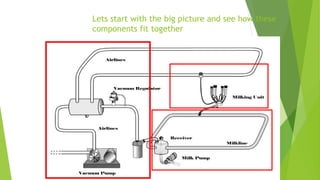

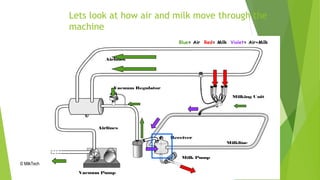

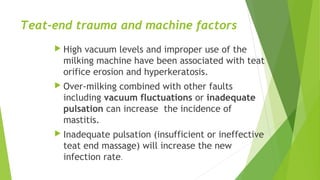

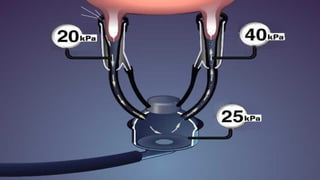

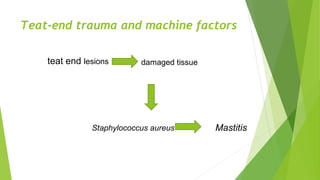

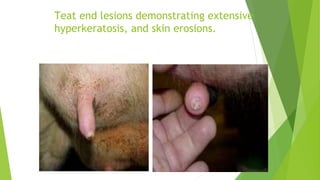

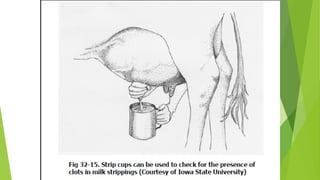

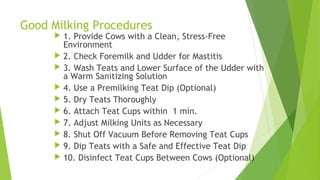

The document discusses standardized milking procedures for both hand milking and machine milking, outlining key steps to properly milk cows and ensure udder health such as cleaning the udder, using premilking dips, properly attaching and removing teat cups, and dipping teats after milking. It also examines how milking machines and hand milking can impact mastitis rates, discussing factors like teat end trauma, contamination risks, and machine maintenance.