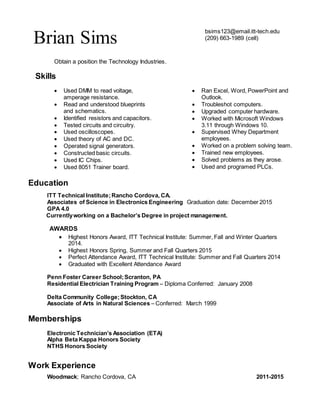

This resume is for Brian Sims, who seeks a position in the technology industry. He has an Associate's degree in Electronics Engineering and is working towards a Bachelor's degree in Project Management. His skills include circuit testing, computer hardware/software troubleshooting, and PLC programming. He has work experience as a manual machinist, electrician apprentice, and foreman in a dairy production facility. His objective is to obtain a technology position utilizing his education and experience in electronics, project management, and problem solving.