Basics of Gears.pdf

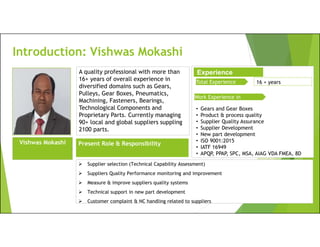

- 1. Introduction: Vishwas Mokashi Total Experience 16 + years Supplier selection (Technical Capability Assessment) Suppliers Quality Performance monitoring and improvement Measure & improve suppliers quality systems Technical support in new part development Customer complaint & NC handling related to suppliers A quality professional with more than 16+ years of overall experience in diversified domains such as Gears, Pulleys, Gear Boxes, Pneumatics, Machining, Fasteners, Bearings, Technological Components and Proprietary Parts. Currently managing 90+ local and global suppliers suppling 2100 parts. Vishwas Mokashi Experience Work Experience in • Gears and Gear Boxes • Product & process quality • Supplier Quality Assurance • Supplier Development • New part development • ISO 9001:2015 • IATF 16949 • APQP, PPAP, SPC, MSA, AIAG VDA FMEA, 8D Present Role & Responsibility

- 2. Basics of Gears, 03/2023, Vishwas Mokashi Basics of Gears

- 3. Topics: Basics of Gears, 03/2023, Vishwas Mokashi Mechanical Drives What is Gear Classification of Gears Types of Gears Nomenclature of Gear Working Gear Nomenclature Gear Manufacturing processes Process flow of Gear Gear Accuracy Gear Metrology Terms in lead and profile graph

- 4. Mechanical Drives: Basics of Gears, 03/2023, Vishwas Mokashi The mechanisms which are used to transmit the required motion and power from one shaft to another shaft are called mechanical drives. Types of Mechanical Drives: 1. Belt and rope drives 2. Chain drives 3. Gear drives These three power train elements transfer energy through rotary motion. Change the speed of rotation Change the direction of rotation Change the amount of torque available to do work.

- 5. We all know gears? Basics of Gears, 03/2023, Vishwas Mokashi A gear can be defined as the mechanical element used for transmitting power and rotary motion from one shaft to another by means of progressive engagement of projections called teeth. Advantages of Gear drives: Compact as compare to belt or chain. Transmit higher power and speed as compare to belt or chain. Transmit power between shafts which are parallel / non-parallel, intersecting / non-intersecting. Used for wide range of speed ratios.

- 6. Classification of Gears: Basics of Gears, 03/2023, Vishwas Mokashi Gears can be broadly classified by looking at the positions of axes such as parallel shafts, intersecting shafts and non-intersecting shafts. Power Transmit in PARALLEL SHAFT Spur Gear Helical Gear Power Transmit in two INTERSECTING SHAFT Bevel Gear • Straight Bevel Gear • Spiral Bevel Gear Power Transmit in NON PARALLEL and NON INTERSECTING SHAFT Worm and worm Gear

- 7. Types of Gears: Basics of Gears, 03/2023, Vishwas Mokashi Spur Gear: Teeth are straight and parallel to the gear shaft axis. transmits motion between parallel shafts. Helical Gear: Teeth are inclined to the axis of rotation, the angle provides more gradual engagement of the teeth during meshing, transmits motion between parallel shafts. Rack & Pinion: Rack and pinion is type of spur gear.

- 8. Types of Gears: Basics of Gears, 03/2023, Vishwas Mokashi Bevel Gear: Gears that mesh at an angle, usually 90° Changes the direction of rotation Shafts of the gear and pinion can intersect at 90°or any desired angle. Straight Bevel Gear Spiral Bevel Gear Worm and Worm Gear: Use for high velocity ratio (up to 300:1). The worm only be driving element.

- 9. Nomenclature of Gear: Basics of Gears, 03/2023, Vishwas Mokashi

- 10. Nomenclature of Gear: Basics of Gears, 03/2023, Vishwas Mokashi Pitch Circle : It is an imaginary circle which by pure rolling action would transmit same motion as the actual gear. Pitch Circle Diameter(d) : It is diameter of pitch circle. Module : It is ratio of pitch circle in mm to number of teeth. Addendum (ha) : It is radial distance between top land of the teeth and pitch circle. Normally addendum = 1 module. Dedendum (hf) : It is radial distance between bottom land of the teeth and pitch circle.

- 11. Nomenclature of Gear: Basics of Gears, 03/2023, Vishwas Mokashi Whole depth : It is radial distance between Addendum circle and dedendum circle. It is sum of Addendum and dedendum. Circular Pitch : It is the distance measured along the circumference of the pitch circle ,from point on one tooth to corresponding point on next tooth. Pressure Angle : It is the angle between the common normal to the two gear teeth at point of contact and common tangent to two pitch circles at pitch point. Pressure angle is the angle at which pressure from the tooth of one gear is passed on the tooth of another gear. 14.5°and 20°are standard pressure angle.

