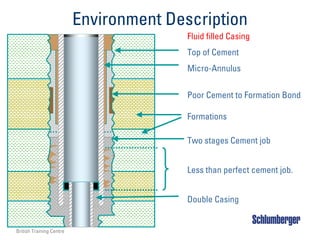

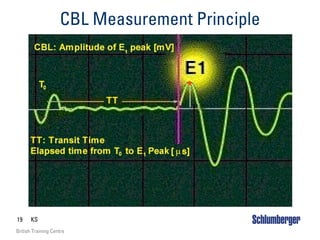

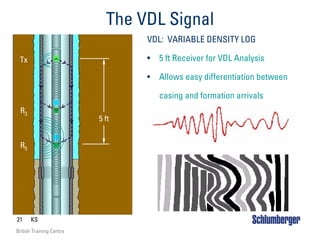

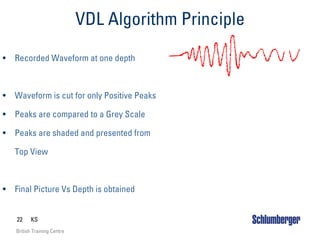

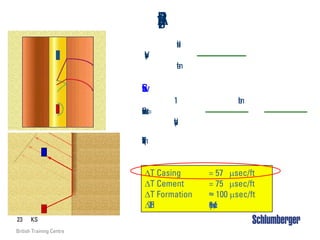

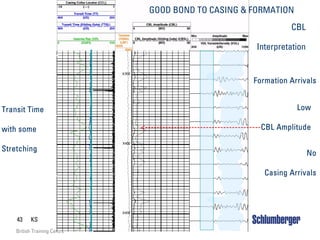

The document provides comprehensive information on Cement Bond Logging (CBL) and Variable Density Logging (VDL), focusing on the principles, measurement techniques, and interpretations crucial for assessing cement integrity and isolation in wellbore operations. It highlights the importance of factors like acoustic impedance, transit time, and amplitude in determining the quality of the cement bond. Additionally, it discusses common issues affecting measurements and their implications for cementing operations.

![2 KS

British Training Centre

Objectives of Primary Cementing

Casing

Zone Hydraulic Isolation

Oil Zone

Water Zone

Cement

Prevents

•Mixing of unwanted fluids

•Fluids escaping to surface

•Invading fluids [crossflow]

•Casing Corrosion

•Casing Collapse

Shale Zone

Gas Zone](https://image.slidesharecdn.com/05cblvdl-241130175401-2ad2eba8/85/CBL-VDL-Cement-Bond-Logging-Basic-Theory-Interpretation-2-320.jpg)

![3 KS

British Training Centre

Cement Quality Problems

Casing

No Zone Hydraulic Isolation

Oil Zone

Water Zone

Cement

Causes

•Mixing of unwanted fluids

•Fluids escaping to surface

•Invading fluids [crossflow]

•Casing Corrosion

•Casing Collapse](https://image.slidesharecdn.com/05cblvdl-241130175401-2ad2eba8/85/CBL-VDL-Cement-Bond-Logging-Basic-Theory-Interpretation-3-320.jpg)

![5 KS

British Training Centre

CBL-VDL Log Applications

Client Needs

Oil Zone

Water Zone

Cement

To Evaluate Cement Job

•Check Integrity of Cement

•To Verify Zone Isolation

•To Determine Cement

Strength

•Is there any Channel ?

•Is it necessary to Repair ?

•Will be possible to Repair?

[ by performing a SQUEEZE ]

•Where is the Top of the

Cement ?

Casing](https://image.slidesharecdn.com/05cblvdl-241130175401-2ad2eba8/85/CBL-VDL-Cement-Bond-Logging-Basic-Theory-Interpretation-5-320.jpg)

![8 KS

British Training Centre

Basic CBL Principle

Similar to a Ringing Bell

When Fluid is behind

Casing, pipe is free to

vibrate [ loud sound ]

When the casing is

bonded to hard cement,

casing vibrations are

attenuated proportionally

to bonded surface

Good

Bond

Good

Good

Bond

Bond

No

Cement

No

No

Cement

Cement](https://image.slidesharecdn.com/05cblvdl-241130175401-2ad2eba8/85/CBL-VDL-Cement-Bond-Logging-Basic-Theory-Interpretation-8-320.jpg)

