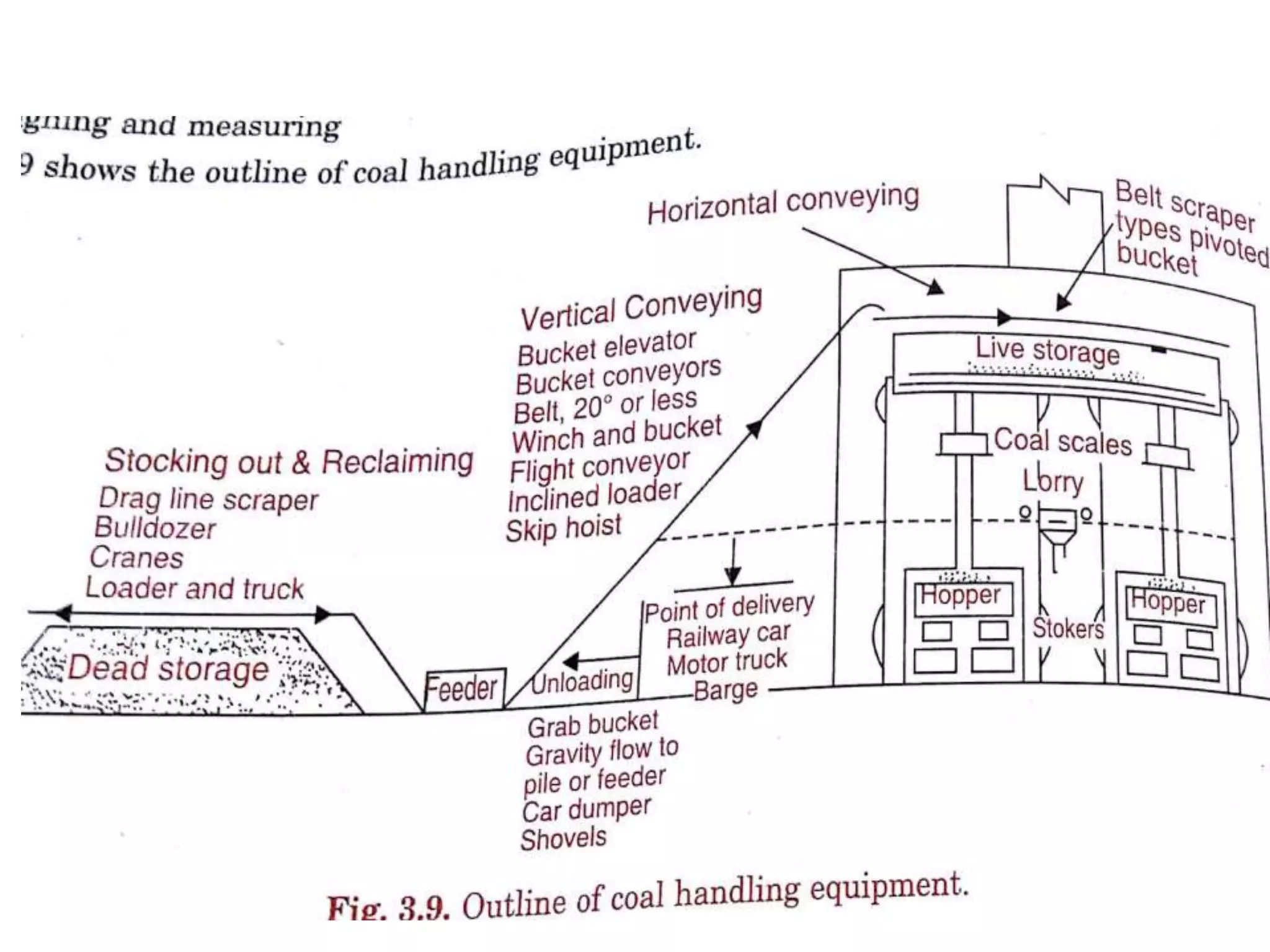

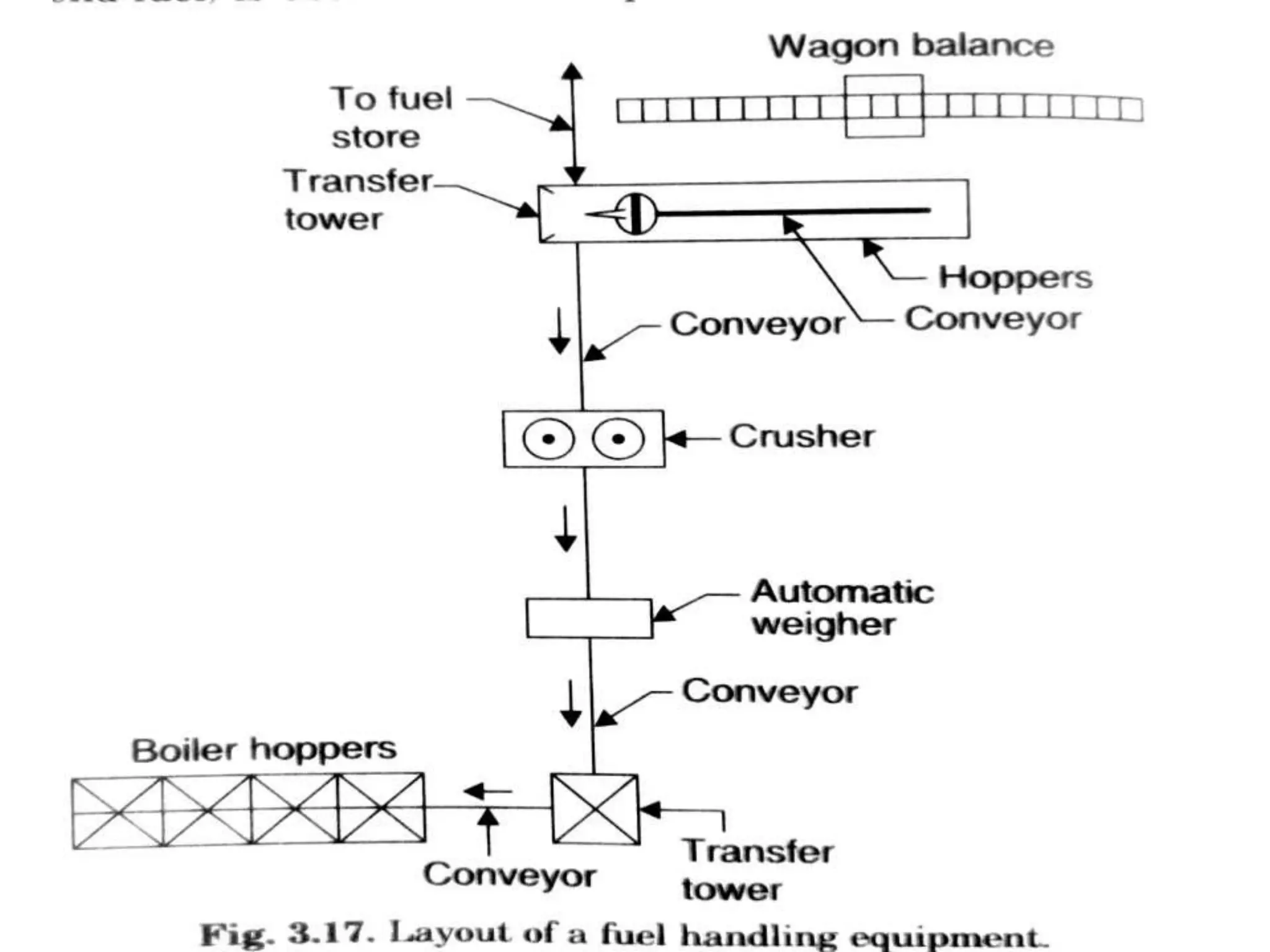

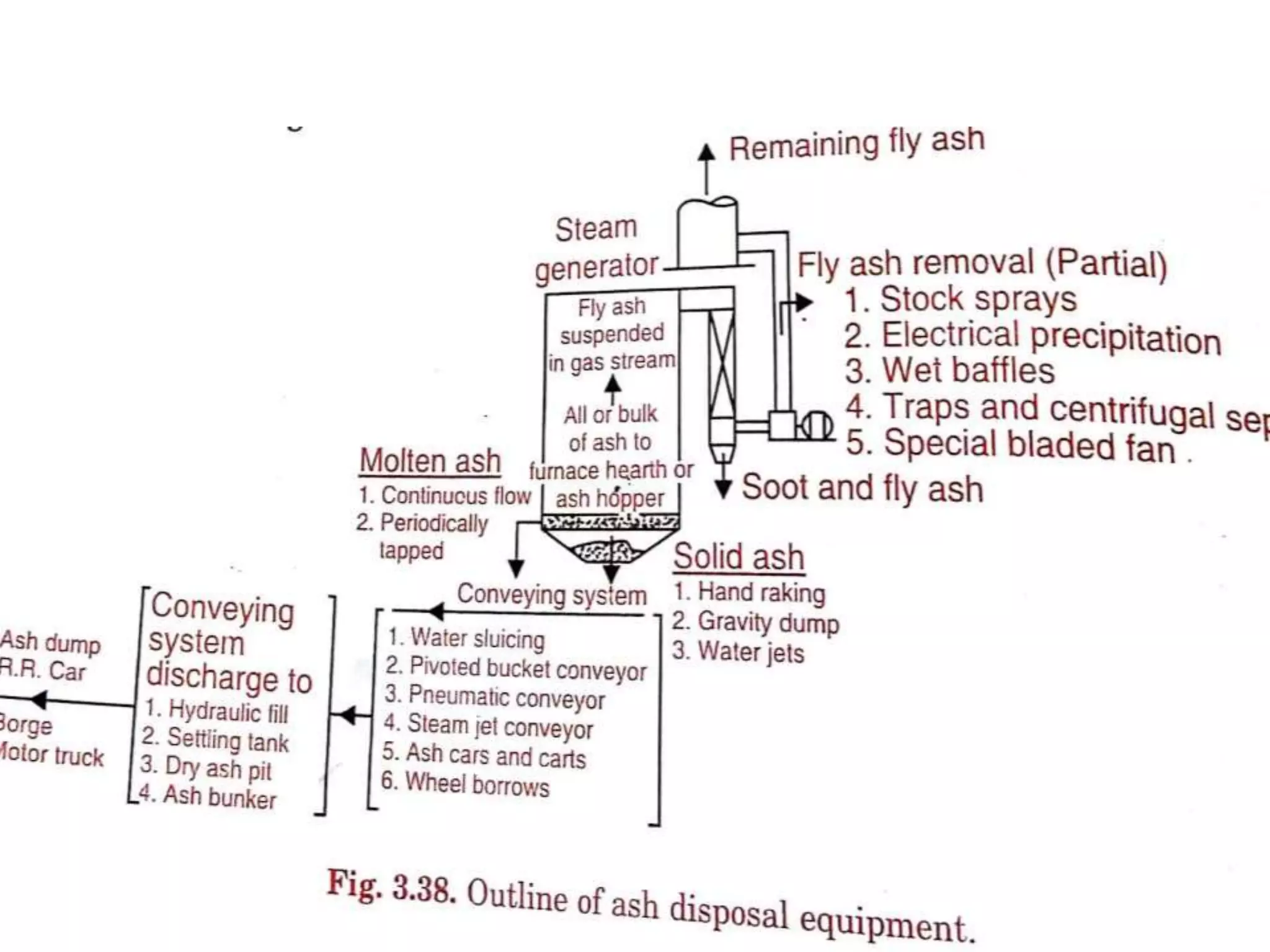

