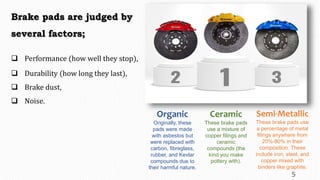

The document discusses various types of brake pads used in vehicles, highlighting their composition, performance, and suitability for different conditions. It categorizes brake pads into organic, ceramic, semi-metallic, and non-asbestos organic, detailing their advantages and disadvantages. Proper selection of brake pads is crucial for vehicle safety and performance, particularly in modifying cars.