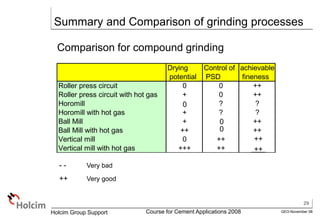

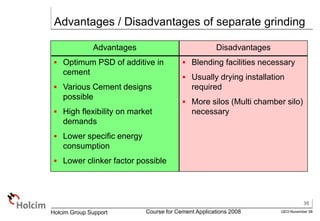

The document discusses different cement grinding systems and their effects on cement properties. It describes various grinding systems including ball mills, vertical mills, and roller presses. It explains how the grinding system and separator type influence particle size distribution, which impacts strength development and workability. Drying capacity is also an important process aspect, as insufficient drying can lead to cement hydration issues. The document compares compound and separate grinding, noting that compound grinding of materials with different grindabilities can affect the particle size distribution achieved.

![4

GEO-November 08

Holcim Group Support Course for Cement Applications 2008

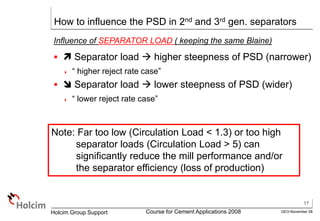

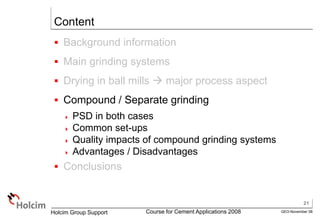

Background information

The grinding system (including separator type) is

influencing directly the Particle Size Distribution

(PSD)

Strength development

Workability

Drying = one of the main process parameters in

grinding

Effect on the setting behaviour (e.g. because of different

gypsum dehydration)

Insufficient drying capacity indicated by low mill exit

temperature (< 85 [oC]) or too high exit gas dew points

(> 60 [oC]) can lead to cement hydration (use of wet

additives)](https://image.slidesharecdn.com/021500geomolean-220904194107-b056ed51/85/CEMENT-021500geomolean-ppt-4-320.jpg)

![7

GEO-November 08

Holcim Group Support Course for Cement Applications 2008

Ball Mill EDM (End Discharge Mill)

Clinker Gypsum

Min.

Comp.

[l/h]

[kW]

[l/h]

[t/h]

[°C]

[mbar] [°C]

[t/h] [t/h] [t/h]

[t/h] [t/h] [t/h]

[%]

[%]

[%]

[%]

[%]

[%]

[t] [t] [t]

[°C]

[l/h]

Grinding

aid

[1/min]

[°C]

[kW]

[mbar]

[°C]

[mbar]

[kW]

[mbar]

[°C]

[1/min]

[°C]

[°C]

[°C]

[1/min]

[m3/h] [mg/m3]

Sollwerte

Prozesswerte

[t/h]

[t/h]

[1/min]

[°C]

Product

Process

parameters](https://image.slidesharecdn.com/021500geomolean-220904194107-b056ed51/85/CEMENT-021500geomolean-ppt-7-320.jpg)

![10

GEO-November 08

Holcim Group Support Course for Cement Applications 2008

VRM (vertical roller mill) for cement grinding

grinding aid DEG

[t]

[kW]

[t/h]

[mbar]

[°C]

[%] [l/min]

[t/h] [t/h]

[%]

[cm2

/g]

sampler

[%R]

[l/h]

[mbar]

[°C]

[kW] [%]

[°C]

Hot gas

[t]

[t] [%] [%] [bar]

[mbar]

[min-1]

[min-1]

[l/h]

to cement

silo

fresh air

Clinker Gypsum

In blue = process

parameters](https://image.slidesharecdn.com/021500geomolean-220904194107-b056ed51/85/CEMENT-021500geomolean-ppt-10-320.jpg)

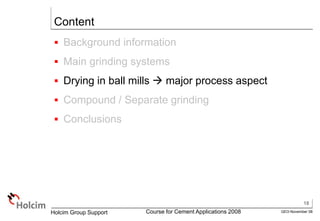

![19

GEO-November 08

Holcim Group Support Course for Cement Applications 2008

Drying in Ball Mill - Bottlenecks

Fresh air

Fresh air

Moist additive

Hot clinker

Hot gas

H2O

Product

Air

Dust ladden air

H2O

Hot air

70

80

90

100

110

120

Product

temp. [°C]

Mill length

grinding

heat

water

evaporation

Cooling by

water injection

Finish

Product

Mill

exhaust

air

< 300 °C

> 100 °C

Recirculating air

Drying

Compartment?

Ball Mills as limited in drying capacity. An EDM can

dry max. 4% feed moisture even having a HGG!](https://image.slidesharecdn.com/021500geomolean-220904194107-b056ed51/85/CEMENT-021500geomolean-ppt-19-320.jpg)

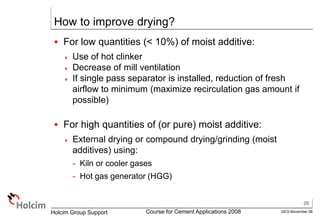

![22

GEO-November 08

Holcim Group Support Course for Cement Applications 2008

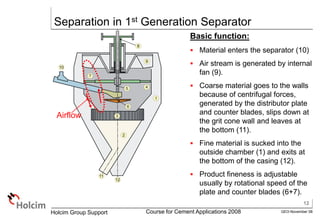

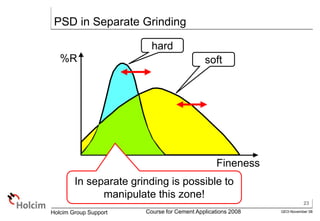

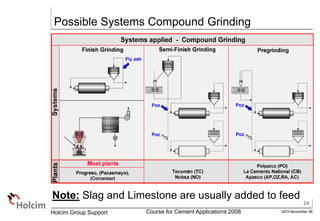

PSD in Compound Grinding

Compound grinding of

materials with different

grindabilities is affecting

the product PSD

CC01-005.dsf Kma 06.06.00

[%R]

acc.

