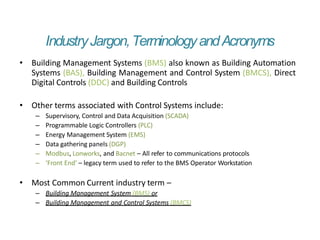

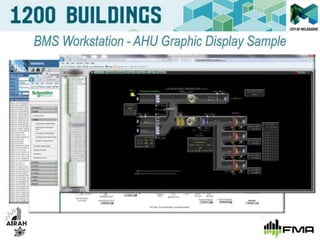

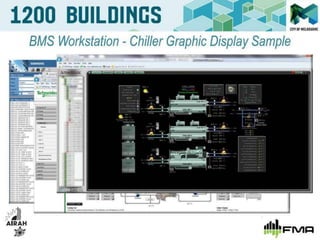

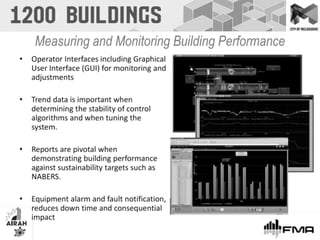

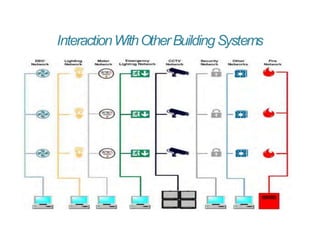

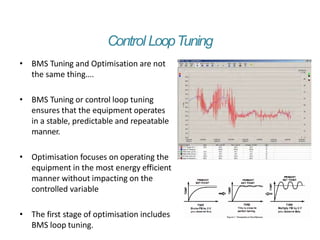

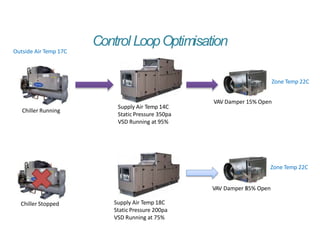

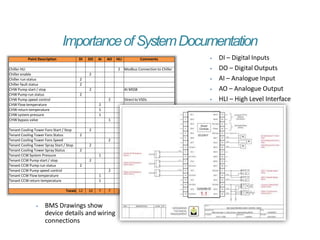

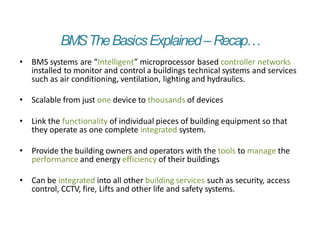

A Building Management System (BMS) controls and monitors a building's technical systems and services. It links individual equipment to operate as an integrated whole. Key benefits include improved tenant comfort, energy management to reduce costs, and tools to manage building ratings. Operational considerations include regular tuning, documentation, maintenance, and planning for the system lifecycle.