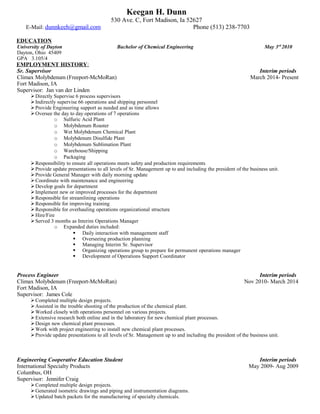

Keegan H. Dunn has over 10 years of experience in chemical engineering, including roles as a Sr. Supervisor and Process Engineer at Climax Molybdenum. He has a Bachelor's Degree in Chemical Engineering from the University of Dayton and has worked in cooperative education roles at International Specialty Products. Currently, Dunn is a Sr. Supervisor at Climax Molybdenum, where he oversees day-to-day operations and ensures safety and production requirements are met across multiple plants.