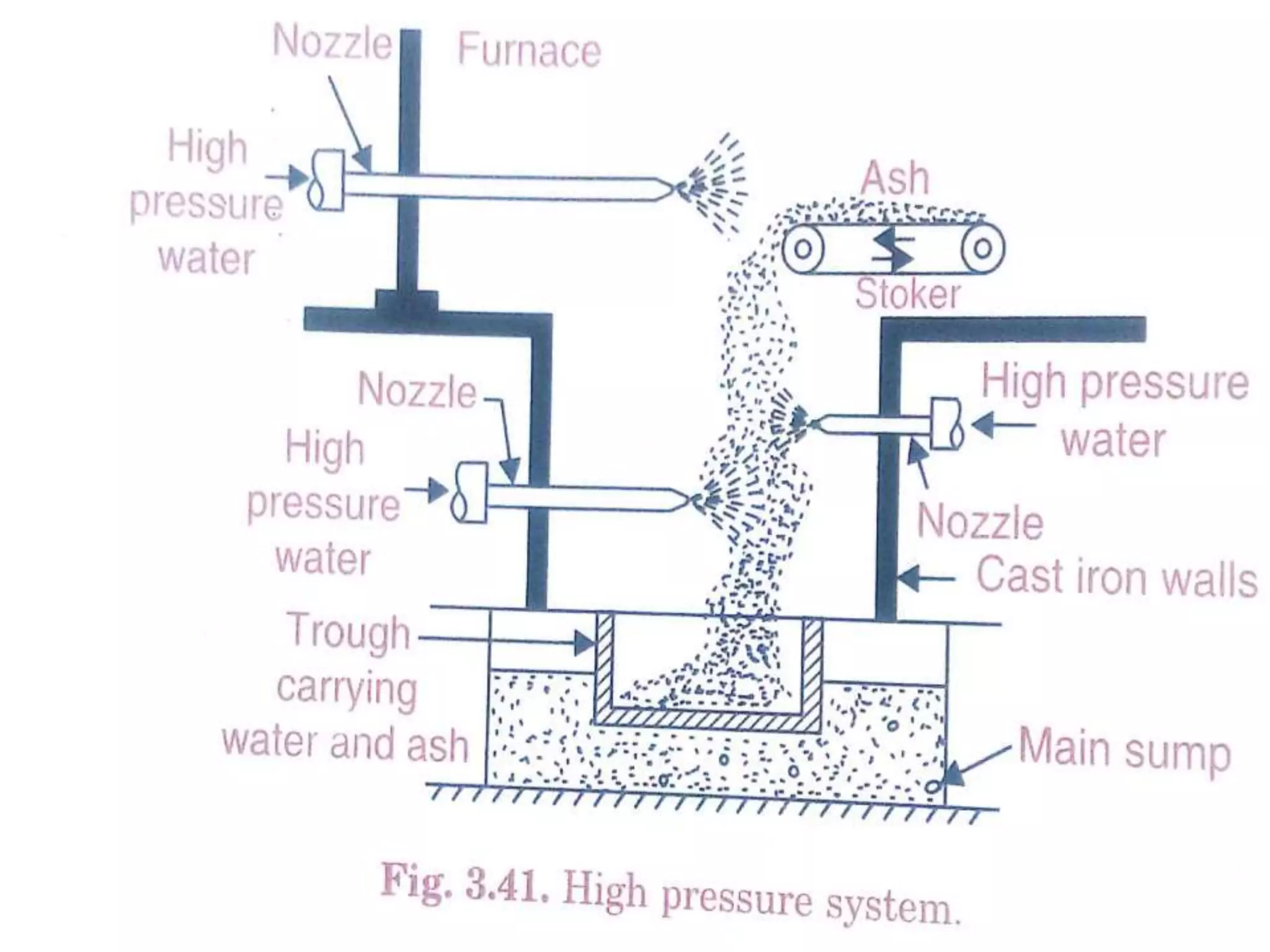

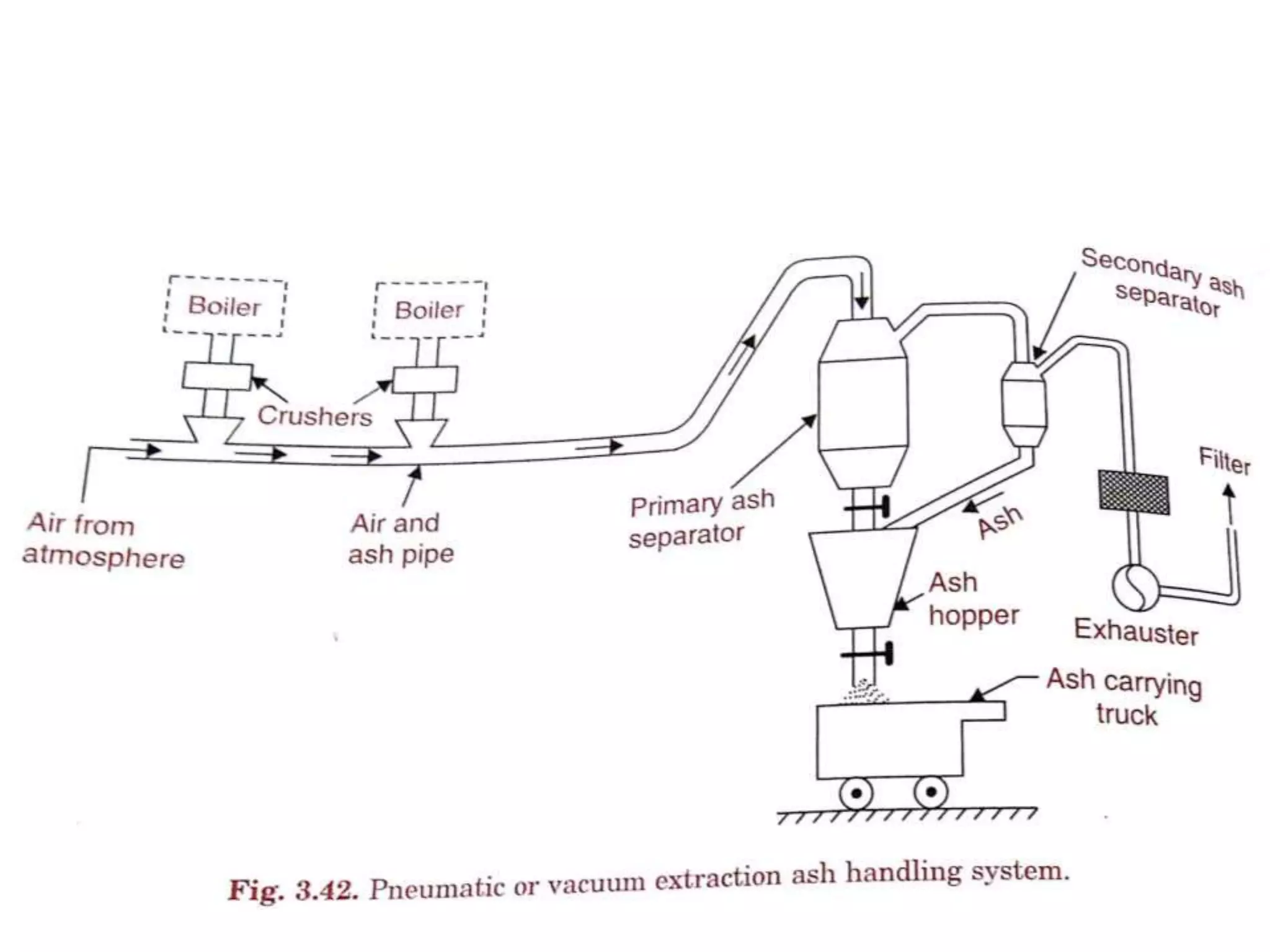

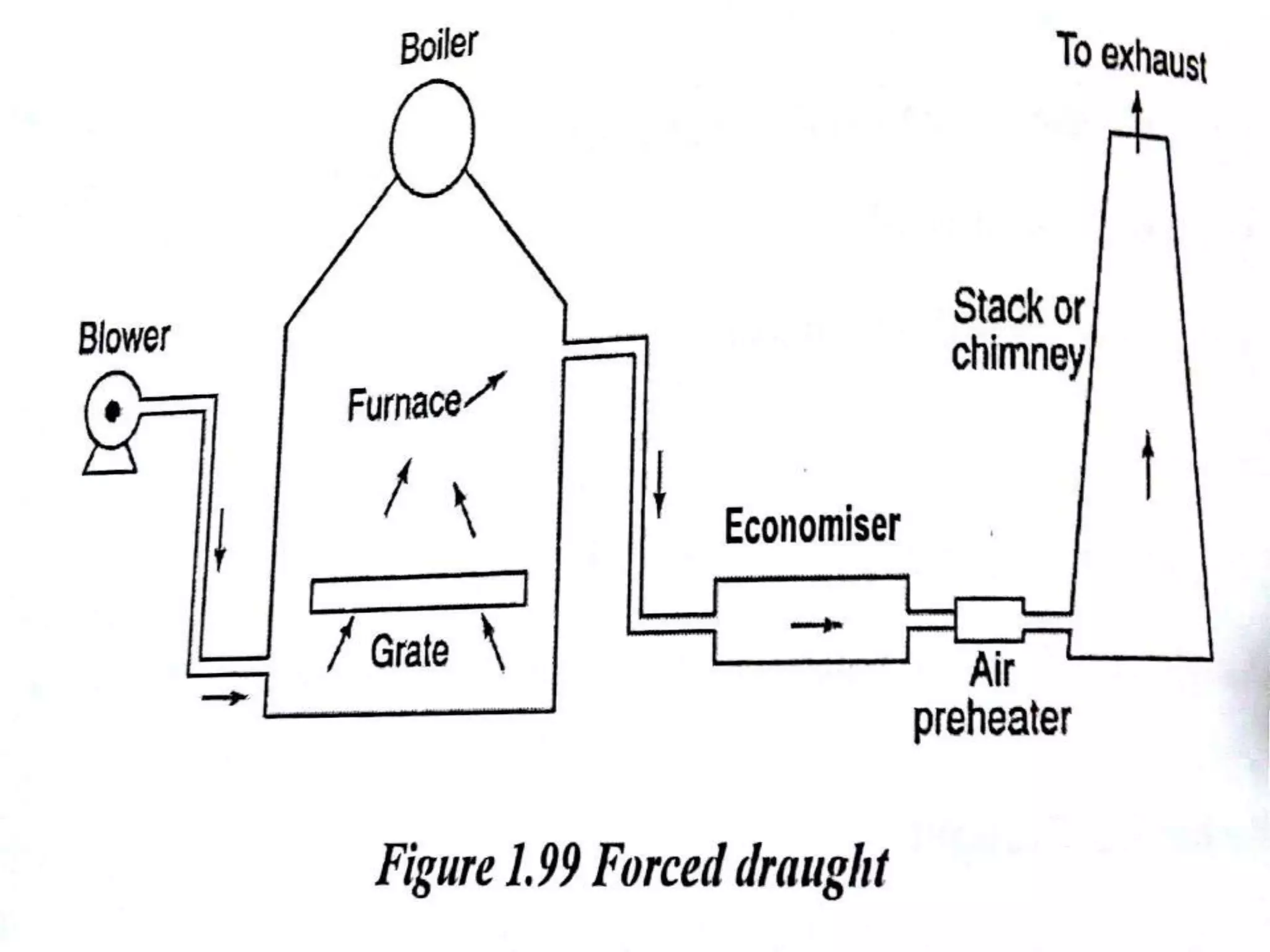

