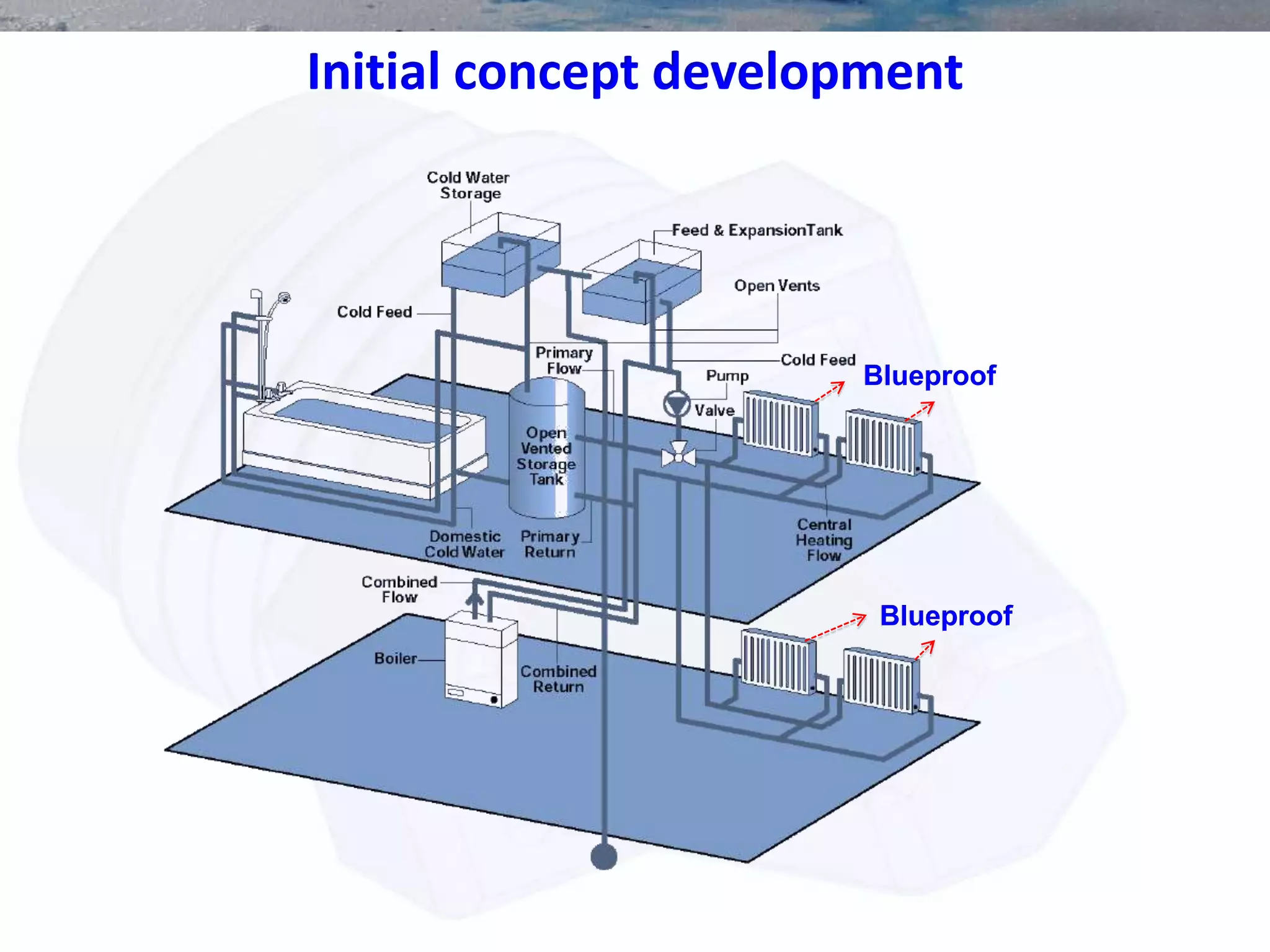

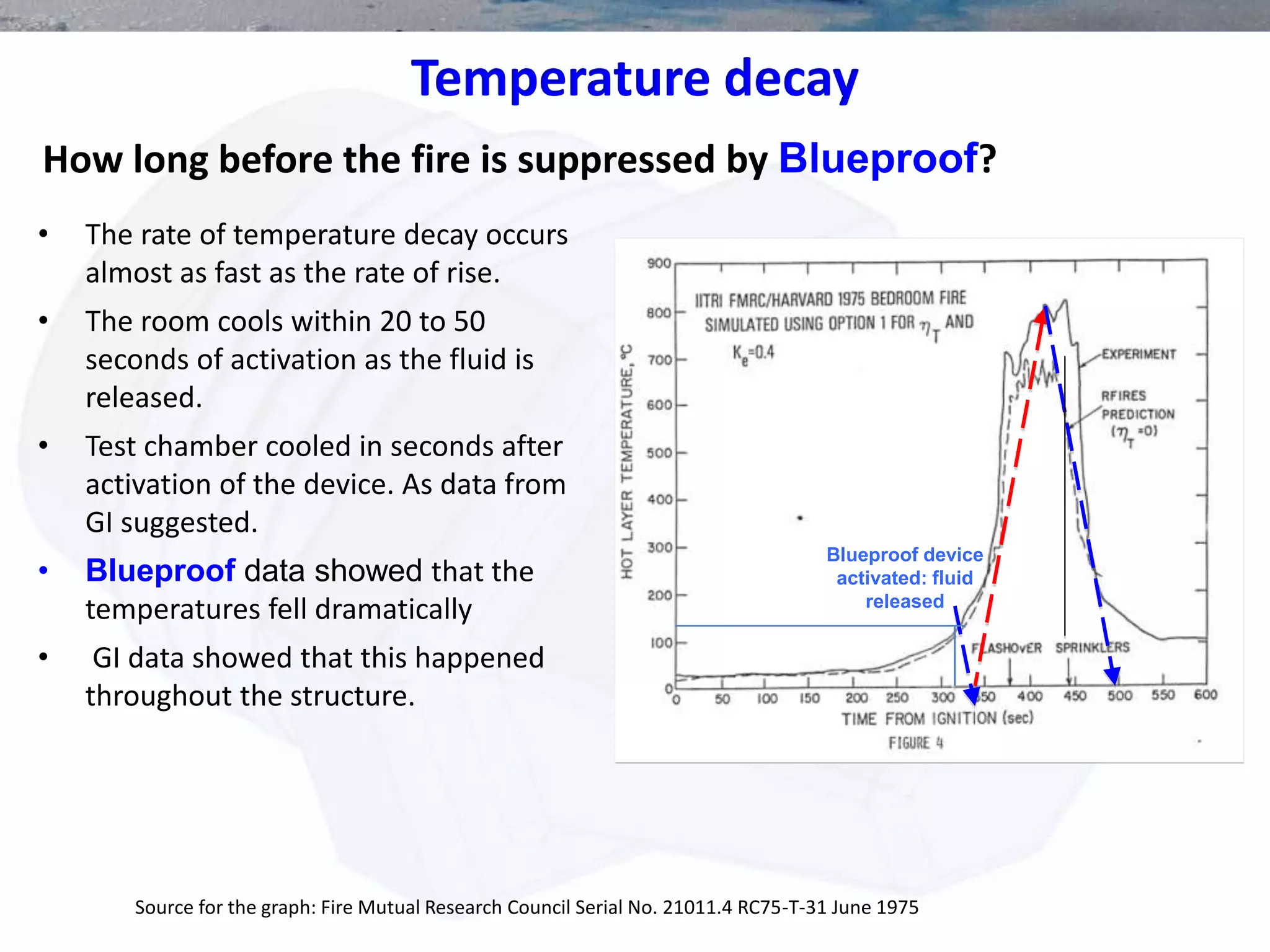

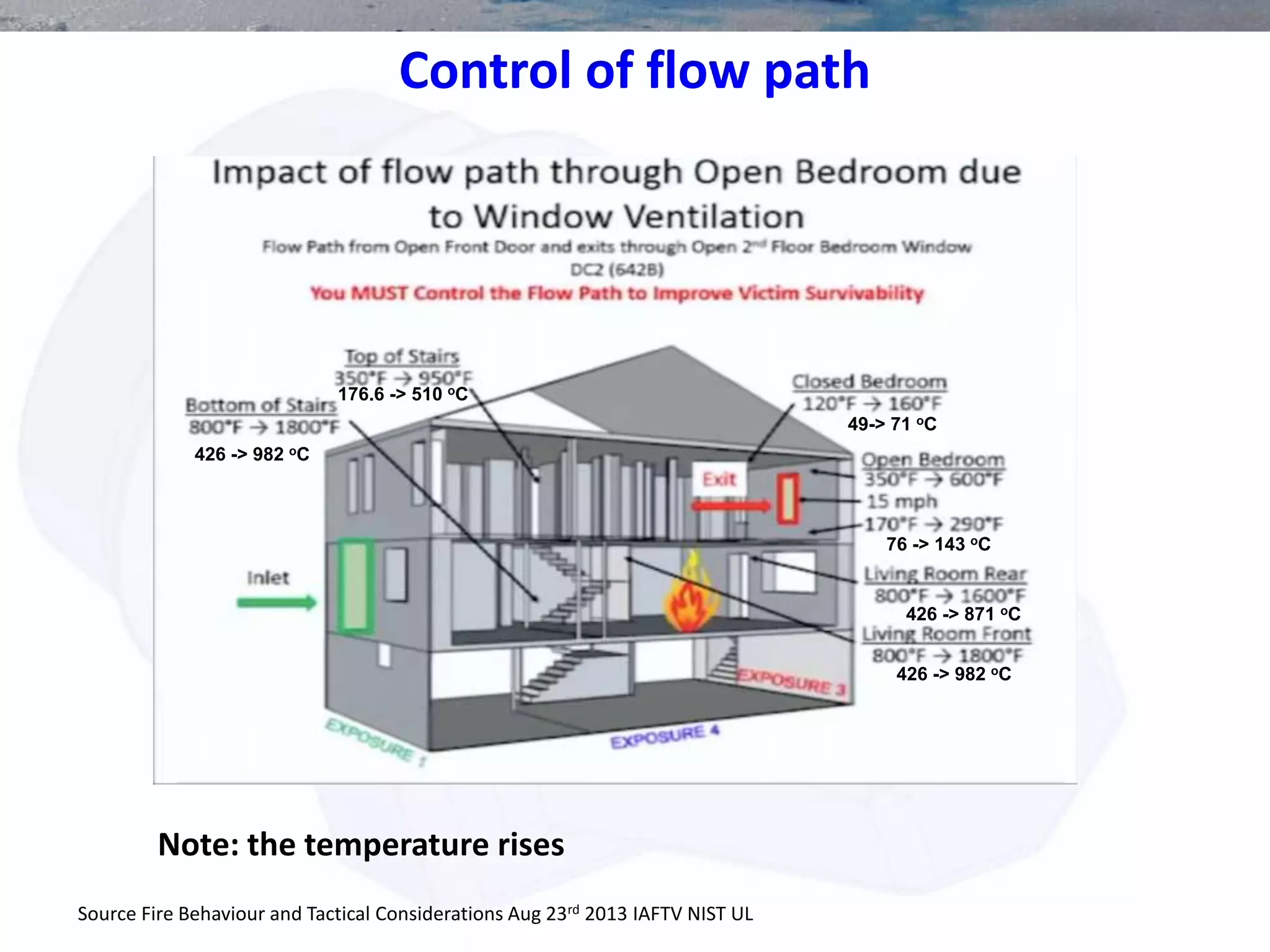

This presentation outlines the development and benefits of Blueproof, an innovative fire suppression device designed to protect both firefighters and civilians by targeting and cooling fire sources rapidly. The device has been proven to effectively reduce temperatures, stabilize oxygen levels, and improve survival rates during fires, with quick activation times that surpass traditional sprinkler systems. Overall, Blueproof aims to revolutionize fire safety by addressing the rapid onset of fires and reducing risks associated with smoke and flashovers.

