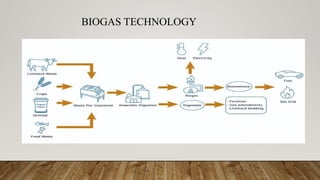

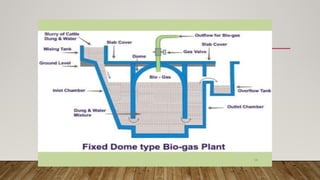

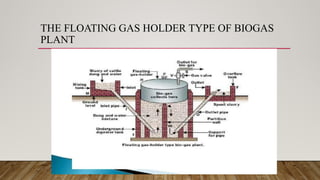

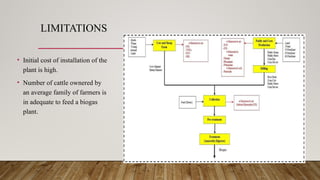

The document discusses biogas technology, emphasizing its potential as a renewable energy source derived from organic waste through anaerobic digestion. It covers the production methods, advantages, and limitations of biogas plants, as well as the properties and applications of biogas. The document also highlights recent developments and the importance of support from governments and organizations to promote biogas adoption.