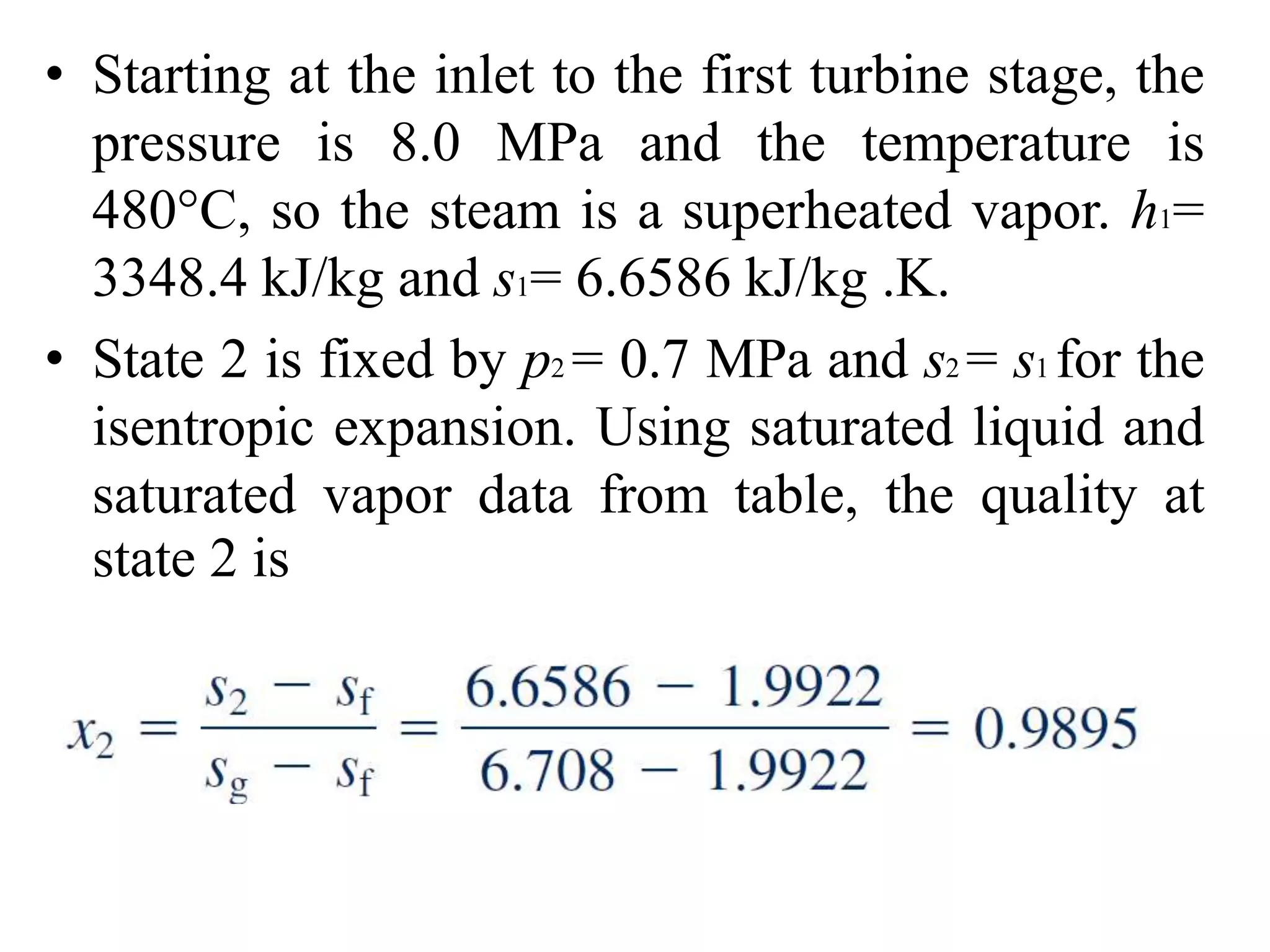

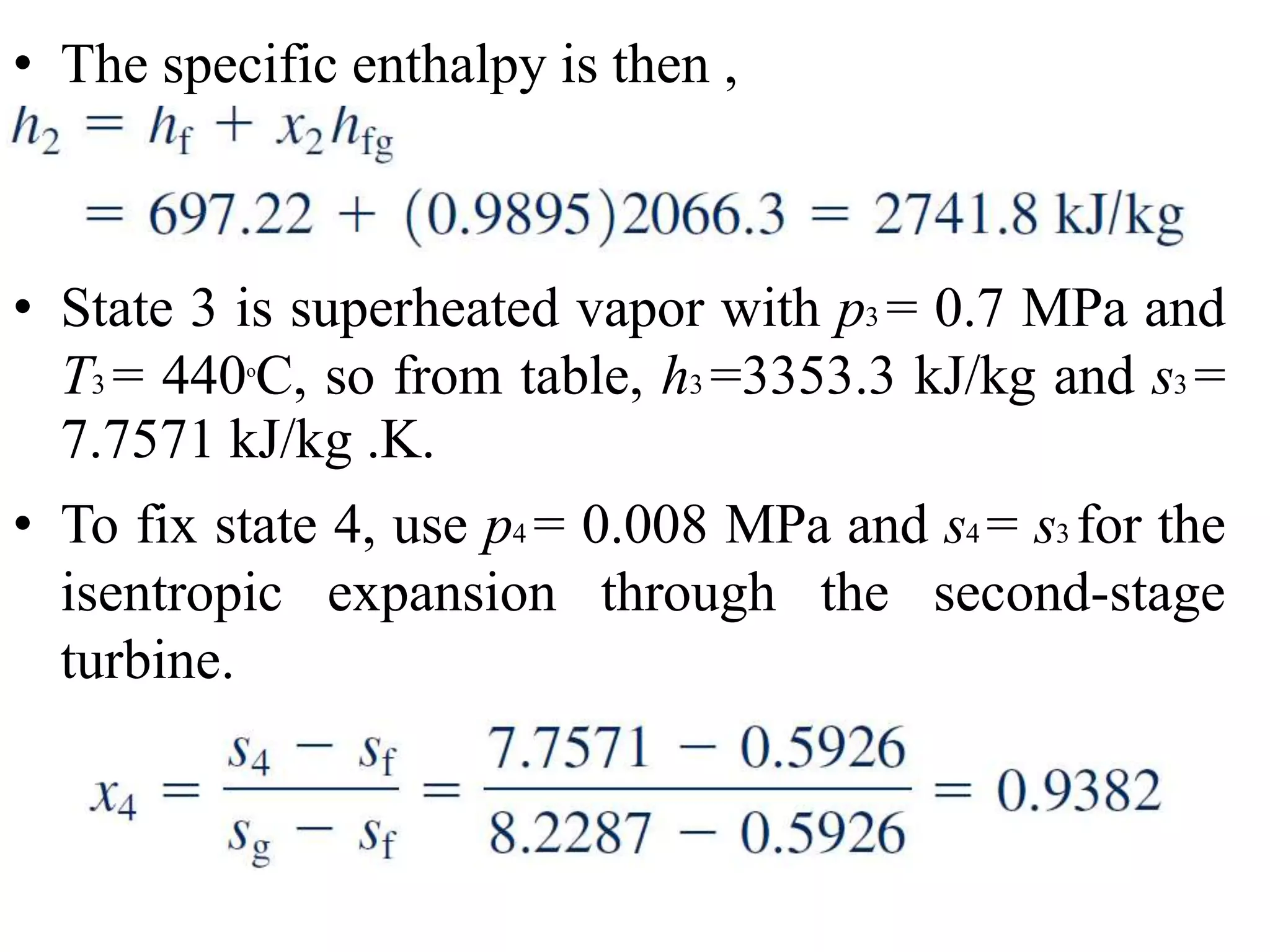

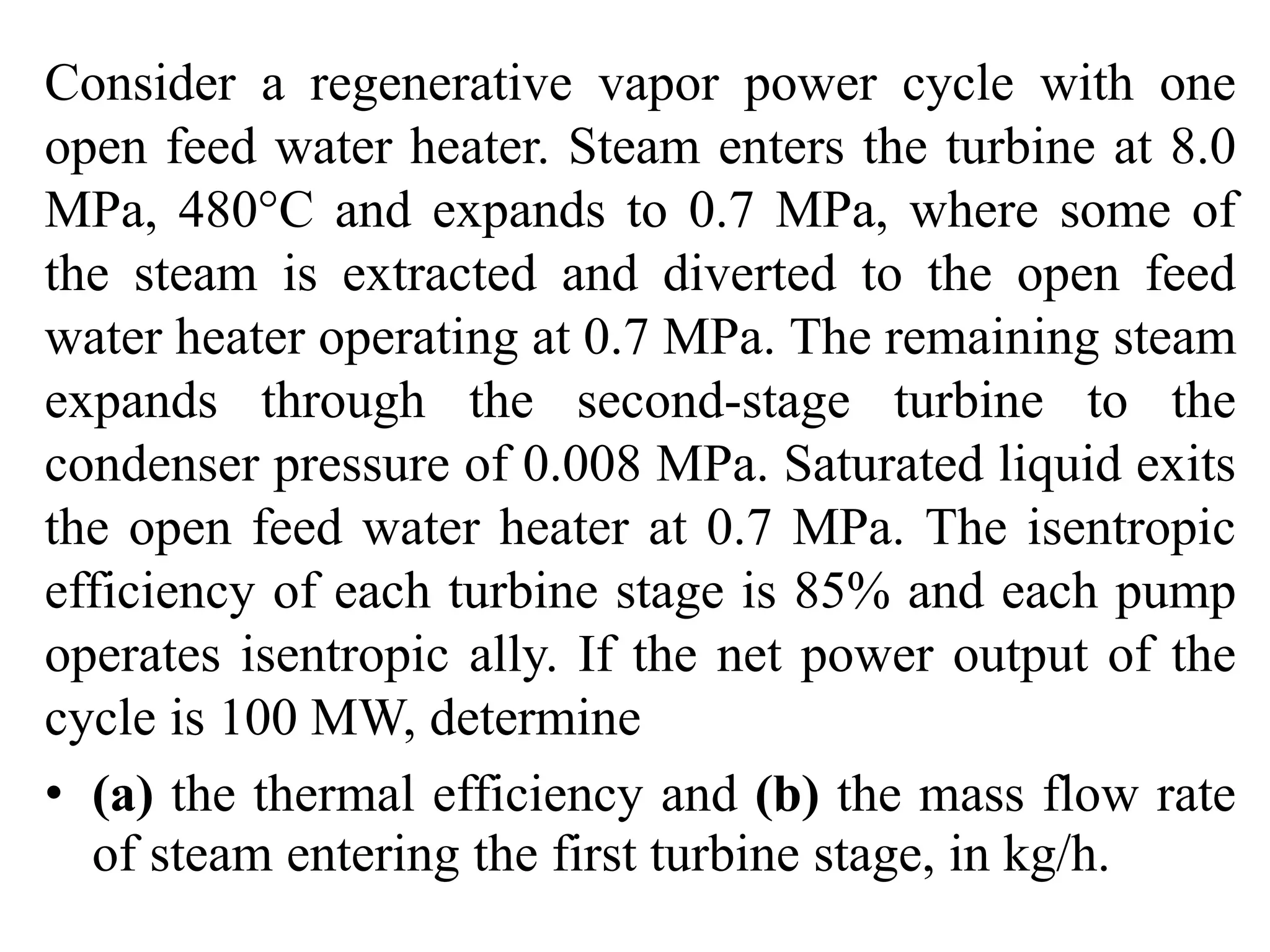

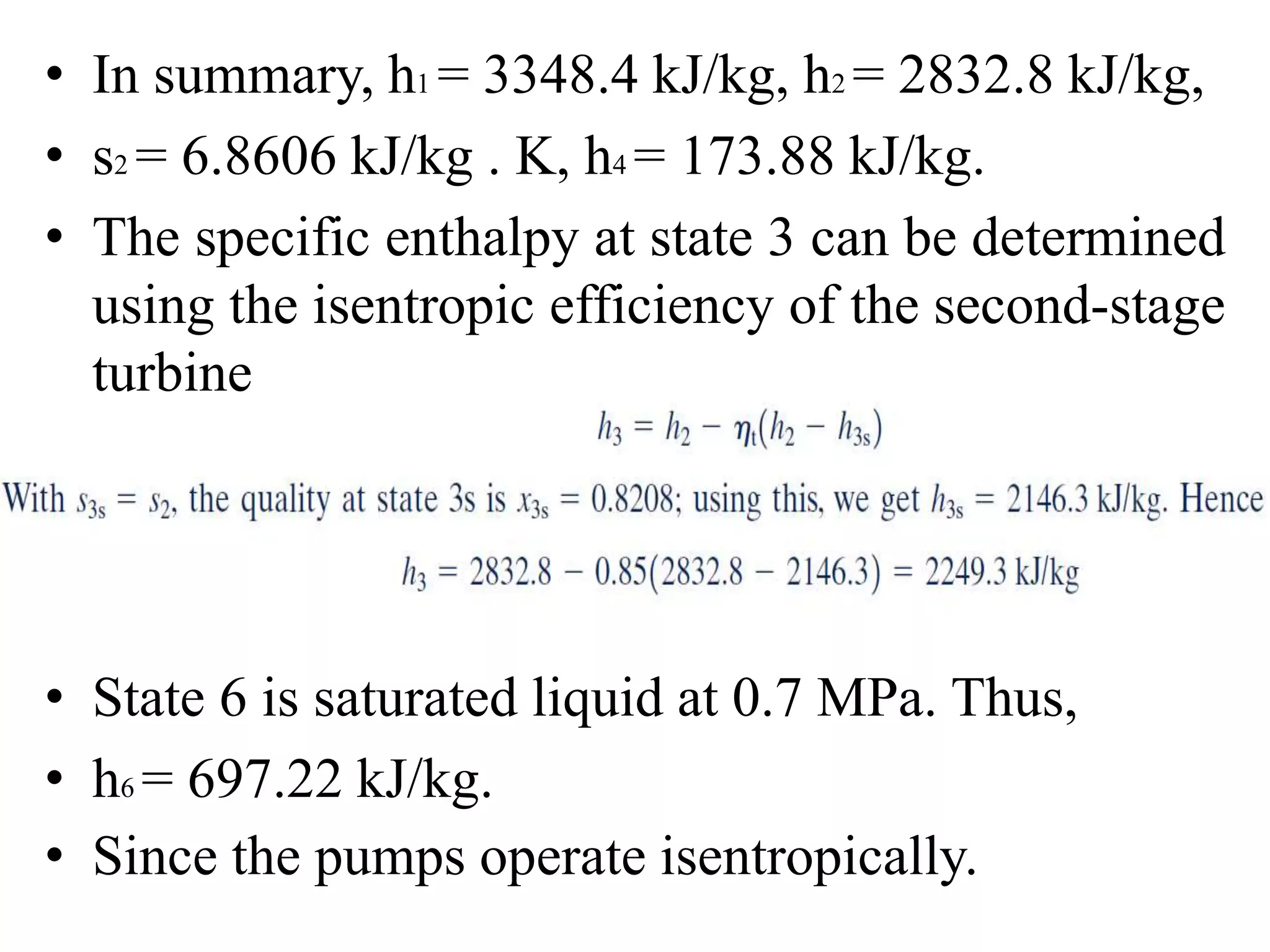

This document describes the key components and processes in a coal-based thermal power plant. There are four main circuits: 1) the coal and ash circuit which includes coal delivery, preparation, combustion in the boiler, and ash handling; 2) the air and flue gas circuit which includes fans that move air and exhaust gases through the plant; 3) the water and steam circuit where water is turned into steam to power the turbines; and 4) the cooling water circuit which condenses the exhaust steam and cools the plant. The document also discusses fluidized bed combustion boilers, steam turbines, condensers, and other important systems within a coal power plant.