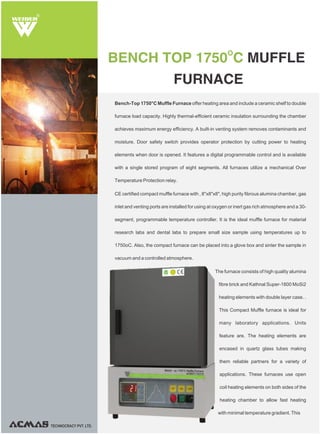

This document summarizes a benchtop 1750°C muffle furnace. It features a digital programmable controller, ceramic insulation for high energy efficiency, and safety features like a door switch. The furnace has a 8"x8"x8" chamber that can heat to 1750°C and includes a ceramic shelf. It is suitable for laboratory applications requiring controlled high temperature heating.