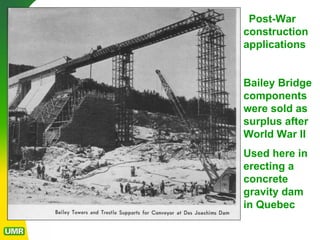

The document outlines the history and development of the Bailey bridge, highlighting its crucial role in WWII and versatility for post-war construction. Designed for easy transport and assembly, the Bailey bridge significantly aided military operations, with notable endorsements from military leaders like Field Marshal Montgomery and General Eisenhower. Today, its components are still used in various engineering applications worldwide, with modern firms continuing its legacy.