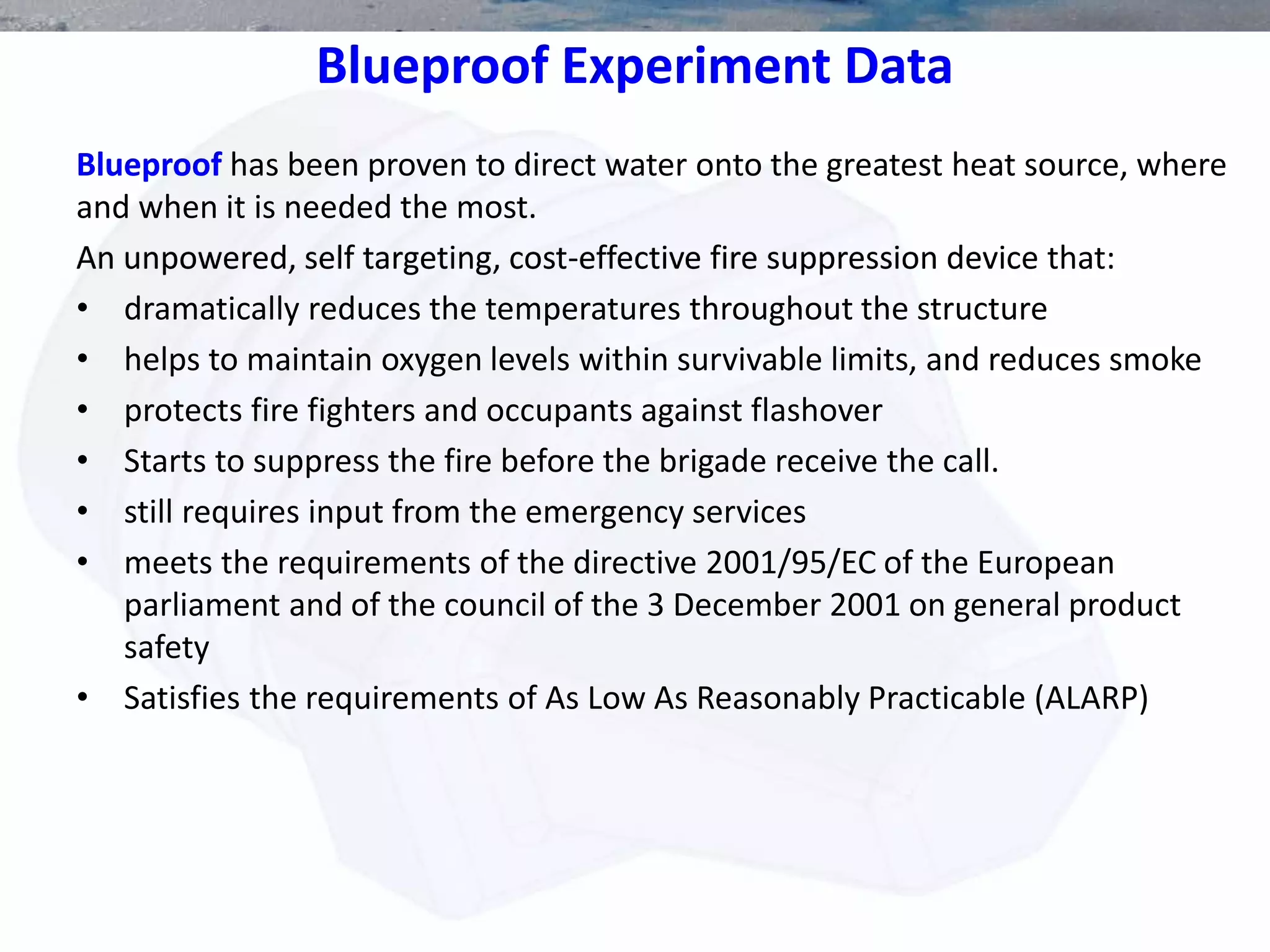

![Initial Concept Development

• very little water has a massive effect on a fire[1]

• the amount of fluid in a heating panel gives twice the requirement to

suppress a fire in an average sized room [2]

• a high tech device can be used to release the fluid from the heating panel

• the device will meet the temperature and pressure requirements of a

household radiator under normal operating conditions (13 bar and 75 oC

operating and 85 oC max )[3]

[1] Ref: Essentials of Fire Fighting and Fire Department Operations 5th Edition correlated to the 2008 edition of NFPA

1001.

[2] Ref The Case For Space Royal Institute for British Architects 2011

[3] Ref. Din EN 442

From the initial observations based on science that have been the inspiration

to GI and Bluerad’s design team, we know:](https://image.slidesharecdn.com/masterfeuulslidesin-140604063213-phpapp01/75/Blueproof-Update-to-FEU-May-2014-7-2048.jpg)

![Mode of Action

In a fire, the device releases the fluid in the heating panel into the room.

This happens when surface failure occurs along the lines of least resistance

[4] Spherulites embedded into a mosaic mesogen in the Maltese Cross pattern

The surface of Blueproof during

heat testing failing openWhy is this important?. Fluid flow and smoke

elimination.

Plastic Fails open in a Maltese Cross Pattern [4]](https://image.slidesharecdn.com/masterfeuulslidesin-140604063213-phpapp01/75/Blueproof-Update-to-FEU-May-2014-8-2048.jpg)

![Surface design

We designed bursting discs, a form of Pressure Safety Valve (PSV)

