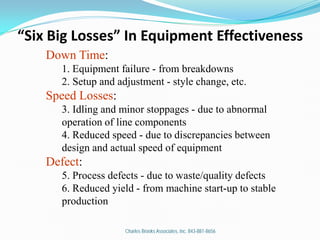

The document provides information on benchmarking and achieving world-class maintenance performance. It discusses benchmarking key performance indicators such as planned maintenance work percentage. World-class maintenance is characterized as being proactive, having clear vision and goals, and top management support. Direct maintenance costs are minimized by focusing on planned rather than breakdown work. Indirect costs from downtime are also reduced.