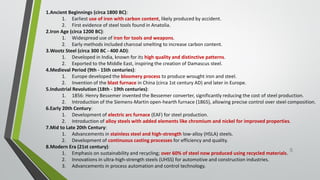

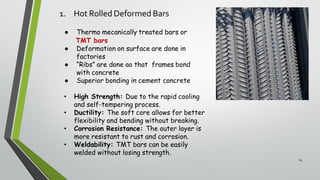

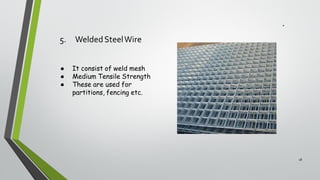

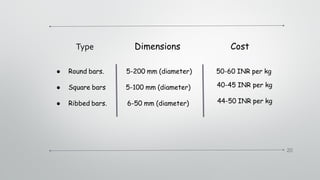

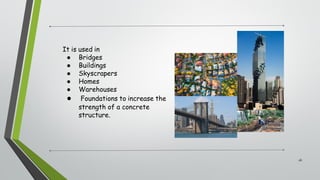

The document provides a comprehensive overview of steel, particularly reinforced steel, including its history, properties, types, and applications. It highlights the evolution of steel production techniques, the advantages of using reinforced steel in concrete construction, and its various grades and uses in modern engineering. Reinforced steel's high tensile strength and durability make it essential for structures like bridges, skyscrapers, and foundations.