designed to code [5]

[5] American Society of Mechanical Engineers (ASME)

A fire tested sample

displaying how the thinned

wall section formed a

nozzle

Thinned wall bursting disc

sections](https://image.slidesharecdn.com/masterfeuulslidesin-140604063213-phpapp01/75/Blueproof-Update-to-FEU-May-2014-9-2048.jpg)

![Fire Testing

Tunnel Test experiments on Blueproof device

• confirmed activation time (avg. 44 seconds), way below the bench mark of

90 seconds for sprinkler in accordance to Code [6]

During full scale experiment with flame impingement [7]

• The device operated in all directions off five facets. It targeted the flames

This was unexpected as the device

targeted the flames 5 distinct

jets formed

[6] ASTM E84, NFPA 255, UL 723 and ULC S102

[7] ISO 5660-1-2002 Reaction to fire tests. Heat release, smoke production and mass loss rate. Part 1: Heat release

rate (Cone calorimeter method) International Organisation of standardization Geneva. 2002](https://image.slidesharecdn.com/masterfeuulslidesin-140604063213-phpapp01/75/Blueproof-Update-to-FEU-May-2014-10-2048.jpg)

![Fire Testing

During full scale experiment without flame impingement [8]

• The device activated on the uppermost facet as the heat radiated down

from the ceiling

[8] ISO TC 021/SC 05 Fire Protection – Automatic Sprinkler Systems –

Part 13: Requirements and test methods for extended coverage sprinklers 14-06-2013](https://image.slidesharecdn.com/masterfeuulslidesin-140604063213-phpapp01/75/Blueproof-Update-to-FEU-May-2014-11-2048.jpg)

![Integrity during fire

Did Blueproof melt?

