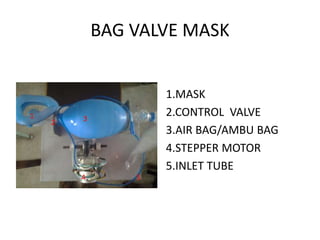

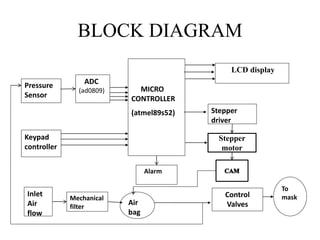

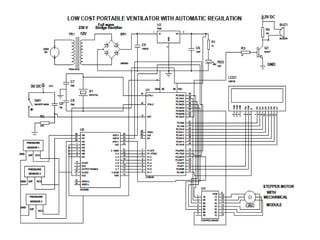

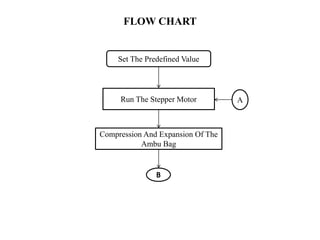

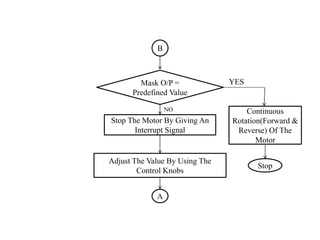

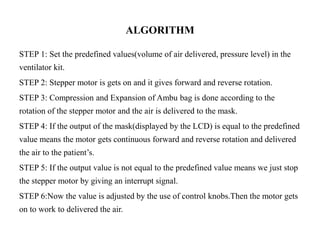

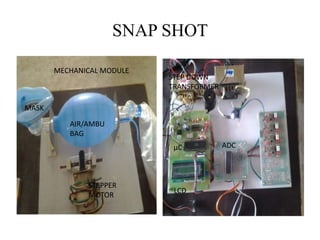

This document describes a proposed low-cost portable ventilator system that uses atmospheric air and an automated process to compress and expand an ambu bag to ventilate patients. The system uses a stepper motor controlled by a microcontroller to mechanically compress and expand the ambu bag, eliminating the need for manual operation. It can help prevent over-pressurizing of the lungs compared to manual ventilation methods. The proposed portable ventilator would be low-cost, easy to use in emergencies, and not require external oxygen cylinders.