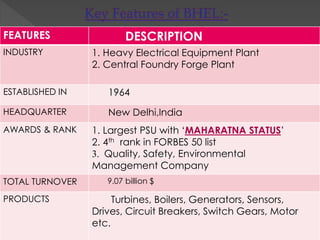

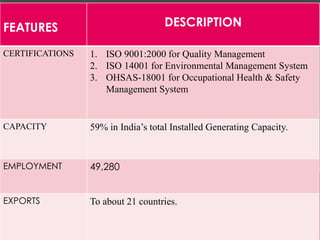

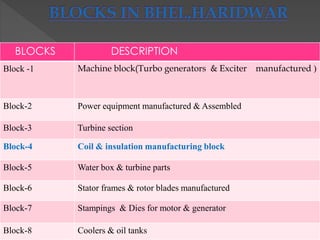

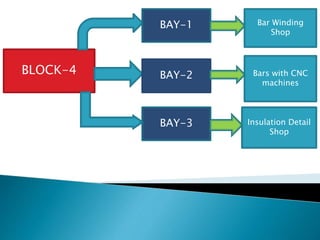

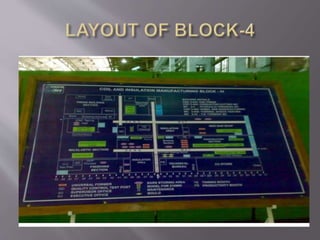

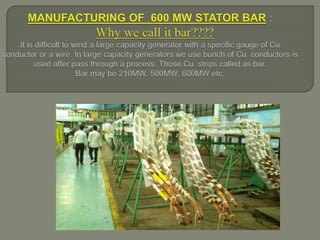

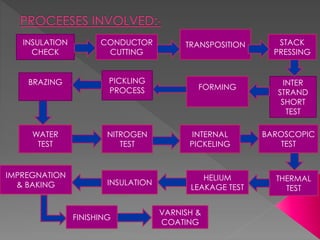

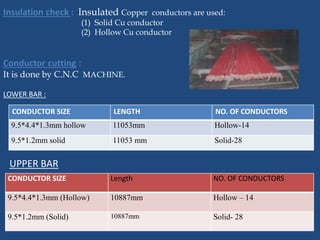

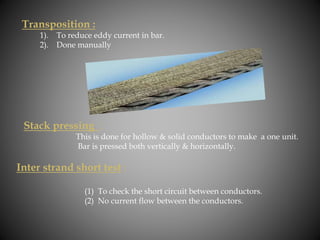

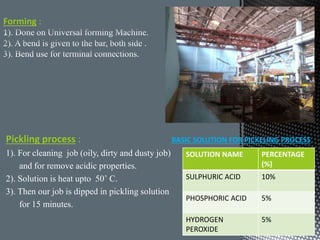

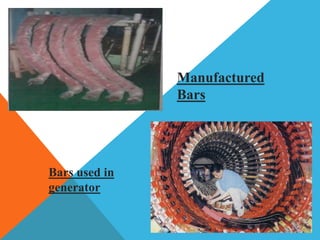

BHEL is India's largest power equipment manufacturer. It has several manufacturing blocks, including Block 4 which produces stator bars for generators. The stator bars undergo a multi-step manufacturing process that includes conductor cutting, transposition, stacking, brazing, various tests like water, nitrogen and thermal shock, insulation, varnishing and finishing. The finished bars are then used in power generators manufactured by BHEL.