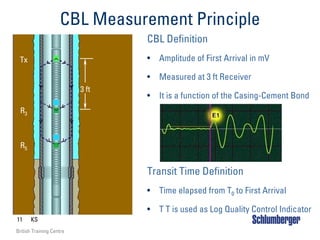

![12 KS

British Training Centre

CBL Qualitative Meaning

Good

Bond

Good

Good

Bond

Bond

No

Cement

No

No

Cement

Cement

HIGH CBL signal strength => pipe is free to vibrate [ no cement ]

LOW CBL signal strength => atennuated energy [ cement is present]](https://image.slidesharecdn.com/05cblvdl-241130175401-2ad2eba8/85/CBL-VDL-Cement-Bond-Logging-Basic-Theory-Interpretation-12-320.jpg)

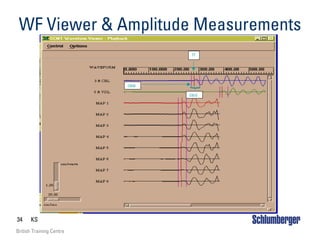

![28 KS

British Training Centre

CBL-VDL Standard Outputs Presentation

•Transit Time TT in micro-seconds [µs]

•CBL Amplitude in millivolts [mV ]

•VDL Variable Density Log [wafeform visual representation]

0 CBL 100

[mV]

400 TT 200

[µs]

200 VDL 1200

[µs]

GR

CCL](https://image.slidesharecdn.com/05cblvdl-241130175401-2ad2eba8/85/CBL-VDL-Cement-Bond-Logging-Basic-Theory-Interpretation-28-320.jpg)

![29 KS

British Training Centre

CBL-VDL Standard Outputs

•Transit Time TT in micro-seconds [µs]

Log Quality Control

•CBL Amplitude in millivolts [mV ]

Quantitative Measurement of waveform energy

•VDL Variable Density Log [waveform visual representation]

Qualitative Analysis of sound

Qualitative indicator of the presence of solid materials behind the casing

•Gamma Ray and CCL as auxiliary curves for Correlation](https://image.slidesharecdn.com/05cblvdl-241130175401-2ad2eba8/85/CBL-VDL-Cement-Bond-Logging-Basic-Theory-Interpretation-29-320.jpg)

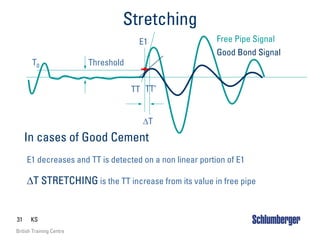

![32 KS

British Training Centre

TT Cycle Skipping

E1 could not reach Detection Threshold Level

T T skips to 3rd Peak [E3 ]........this is known as CYCLE SKIPPING

In cases of very Good Cement

Threshold

E1 E3

E2

T0

TT TT’](https://image.slidesharecdn.com/05cblvdl-241130175401-2ad2eba8/85/CBL-VDL-Cement-Bond-Logging-Basic-Theory-Interpretation-32-320.jpg)

![33 KS

British Training Centre

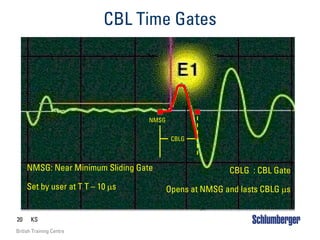

CBL Time Gates

E1 does not reach Detection Threshold Level

T T skips to 3rd Peak [E3 ]........this is known as CYCLE SKIPPING

Threshold

E3

T0

TT TT’](https://image.slidesharecdn.com/05cblvdl-241130175401-2ad2eba8/85/CBL-VDL-Cement-Bond-Logging-Basic-Theory-Interpretation-33-320.jpg)

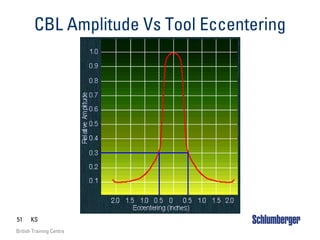

![48 KS

British Training Centre

Tool Eccentering

Causes for Eccentralization

5

3

2

T

• Improper Equipment selection

[ Centralizers ] for Casing Size

• Missing or Broken Centralizer(s)

• Weak Centralizers in deviated wells

• Tool Damaged and/or bent

• Damaged Casing

Consequences

• Unbalanced sound paths

• Resulting waveform is meaningless](https://image.slidesharecdn.com/05cblvdl-241130175401-2ad2eba8/85/CBL-VDL-Cement-Bond-Logging-Basic-Theory-Interpretation-48-320.jpg)