- 12. Working Gear Nomenclature: Basics of Gears, 03/2023, Vishwas Mokashi Backlash - Backlash is the amount by which the width of a tooth space exceeds the thickness of engaging gear tooth. In general, backlash in gears is play/clearance between mating teeth.

- 13. Gear Manufacturing Processes: Basics of Gears, 03/2023, Vishwas Mokashi METHODS: Broaching Shaping Milling Plastic Injection Molding Powder Metal Sintering Forging Casting Hobbing Hobbing: Generally gears are produced by hobbing. Gear hobbing is continuous indexing process in which both cutting tool(hob) and workpiece rotates in a constant relationship , while the hob is being feed into work. After one complete rotation of gear blank, the gear blank is feed horizontally towards the hob to cut next tooth depth. This process is repeated until the required depth is obtained.

- 14. Process Flow of Gear: Basics of Gears, 03/2023, Vishwas Mokashi Gears_-_How_its_Made.mp4

- 15. Gear Accuracy: Gear must work in transmitting rotation or power from one gear axis to another, efficiently and quietly. To improve gear accuracy is to improve the performance of a gear. Gear accuracy can be classified into three types; 1. Precision in involute tooth profile --- Profile deviation(error) 2. Precision in tooth face --- Lead deviation(error) 3. Precision in tooth positioning/ tooth trace --- a) Precision in pitch – Single pitch variation and total cumulative pitch variation b) Variation of position – Run out error Basics of Gears, 03/2023, Vishwas Mokashi

- 16. Gear Metrology: 1. Size inspection: a) Span measurement by span micrometer b) Bore and keyway measurement by gauges c) Symmetry, run out, face out and parallelism measurement. d) Worm gear tester - To measure tooth contact and backlash. Basics of Gears, 03/2023, Vishwas Mokashi 2. Composite inspection: In this method the work gear is rolled in tight double flank contact with master gear. No backlash is provided. The roll tester allow variation in the center distance during rolling. This variation in center distance will yield a ‘tooth to tooth’ and a ‘ total composite ’ indication that can be read on simple dial indicator or recorded graphically.

- 17. Gear Metrology: Lead and Profile Testing Basics of Gears, 03/2023, Vishwas Mokashi 3. Lead and profile testing Lead and profile testing is done on L&P tester. Internationally accepted prominently used standards are DIN, AGMA, JIS.

- 18. Terms in Lead and Profile Graph: Basics of Gears, 03/2023, Vishwas Mokashi Various characteristics identified for such a classification are called “Gear Errors”. Main categories of such characteristics are Tooth Profile / Form Errors , Pitch Errors , Lead / Helix Errors , Eccentricity GEAR ACCURACY Errors , Finish Errors , Cyclic errors, Rolling errors etc. We need to understand these to implement and build preventive measures in our manufacturing process design , selection of equipment and tooling's, selection of appropriate measurement method etc. for achieving appropriate class of gears. Symbol Nomenclature Definition fHα Profileangularerror Distance between two nominal profilesthat intersect theaverage profile at startandend points of theprofile range. Fα TotalProfile error Distance between two nominal profilesenclosed within the profile testrange. ffα Profile formerror Distance between two involutesof the actual basecircle thatenclose the actual involute profile within theprofileinspection range. fHβ Lead angularerror Distance between two nominal leads that intersectthe average lead at start and end points of the lead inspection range. Fβ Total lead error Distance between two nominal leadsenclosed within the leadtestrange. ffβ Lead form error Distance between two helical lines thatenclosethe actual lead enclose within the lead inspection range. fp Tooth to toothspacing Fp Total cumulativepitch variation Difference betweenthe themost positive and the most negative valueforall teeth Fr Radial runout Radialposition difference of a probe contacting allteeth at measuring diameter(pitch diameter).

- 19. Class of Accuracy Comparison: Basics of Gears, 03/2023, Vishwas Mokashi In DIN ( German Standards) lower the class higher the accuracy , where as in AGMA ( American Standards) lower class represents lower accuracy. The allowable Errors in equivalent class as represented in the comparative are not exactly same but near about. That means if drawing specifies class of accuracy as per AGMA we need to follow allowable errors as per AGMA and so on.

- 20. L&P Report Header: Basics of Gears, 03/2023, Vishwas Mokashi General Info Gear data

- 21. Profile Error Chart: Basics of Gears, 03/2023, Vishwas Mokashi

- 22. Profile Error Evaluation: Basics of Gears, 03/2023, Vishwas Mokashi Average value Nominal value as per DIN 3962 Observed class Required class

- 23. Basics of Gears, 03/2023, Vishwas Mokashi THANKS ! vsm_97@rediffmail.com