[cm2/g]

Blaine

mill length [m]

longitudinal sieving graph

GA

[g/t]

°C

[m3/h]

[%]

[kW]

[t/h]

[%R,cm2/g]

[°C]

[°C]

[mbar]

[m3/h]

separator tailings

[t/h]

[°C]

[%R]

Fresh feed

[t/h]

[%H2O]

[°C]

[% comp.]

acc.

[mm]

[m]

particle size

1 10 25 50

Blaine: Some of the

components achieve the

necessary fineness

faster inside the mill

(could be pozzolana,

limestone, fly ash)

Waste of energy

Low flexibility in terms

of influencing the PSD

Cumulated

residues](https://image.slidesharecdn.com/021500geomolean-220904194107-b056ed51/85/CEMENT-021500geomolean-ppt-22-320.jpg)

![25

GEO-November 08

Holcim Group Support Course for Cement Applications 2008

Common Systems for Separate Grinding

Clinker Gypsum

Min.

Comp.

[l/h]

[kW]

[l/h]

[t/h]

[°C]

[mbar] [°C]

[t/h] [t/h] [t/h]

[t/h] [t/h] [t/h]

[%]

[%]

[%]

[%]

[%]

[%]

[t] [t] [t]

[°C]

[l/h]

Grinding

aid

[1/min]

[°C]

[kW]

[mbar]

[°C]

[mbar]

[kW]

[mbar]

[°C]

[1/min]

[°C]

[°C]

[°C]

[1/min]

[m3/h] [mg/m3]

Sollwerte

Prozesswerte

[t/h]

[t/h]

[1/min]

[°C]

Product

grinding aid DEG

[t]

[kW]

[t/h]

[mbar]

[°C]

[%] [l/min]

[t/h] [t/h]

[%]

[cm2

/g]

sampler

[%R]

[l/h]

[mbar]

[°C]

[kW] [%]

[°C]

Hot gas

[t]

[t] [%] [%] [bar]

[mbar]

[min-1]

[min-1]

[l/h]

to cement

silo

fresh air

Clinker Gypsum

VRM for

cement & slag

grinding

BM for cement

grinding](https://image.slidesharecdn.com/021500geomolean-220904194107-b056ed51/85/CEMENT-021500geomolean-ppt-25-320.jpg)

![27

GEO-November 08

Holcim Group Support Course for Cement Applications 2008

Quality Impacts of Compound Grinding BM

Problem Solution

Partly hydration of additive (slag);

loss of strength

Influence on sulphate due to humid

atmosphere in mill

Separate drying

Installation of hot gas generator and

drying chamber

Avoid dew point > 60 [°C]

PSD not optimum

‘Steepness’ (n) of PSD too high/low

Change of circulation load*

Too low n’: increase circ. load

Too high n’: decrease circ. load

New Separator?

Strength development insufficient

Workability not acceptable

Setting behaviour does not meet

requirements

Adapt mill exit temperature if related

to gypsum

*Only in certain range possible](https://image.slidesharecdn.com/021500geomolean-220904194107-b056ed51/85/CEMENT-021500geomolean-ppt-27-320.jpg)

![28

GEO-November 08

Holcim Group Support Course for Cement Applications 2008

Quality Impacts of Compound Grinding VRM

Problem Solution

Partly hydration of additive (slag);

loss of strength

Influence on Sulfate due to humid

atmosphere in mill

Increase fresh air (if possible)

Avoid dew point > 60 [oC]

Install Hot gas Generator

Particle Size Distribution (PSD) not

optimum

‘Steepness’ of PSD too high/low

Change of

Air Flow

Roller Pressure

Bed depth

Separator

Strength development insufficient

Workability not acceptable

Setting behaviour does not meet

requirements

Adapt mill exit temperature if related

to gypsum](https://image.slidesharecdn.com/021500geomolean-220904194107-b056ed51/85/CEMENT-021500geomolean-ppt-28-320.jpg)

![32

GEO-November 08

Holcim Group Support Course for Cement Applications 2008

Conclusions

In BM circuits the possibilities of influencing the PSD are

limited and very much depending on the separator type

The Vertical Roller mill is well suited for compound or

separate grinding

high flexibility for modifying cement properties

high drying capacity

Too low mill exit temperatures (< 85 [oC]) or dew point >

60 [oC] during compound grinding (e.g. caused by wet

slag) can lead to process and quality problems

Separate grinding gives more flexibility in product

design, product optimisation and reaction on quality

variations of clinker or additive](https://image.slidesharecdn.com/021500geomolean-220904194107-b056ed51/85/CEMENT-021500geomolean-ppt-32-320.jpg)