• The air trapped at the top of the heating panel was forced through the

surface of the device during the Vicat (softening) phase

• Fluid passed through the device, it cooled and maintained its integrity.

• During full-scale fire experiments. Blueproofs retained their integrity as

shown below

All the above devices were subjected to direct flame impingement

on the test rig [7].

Device subjected to full

scale fire test displays

similar behaviour](https://image.slidesharecdn.com/masterfeuulslidesin-140604063213-phpapp01/75/Blueproof-Update-to-FEU-May-2014-12-2048.jpg)

![Direct flame impingement

Typical spray patterns during activation

with flame impingement [7]

Heat flux equivalent to one upholstered chair. Enough energy to create flashover.](https://image.slidesharecdn.com/masterfeuulslidesin-140604063213-phpapp01/75/Blueproof-Update-to-FEU-May-2014-13-2048.jpg)

![Blueproof full scale fire experiment

Accelerant added Fire started Fire suppressed by 5 distinct streams

created during experiment

Crib to ISO [8]

Blueproof head location

As per ISO [8] for a sidewall

mounted sprinkler head

Pressure incresed in heating

panel from 1.5 to over 9 bars

in seconds](https://image.slidesharecdn.com/masterfeuulslidesin-140604063213-phpapp01/75/Blueproof-Update-to-FEU-May-2014-20-2048.jpg)

![Water usage

Blueproof creates a cyclonic fog pattern. It does not entrain air to feed the fire

during interruption to flow. This contrasts with a fire fighter who may break

contact with the target due to manual handling errors and hence entrain air

when using a hose remotely.

Typical Blueproof

fog pattern at 3.5 bar [7]

In the full-scale fire

experiments

the pressure in the

heating panel increased to

over 9 bar in seconds and

forced the water from

the panel [8]](https://image.slidesharecdn.com/masterfeuulslidesin-140604063213-phpapp01/75/Blueproof-Update-to-FEU-May-2014-22-2048.jpg)

