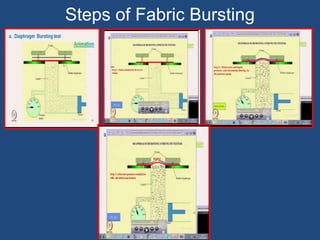

This document discusses bursting strength analysis, which tests the strength of fabrics in all directions simultaneously. Bursting strength is more suitable than tensile strength for fabrics without a clear warp/weft structure like knits, lace, and nonwovens. In a bursting strength test, liquid pressure is applied through a rubber diaphragm to bulge and stress a fabric sample in all directions until it bursts. The pressure at rupture is recorded. Proper sample size, clamping, and test speed are important for consistency. Burst strength indicates the lowest extension a fabric can withstand under multidirectional stress like at joints.