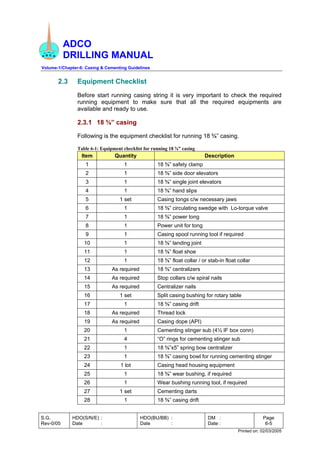

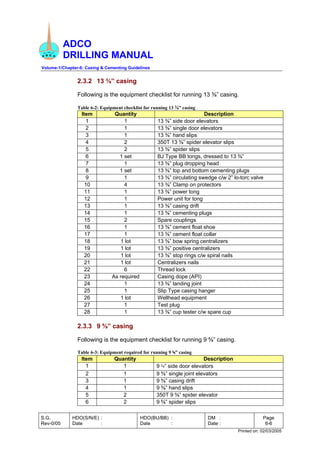

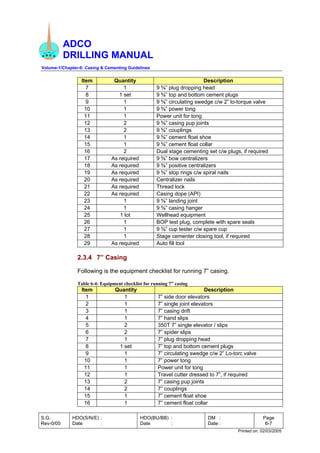

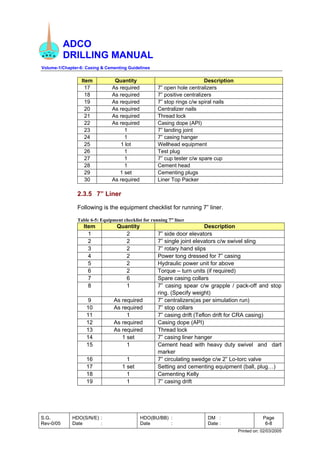

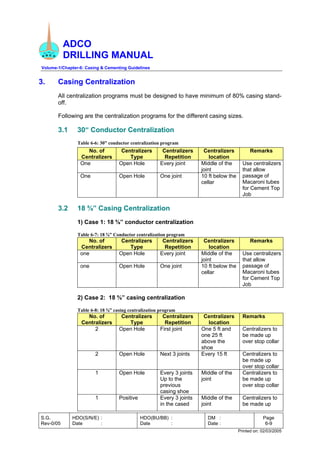

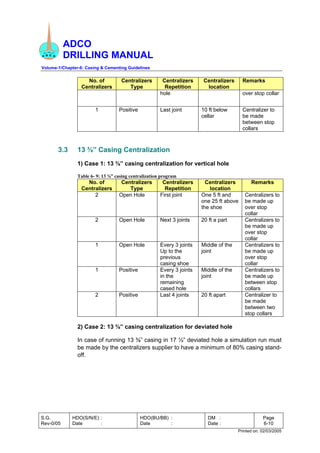

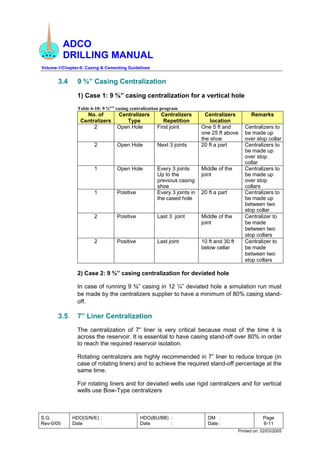

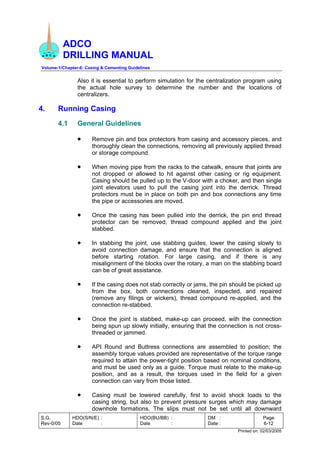

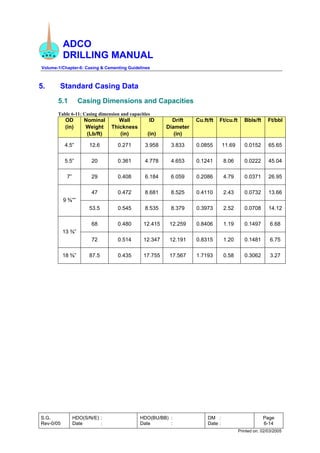

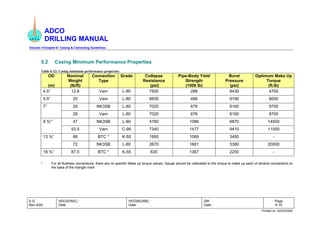

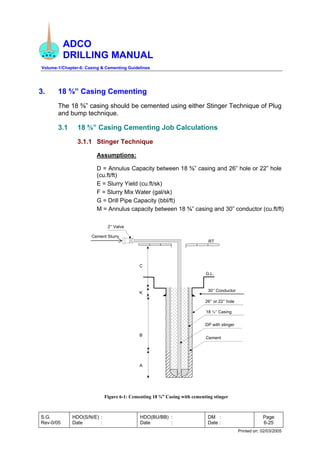

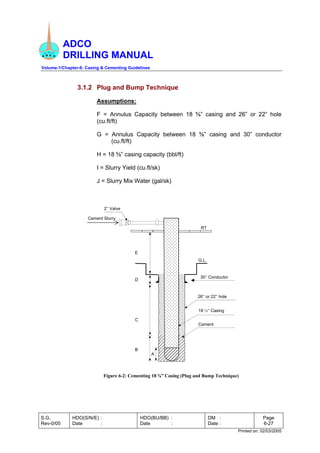

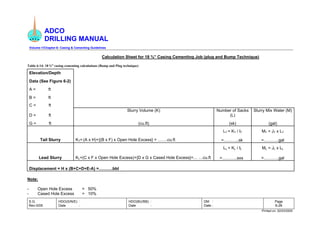

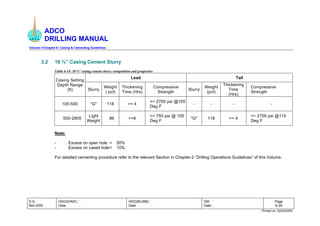

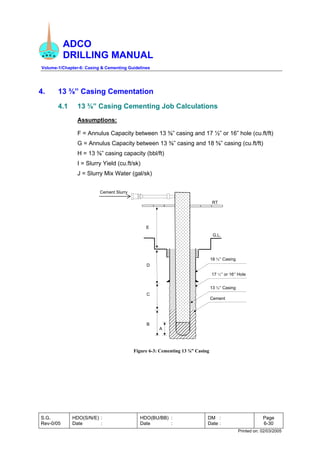

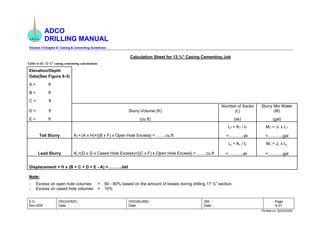

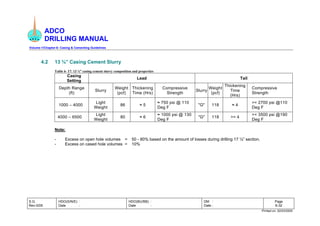

