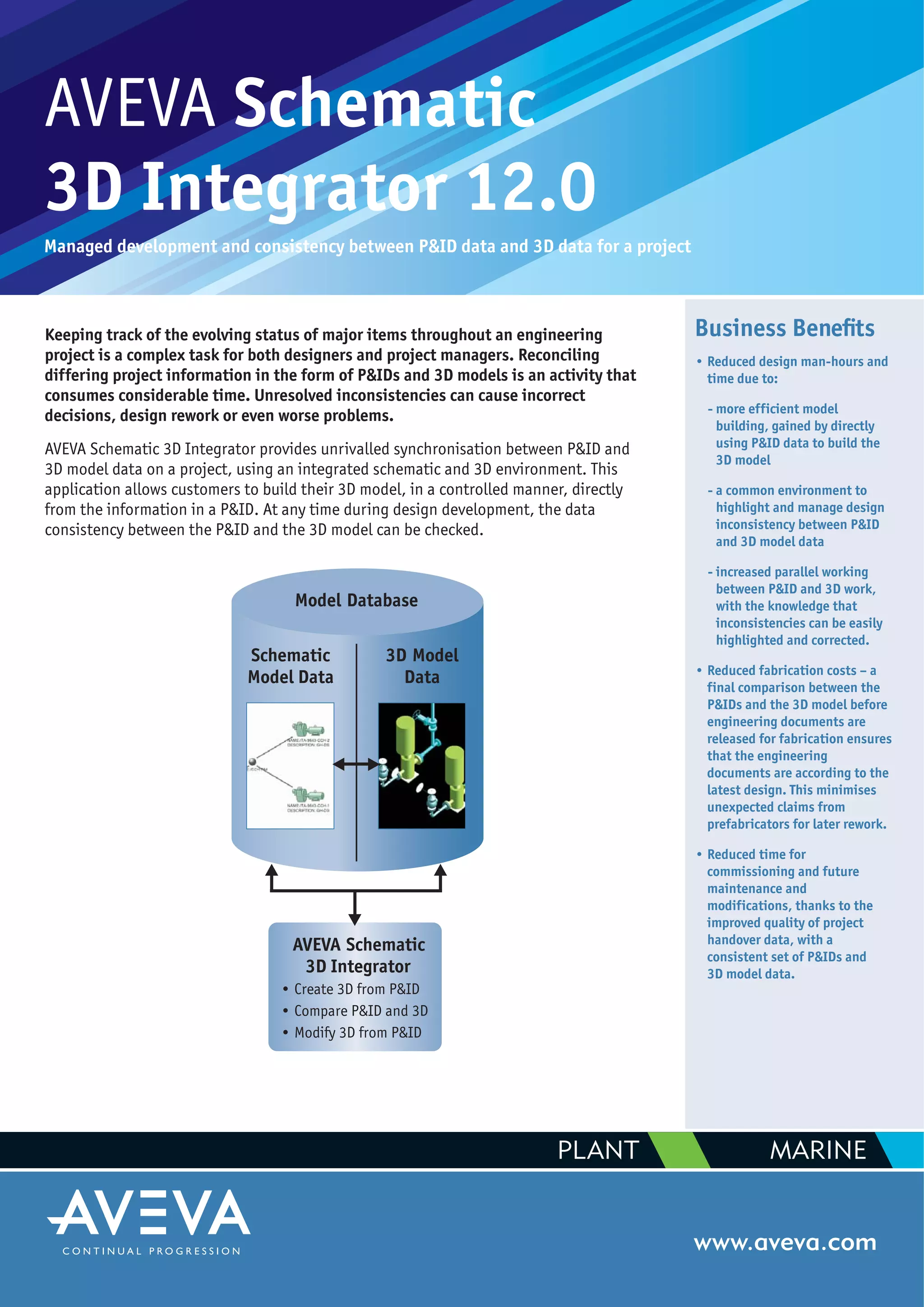

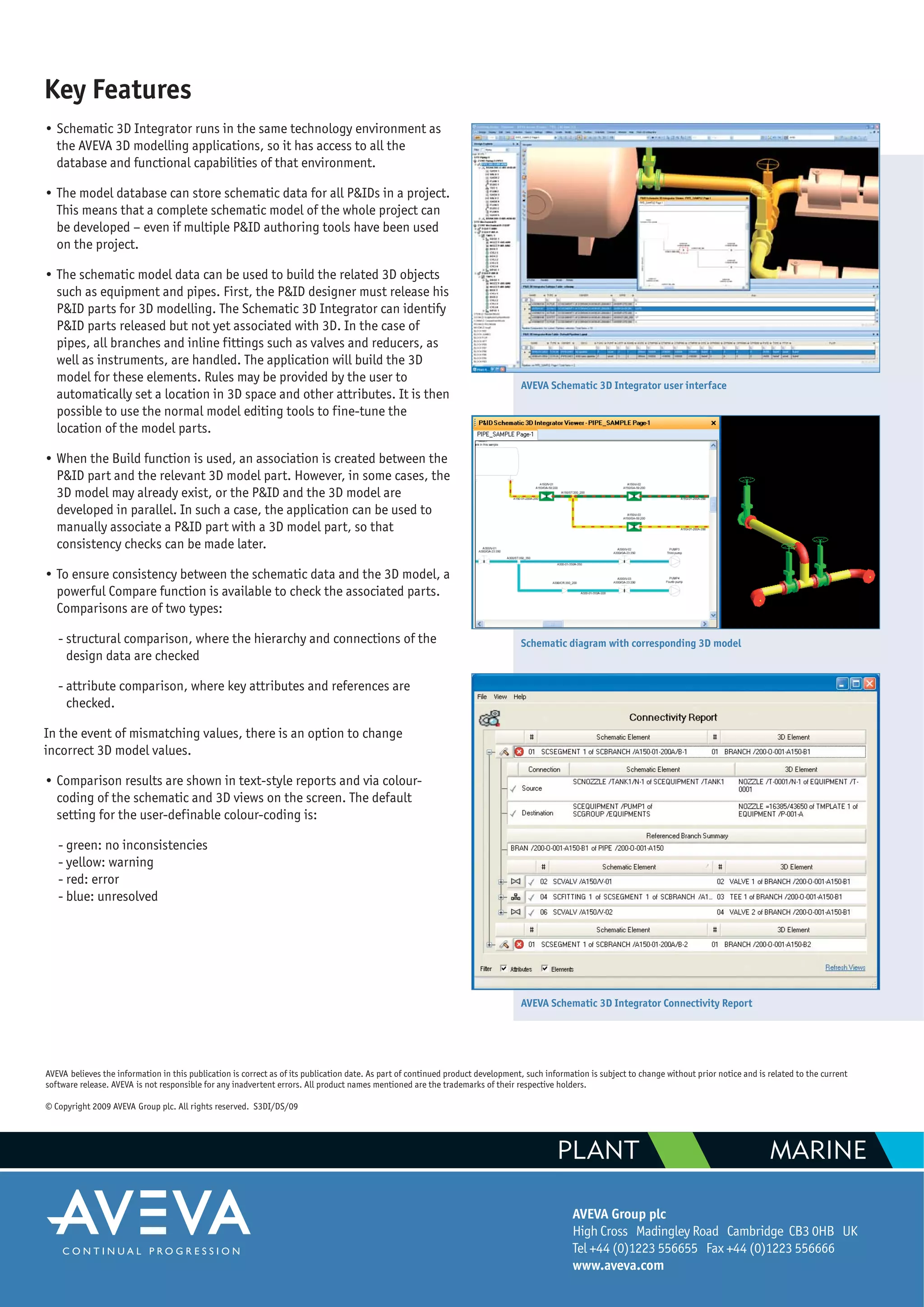

AVEVA Schematic 3D Integrator software allows users to manage consistency between piping and instrumentation diagrams (P&IDs) and 3D models during engineering projects. It builds 3D models directly from P&ID data in a controlled manner and allows users to check for inconsistencies between the diagrams and models at any time. This reduces design time and costs by enabling more efficient model building and highlighting inconsistencies for easy correction.