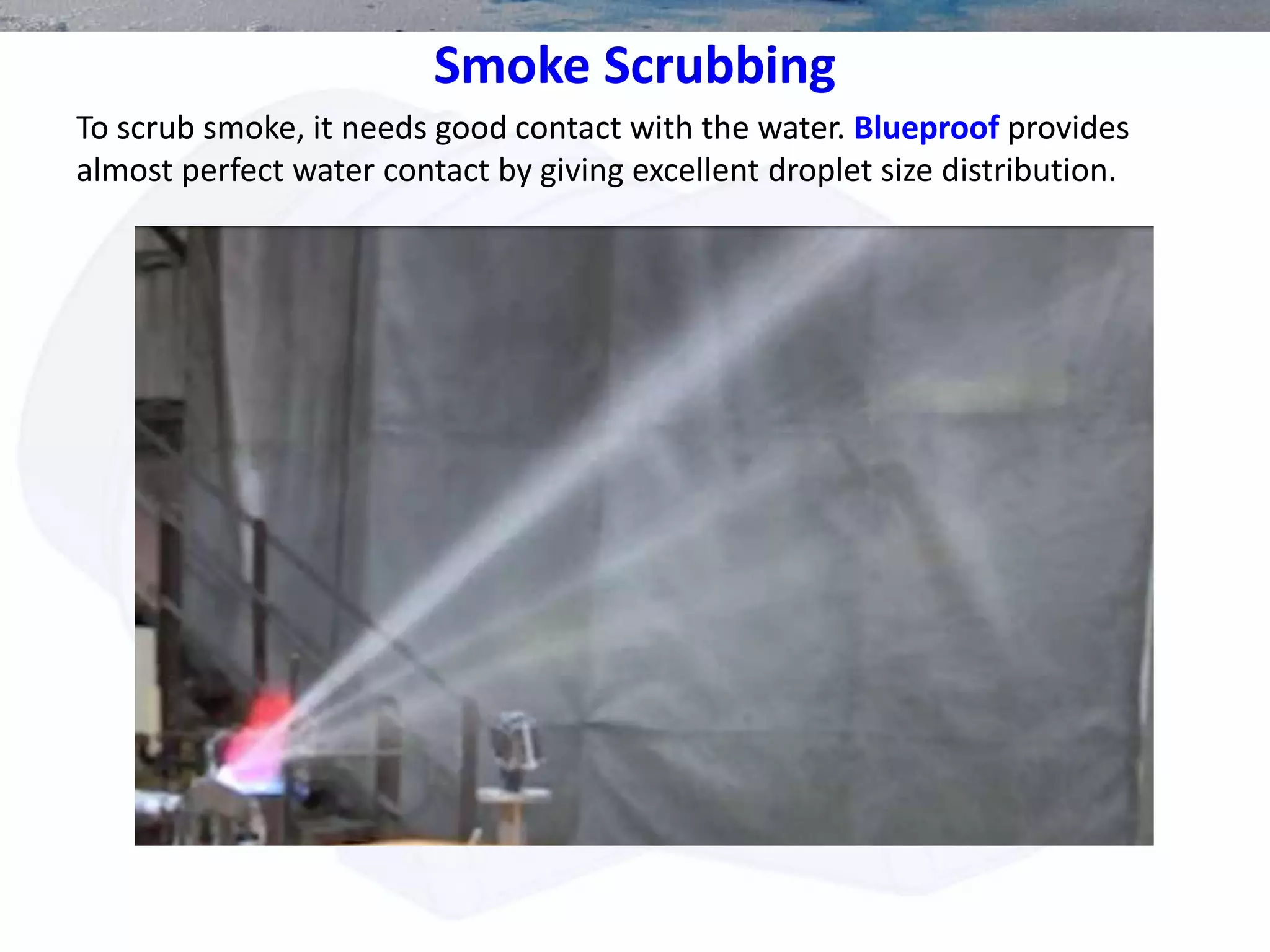

![Smoke scrubbing

Blueproof removed the smoke efficiently.

The device swirls the fluid flow and breaks up droplets by causing collisions.

This was shown in slide 8.

Cyclonic action and addition of steam produces a five fold increase in particulate removal.

99.9% smoke removal is possible using a steam venturi at 3.5 bar [8]

Blueproof by design is a venturi

The Venturi effect [9] is a jet effect; as with a funnel the velocity of the fluid increases as the

cross sectional area decreases, with the static pressure correspondingly decreasing.

According to the laws governing fluid dynamics, a fluid's velocity must increase as it passes

through a constriction to satisfy the principle of continuity,

Source: Spraying Systems Co

[8] Semrau et al , 1955.

[9] ‘The Venturi effect’ Wolfram Demonstrations Project.](https://image.slidesharecdn.com/masterfeuulslidesin-140604063213-phpapp01/75/Blueproof-Update-to-FEU-May-2014-29-2048.jpg)

![Impact on building occupants

• Fire suppression from the interior at the onset with Blueproof massively

increases the potential survival time! Oxygen levels stabilized above

breathable limits!

• Smoke concentration falls as the oxygen concentrations stabilize.

• Potential survival times need to be determined

• Unfortunately smoldering has not been studied to the same extent as

flaming and there is a lack of quantitative guidelines [10]

• During a smoldering fire the device will activate. The time taken for this

needs to be determined as it can take between 22 and 306 minutes for a

bed to flame [11]

[11 ] V.Babrauskas and J.Kransky, ‘Upholstered Furniture Transition from Smoldering to

Flaming’ Journal of Forensic Science, Nov. pp 1029-1031 (1997)

[10 ] Section Two, Chapter 9, Smoldering Combustion, T.J. Ohlemiller Fire Dynamics](https://image.slidesharecdn.com/masterfeuulslidesin-140604063213-phpapp01/75/Blueproof-Update-to-FEU-May-2014-34-2048.jpg)