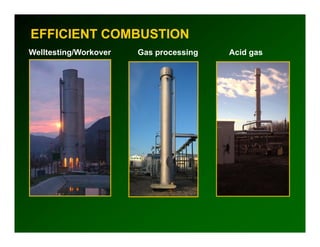

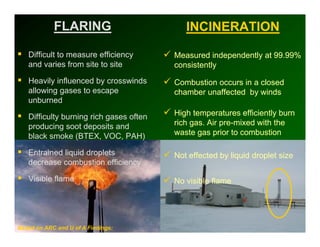

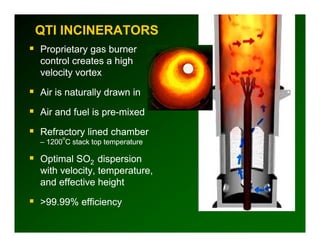

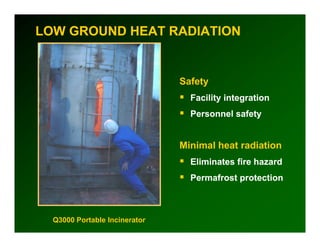

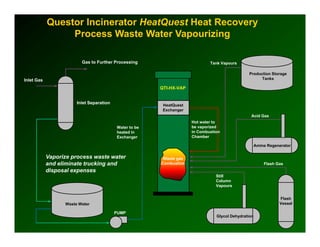

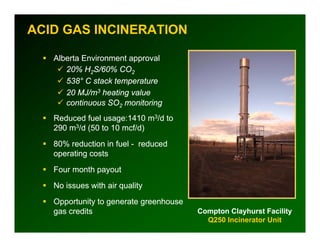

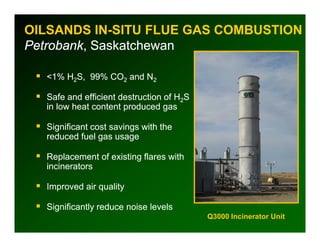

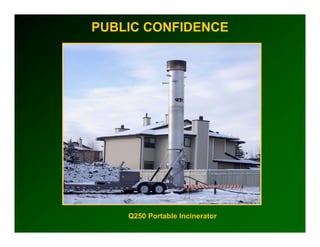

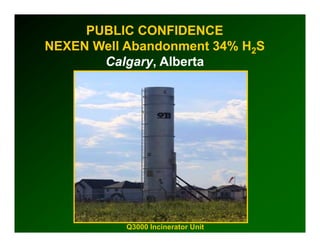

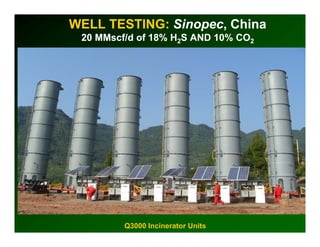

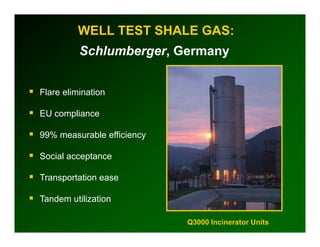

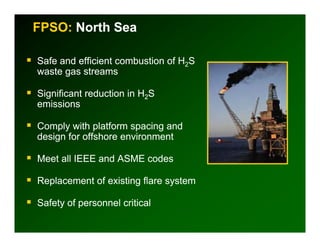

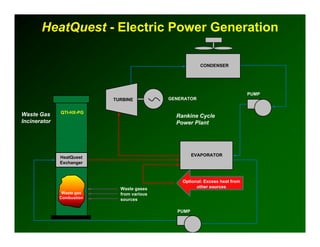

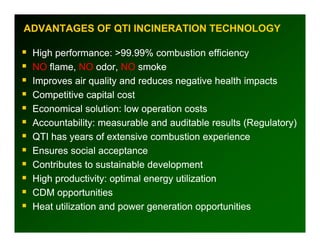

Questor Technology Inc. is an international environmental technology company that specializes in waste gas incineration solutions. Their products help clients operate cost effectively while protecting the environment and ensuring sustainable operations. Questor develops customized incineration systems that efficiently combust waste gases, improving air quality at a competitive cost.