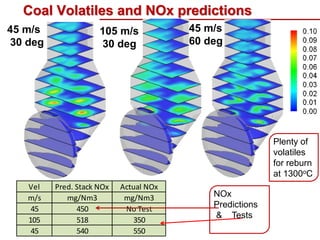

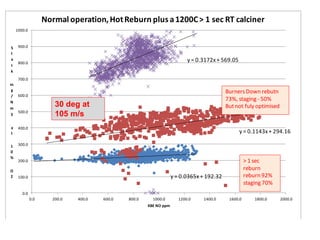

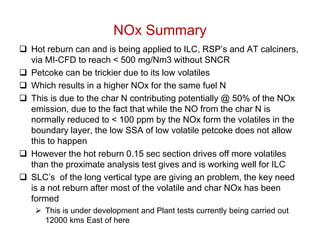

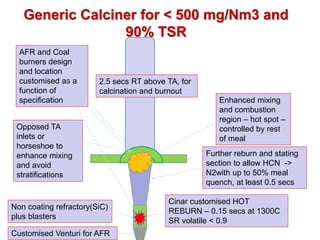

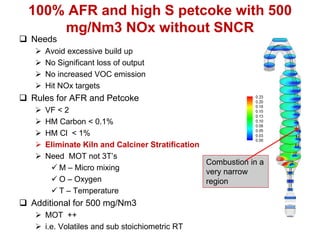

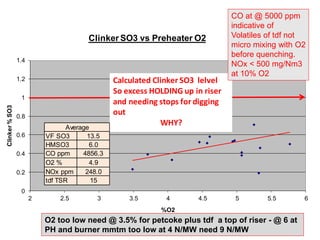

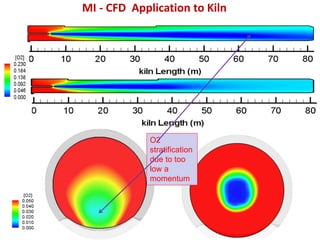

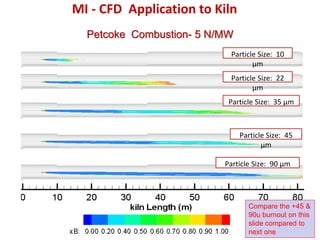

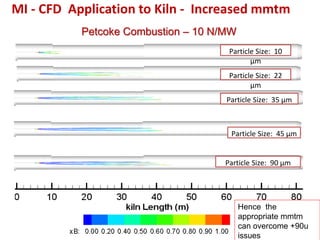

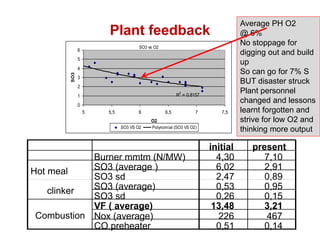

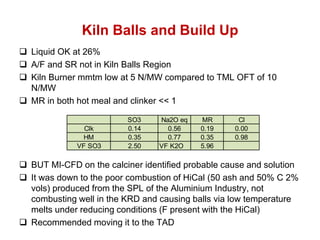

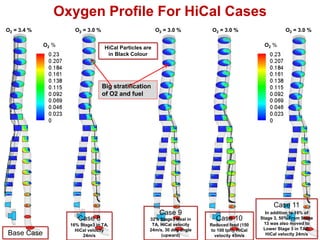

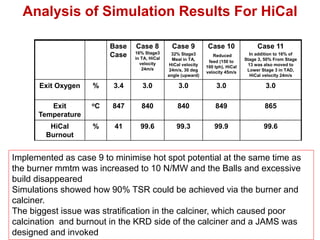

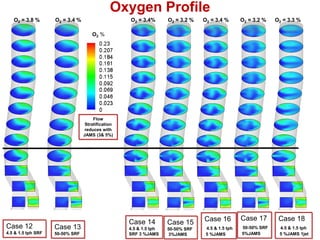

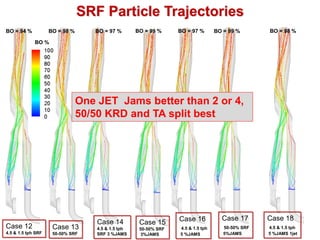

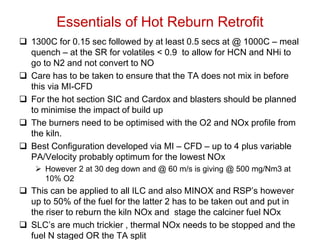

The document discusses achieving 100% alternative fuel rates (AFR) and using high sulfur petcoke fuels to produce cement clinker with NOx emissions below 500 mg/Nm3 without selective non-catalytic reduction (SNCR). It outlines fundamental rules and shares case studies where plants achieved these goals. Micro-mixing of oxygen, volatiles, and precise temperature control in the kiln and calciner were critical to ensure proper combustion. Computational fluid dynamics (CFD) modeling helped identify issues like stratification and recommend solutions like increased burner momentum. Maintaining the right operating parameters and combustion fundamentals can allow plants to use more alternative fuels and reduce emissions.

