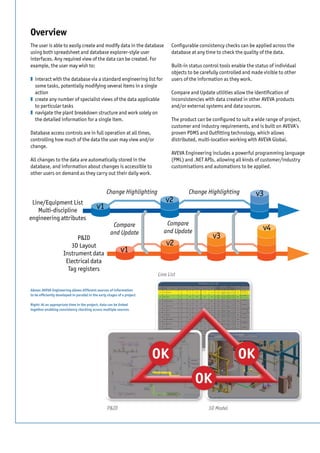

AVEVA Engineering enables multi-disciplinary engineering teams to collaboratively develop and manage project engineering data in a centralized database. It allows each discipline to control its own data for items while providing visibility of full data to other teams. The software automatically records changes to the data and allows users to highlight and view modifications. It also generates reports from the database and checks for data inconsistencies across engineering, 3D, and schematic documents.