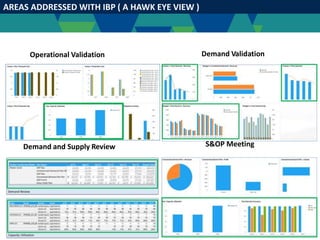

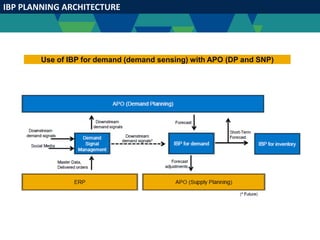

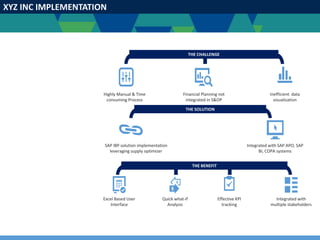

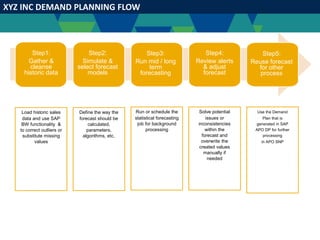

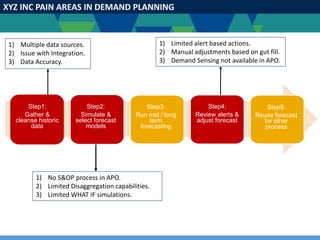

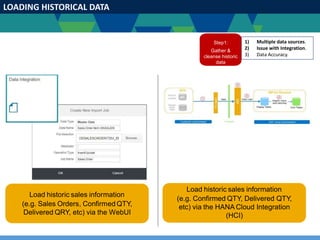

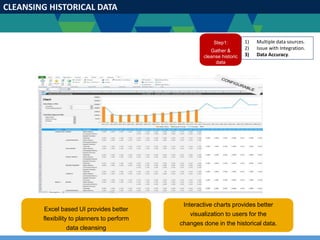

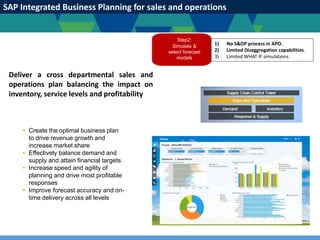

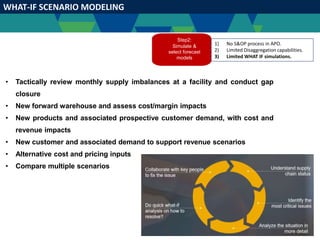

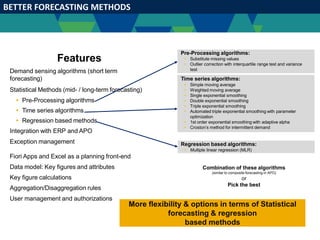

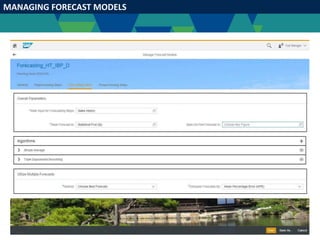

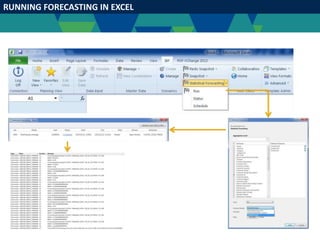

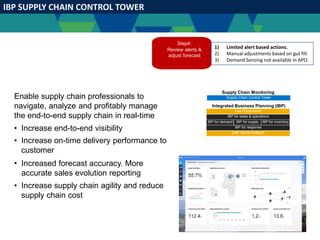

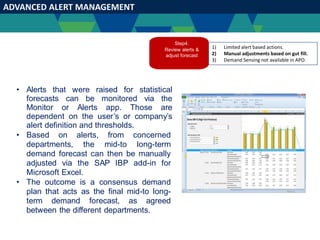

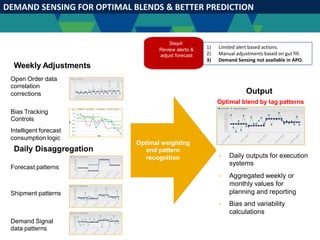

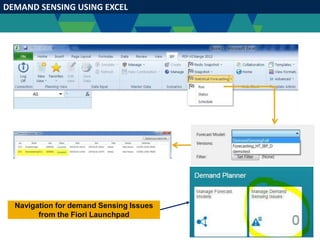

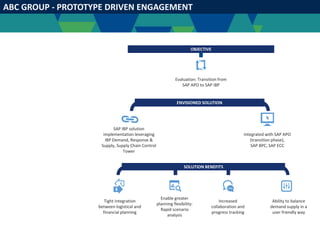

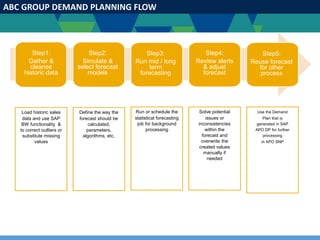

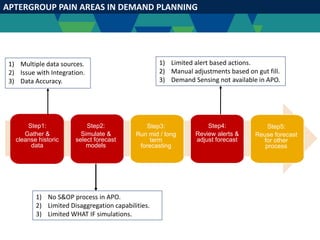

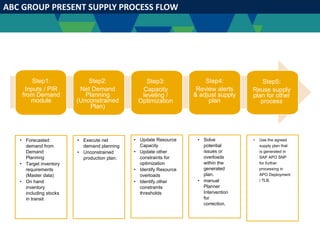

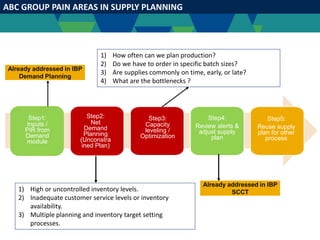

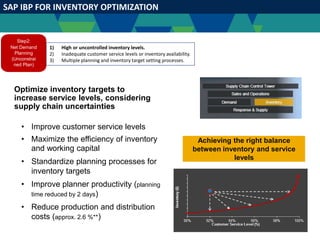

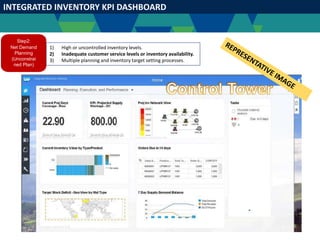