![49 KS

British Training Centre

Eccentering Analysis

There will be destructive interference from different sound paths

Waveform from close tool side to casing

If the tool is eccentered

Threshold

T0

TT

Short Path Waveform

Resulting Waveform

Waveform from far tool side to casing

Delayed Waveform

Result is a Bad Log

not recoverable

in Playback

Normal Waveform

Resulting waveform has Dramatic lower amplitude

Resembling a zone of Good Cement but with shorter Transit Time [≈ 4 µs less]](https://image.slidesharecdn.com/05cblvdl-241130175401-2ad2eba8/85/CBL-VDL-Cement-Bond-Logging-Basic-Theory-Interpretation-49-320.jpg)

![50 KS

British Training Centre

Eccentering

If the tool is eccentered

Threshold

T0

TT

Resulting Waveform Normal Waveform

There will be destructive interference from different sound paths

Waveform from close tool side to casing

Waveform from far tool side to casing

Result is a Bad Log

not recoverable

in Playback

Resulting waveform has Dramatic lower amplitude

Resembling a zone of Good Cement but with shorter Transit Time [≈ 4 µs less]](https://image.slidesharecdn.com/05cblvdl-241130175401-2ad2eba8/85/CBL-VDL-Cement-Bond-Logging-Basic-Theory-Interpretation-50-320.jpg)

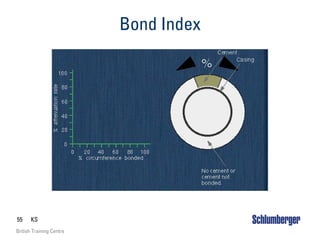

![54 KS

British Training Centre

CBL Quantitative Interpretation

• ATTENUATION

– Logarithm of E1 amplitude [first peak of CBL waveform]

• BOND INDEX

Attenuation in zone of interest [dB/ft]

BI =

Attenuation in Cemented Section [dB/ft]](https://image.slidesharecdn.com/05cblvdl-241130175401-2ad2eba8/85/CBL-VDL-Cement-Bond-Logging-Basic-Theory-Interpretation-54-320.jpg)

![56 KS

British Training Centre

Zone Insulation Based on Bond Index

5

5 6

6 7

7 8

8 9

9 10

10

30

30

25

25

20

20

15

15

10

10

5

5

Bond Index = 70 %

Bond Index = 70 %

Bond Index = 60 %

Bond Index = 60 %

Bond Index = 80 %

Bond Index = 80 %

C

a

s

i

n

g

O

.

D

.

[

i

n

]

I

n

t

e

r

v

a

l

[

f

t

]](https://image.slidesharecdn.com/05cblvdl-241130175401-2ad2eba8/85/CBL-VDL-Cement-Bond-Logging-Basic-Theory-Interpretation-56-320.jpg)

![5

7

K

S

B

r

i

t

i

s

h

T

r

a

i

n

i

n

g

C

e

n

t

r

e

C

B

L

Q

u

a

n

t

i

t

a

t

i

v

e

I

n

t

e

r

p

r

e

t

a

t

i

o

n

Q

u

a

n

t

i

t

a

t

i

v

e

I

n

t

e

r

p

r

e

t

a

t

i

o

n

I

n

t

e

r

p

r

e

t

a

t

i

o

n

M

1

C

h

a

r

t

C

a

s

i

n

g

D

a

t

a

O

.

D

.

7

”

,

2

9

l

b

m

/

f

t

C

e

m

e

n

t

C

o

m

p

r

e

s

i

v

e

S

t

r

e

n

g

t

h

3

0

0

0

p

s

i

C

a

s

i

n

g

T

h

i

c

k

n

e

s

s

[

f

r

o

m

t

a

b

l

e

s

]

.

4

0

8

i

n

C

B

L

v

a

l

u

e

f

o

r

1

0

0

%

B

o

n

d

[

m

i

n

i

m

u

m

e

x

p

e

c

t

e

d

a

m

p

l

i

t

u

d

e

]

7

0

%

B

o

n

d

I

n

d

e

x

?

C

B

L

v

a

l

u

e

f

o

r

7

0

%

B

o

n

d](https://image.slidesharecdn.com/05cblvdl-241130175401-2ad2eba8/85/CBL-VDL-Cement-Bond-Logging-Basic-Theory-Interpretation-57-320.jpg)