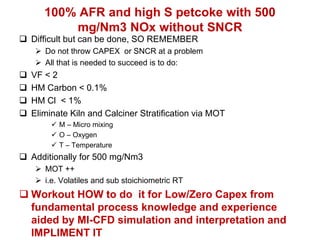

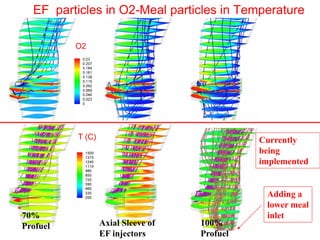

![Oxygen Mass Fraction [-]

Original

Modified

Original Modified

Burnout % 70 93

Calcination % 70 90](https://image.slidesharecdn.com/cemtechpaper-130308012036-phpapp02/85/100-High-S-petcoke-and-AFR-with-lt-500-mg-Nm3-NOx-25-320.jpg)

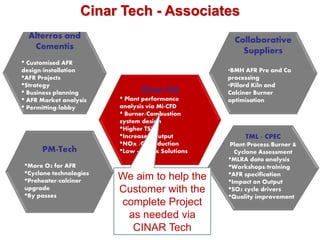

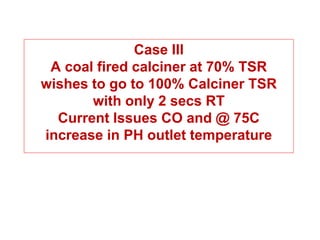

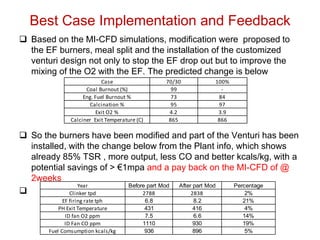

![The EF releases

Oxygen Profiles / Fuel Trajectories if volatiles fast,

but is then

quenched too

fast by the meal

and then travels

in a low O2

Case Base Case region which

Coal Burnout (%) 99 makes the

EF Burnout % 73 burnout poor

Total Burnout % 81

Calcination 95 Near the walls of

there are oxygen

Coal / O2 EF / O2 rich areas where

available oxygen

would enhance

the burnout

O2 [m/m]](https://image.slidesharecdn.com/cemtechpaper-130308012036-phpapp02/85/100-High-S-petcoke-and-AFR-with-lt-500-mg-Nm3-NOx-26-320.jpg)

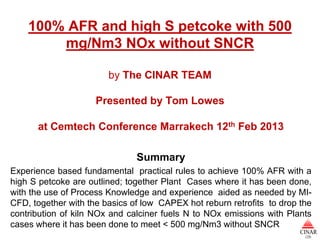

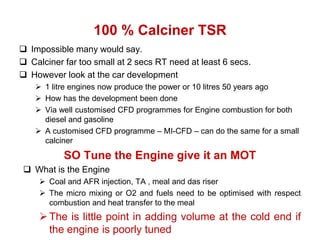

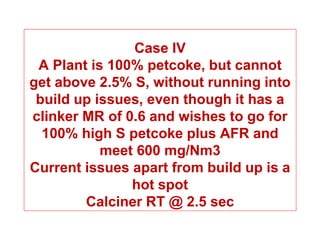

![Meal and Fuel Particles Tracking – current operation

Meal Particles

Av. Burnout: 83% Av. Calc: 75% Fuel Particles & & Temperature

O2

T [oC]

Burnout /

Calcination O2 [kg/kg]

Poor burnout/ calcination plus a hot spot

Engine need TUNING](https://image.slidesharecdn.com/cemtechpaper-130308012036-phpapp02/85/100-High-S-petcoke-and-AFR-with-lt-500-mg-Nm3-NOx-30-320.jpg)

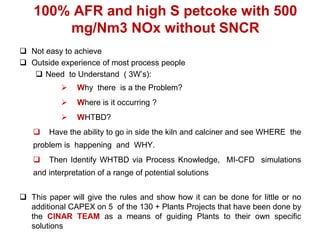

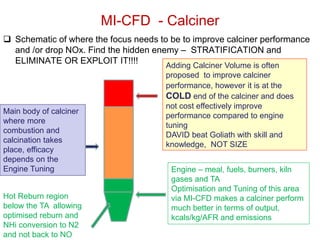

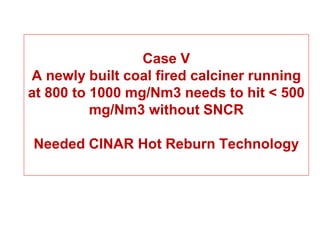

![Splitting Meal, Modifying Petcoke Burner and Injecting Alternative Fuels

T [oC]

Pink: SRF

O2 [kg/kg]

Black:

Petcoke

Purple:

BF 1

Hotspots at

cone and 60% Meal

cylinder mass

injected Yellow:

body

below TA BF 2

reduced by

better meal

calcination. AF´s falling to kiln hearth

should be avoided by

Av. Calcination: 88% insert installation in order

High temperatures to prevent build up

Petcoke Av. Burnout: 98%

caused by AF´s , formation .

dropping through SRF Av. Burnout: 95%

need a customised Bio Fuel 1 Av. Burnout: 86%

venturi Biofuel 2 Av. Burnout:90%](https://image.slidesharecdn.com/cemtechpaper-130308012036-phpapp02/85/100-High-S-petcoke-and-AFR-with-lt-500-mg-Nm3-NOx-31-320.jpg)

![NOx to 500 mg/Nm3

The simulation below shows a prediction for normal

operation that show the calciner NO generation to give a

calciner exit NOx of 850 ppm , with a reburn temperature max

< 1200oC;

NOx T [oC]

[ppm]

Coal injection

/Meal injection

@ 12 m (@ 0.5

secs) to TA

mixing

The reason it is not meeting 500 mg/Nm3 is that the reburn

temperature is too low for the 0.5 secs RT between the coal

injection and the TA mixing into the reburn zone

Dropping the burners by 3.5 m and optimizing them gets

1300C for 0.15 sec before meal and plus 0.5 before TA mixing](https://image.slidesharecdn.com/cemtechpaper-130308012036-phpapp02/85/100-High-S-petcoke-and-AFR-with-lt-500-mg-Nm3-NOx-34-320.jpg)