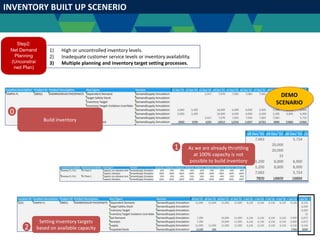

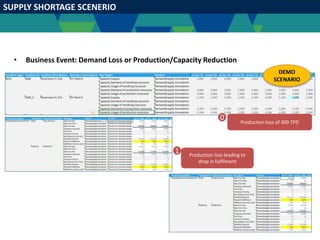

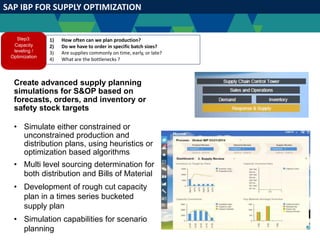

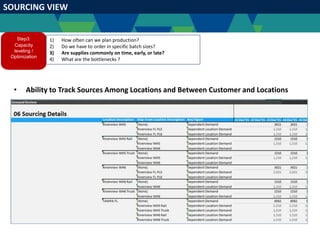

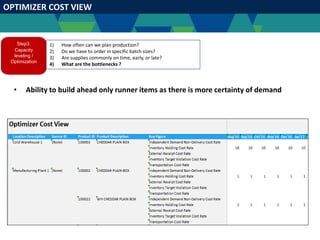

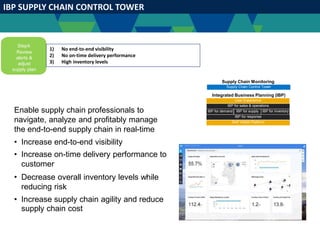

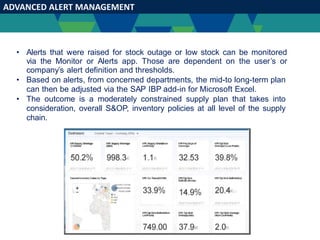

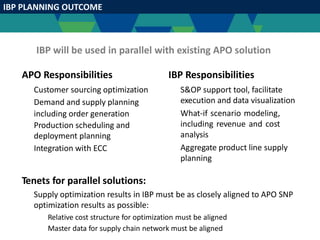

SAP IBP can address pain areas in demand and supply planning for ABC Group. IBP allows gathering and cleansing historic data from multiple sources. It offers improved forecasting methods like demand sensing and statistical algorithms. IBP enables what-if scenario modeling and integrated inventory KPI dashboards. Alerts can be better managed to adjust forecasts and plans. IBP provides supply optimization and a supply chain control tower for end-to-end visibility. IBP would be implemented in parallel with APO, with master data and optimization results closely aligned between the two systems.