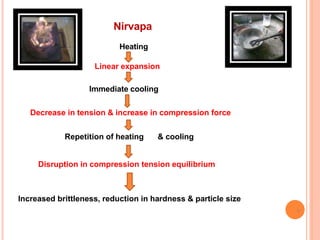

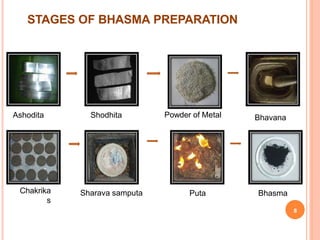

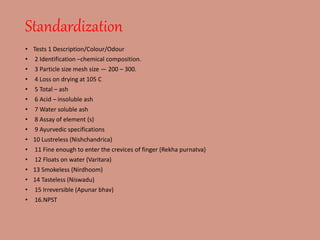

The document discusses Bhasma, a unique Ayurvedic preparation where metals or minerals are treated with herbal juices or decoctions to make them into fine particles. There are three key steps to creating a Bhasma: Shodhana for purification, Bhavana involving wet grinding, and Marana which uses incineration to further reduce particle size. The Marana process, with repeated heating and cooling, converts the materials into a fine powder with desirable properties for therapeutic use. Properly prepared Bhasma has characteristics like being fine enough to enter finger crevices, floating on water, and not reversing back into its original form after preparation.