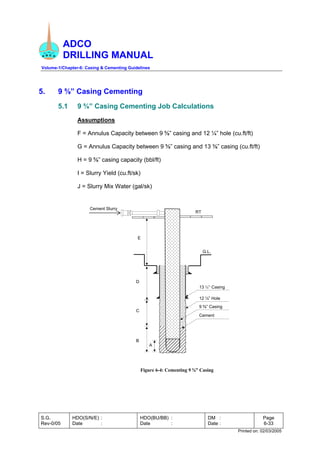

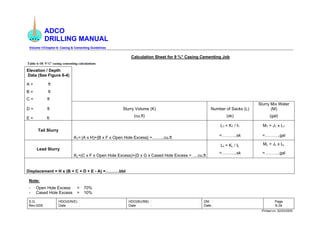

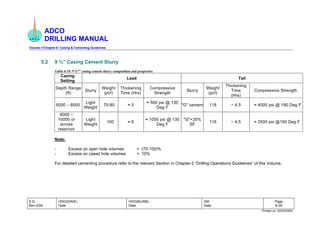

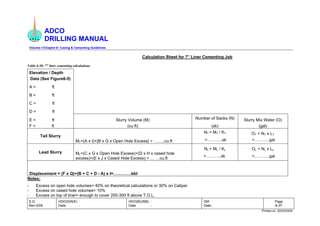

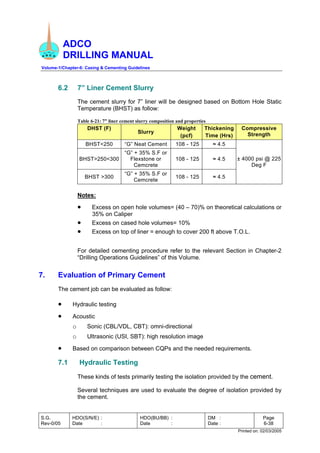

This document provides guidelines for casing handling, preparation, running and cementing from ADCO Drilling Manual Volume 1 Chapter 6. It details requirements for equipment, inspections, centralizers and procedures for running various casing sizes including 18 5/8", 13 3/8", 9 5/8" and 7" casing and liners. Standard data sheets are also included listing the equipment needed to run each casing string size. Cementing guidelines are provided covering requirements for different casing sizes.