The document outlines the natural gas processing procedures essential for obtaining high-quality pipeline gas from crude natural gas. It details key steps including oil and condensate removal, water removal, sweetening to eliminate impurities like hydrogen sulfide and carbon dioxide, and various dehydration methods. The report emphasizes the importance of these processes in producing valuable byproducts and ensuring safe transportation of natural gas.

![Natural Gas Processing

10 | P a g e

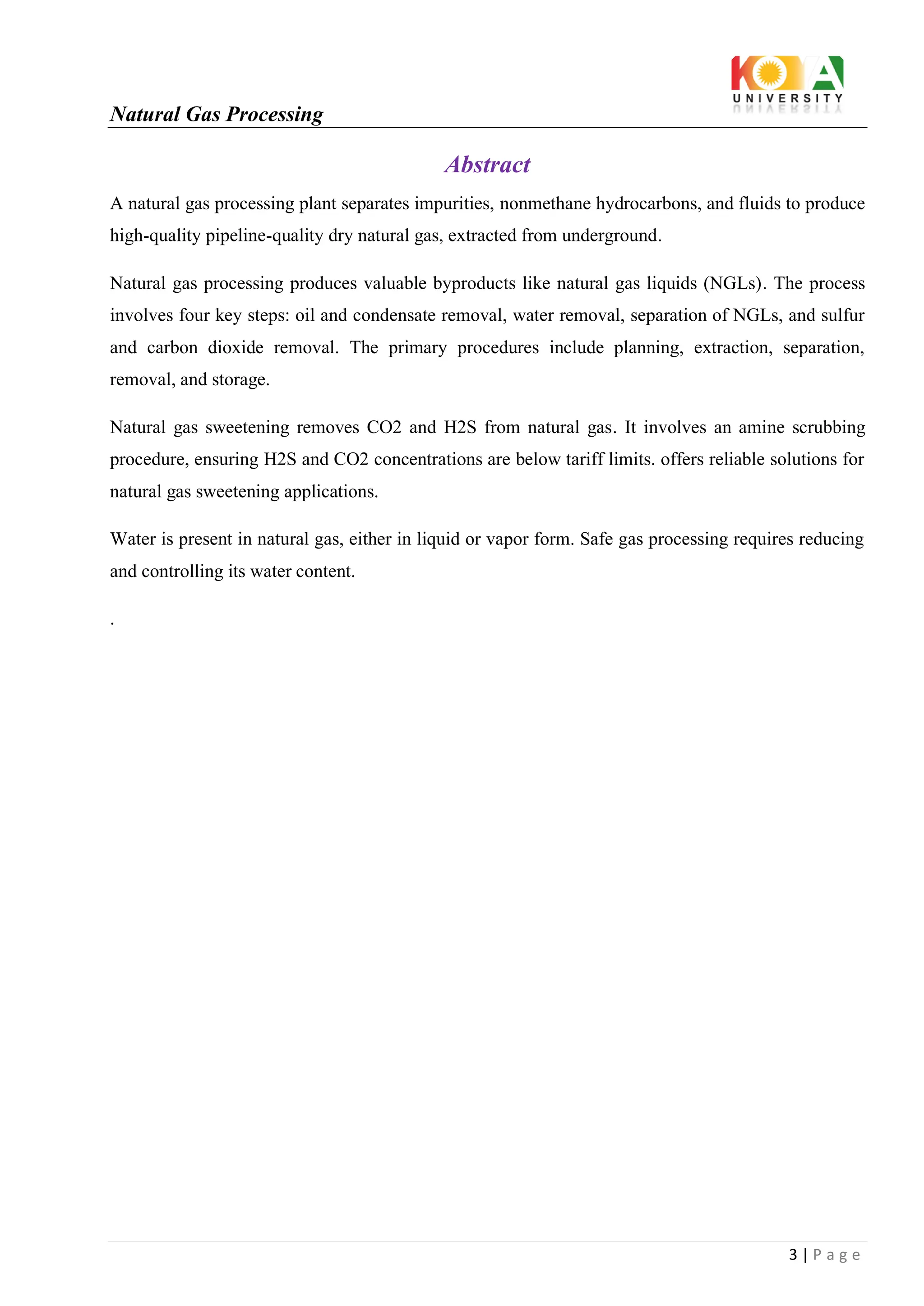

Discussion:

1. What is the first step in processing Natural gas reservoir?

a. The first step is separation, which divides the reservoir natural gas into water, oil, and

gas.

2. What is natural gas sweetening?

a. Natural gas sweetening is the process whereby [hydrogen sulfide (H2S) and carbon

dioxide (CO2)] are removed from the natural gas. Both [H2S and CO2] promote

corrosion through the formation of acids in the presence of water and can cause stress

cracking in the pipelines.

3. What are the methods for dehydrating natural gas commonly used?

a. The most typical ways for natural gas dehydration are (liquid desiccant (glycol)

dehydration and solid desiccant dehydration). These techniques are based on factors

like water content requirements, initial water content, and economic considerations.

