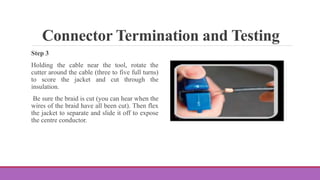

This document provides steps for properly preparing coaxial cable and terminating connectors for use in CCTV systems. It discusses that transmission media such as cable, connectors and installation methods account for over 65% of failures in CCTV systems. The document then provides 10 detailed steps for stripping cable, attaching connectors, testing connections, and labeling cables to help ensure optimal video quality and troubleshooting. Key steps include properly stripping cable, flaring the braid, crimping the connector, checking resistance values during testing, and labeling both ends of cables.