4. Explain briefly the procces of natural gas compression?

a. The oil and gas industry uses two main types of compressors: reciprocating and

screw. A natural gas reciprocating compressor uses pistons and positive displacement

to compress the gas. Gas enters the manifold, flows into the compression cylinder,

then discharges at a higher pressure.](https://image.slidesharecdn.com/000-naturalgasprocessing-231219115056-a29a5d90/75/000-Natural-gas-processing-pdf-10-2048.jpg)

![Natural Gas Processing

12 | P a g e

References:

1. Speight, J. G. (2019). Recovery, storage, and transportation. Natural Gas, 149–186. Available at:

https://sci-hub.se/https://doi.org/10.1016/B978-0-12-809570-6.00005-9 [accessed: Oct./25/2023]

2. Mohammed Hamzah Msaed (2021). Natural Gas Processing, P3. Available at:

https://engineering.uodiyala.edu.iq/uploads/Departments2021/Chimecal%20Engineering/lect_2021/4/Nat

ural%20Gas%20Processing%20-%20Mohammed%20Hamzah%20Msaed.pdf [accessed: Oct./25/2023]

3. U.S. Department of Transportation (2017). Fact Sheet: Natural Gas Processing Plants.[online] Available

at:

https://primis.phmsa.dot.gov/comm/factsheets/fsnaturalgasprocessingplants.htm#:~:text=Associated%20h

ydrocarbons%2C%20known%20as%20'natural,%2C%20isobutane%2C%20and%20natural%20gasoline.

[accessed: Oct./25/2023]

4. Cameron p. Croft (2020). How Do You Process Natural Gas? Why Do We Process Natural Gas and

How? [online] Available at: https://www.croftsystems.net/oil-gas-blog/how-do-you-

processnaturalgas/#:~:text=Although%20natural%20gas%20processing%20has,oil%2C%20water%2C%2

0and%20condensates. [Accessed: Oct./25/2023]

5. energy insight (2023). Natural gas processing has many stages: extraction, removals, separation,

liquifying. The natural gas used in households is different in many ways from the extracted, raw natural

gas. [online] Available at: https://group.met.com/en/media/energy-

insight/naturalgasprocessing#:~:text=Natural%20gas%20processing%20has%20many,the%20extracted%

2C%20raw%20natural%20gas. [Accessed: Oct./25/2023]

6. Stewart, M. and Arnold, K., 2008. Gas-liquid and Liquid-liquid Separators. Gulf Professional

Publishing.p41-p43. Available at: file:///C:/Users/Kakon%20Soft/Downloads/Gas-Liquid-Liquid-Liquid-

Separators-Maurice-Stewart.pdf [Accessed: Oct./25/2023]

7. AMETEK (2023). Sweetening natural gas. [online] available at:

https://www.google.com/search?q=natural+gas+procces+natural+gas+sweetening&oq=natural+gas+proc

ces+natural+gas+sweetening&gs_lcrp=EgZjaHJvbWUyBggAEEUYOTIJCAEQIRgKGKABMgkIAhAh

GAoYoAEyCQgDECEYChigAdIBCTE0MTA4ajBqN6gCALACAA&sourceid=chrome&ie=UTF-8

[Accessed: Oct./25/2023]

8. Ahmed Mahmoud (2020). Process flow diagram for natural gas sweetening by absorption using

potassium carbonate solvent. [online image]. Available at: https://www.researchgate.net/figure/Process-

flow-diagram-for-natural-gas-sweetening-by-absorption-using-potassium-carbonate_fig1_341087000

[Accessed: Oct./25/2023]

9. Mokhatab, S. and Poe, W.A. (2012). Chapter 9 - Natural Gas Dehydration. [online] ScienceDirect.

Available at: https://www.sciencedirect.com/science/article/pii/B9780123869142000091) [Accessed 26

Oct. 2023].

10. Aisyah, R. (2018). Several Natural Gas Dehydration Methods and Range of Application. [online]

Chemical Engineering Portal. Available at:

https://missrifka.com/gas-processing-plant/several-natural-gas-dehydration-methods-and-range-of-

application.html [Accessed 26 Oct. 2023].

11. Archrock. (n.d.). What is Natural Gas Compression? [online] Available at:

https://www.archrock.com/what-is-natural-gas-

compression/#:~:text=Natural%20gas%20compression%20is%20an [Accessed 26 Oct. 2023].

12. Penn State Extension (2015). Understanding Natural Gas Compressor Stations. [online] Penn State

Extension. Available at: https://extension.psu.edu/understanding-natural-gas-compressor-stations.

13. Wanazelee W. Bakar, Rusmidah Ali (2010). Natural gas industry. Image (source: Energy Information

Administration, DOE). [online images] available at: Natural gas industry. Image (source: Energy Information

Administration,... | Download Scientific Diagram (researchgate.net) [ accessed: Oct./27/2023]](https://image.slidesharecdn.com/000-naturalgasprocessing-231219115056-a29a5d90/75/000-Natural-gas-processing-pdf-12-2048.jpg)