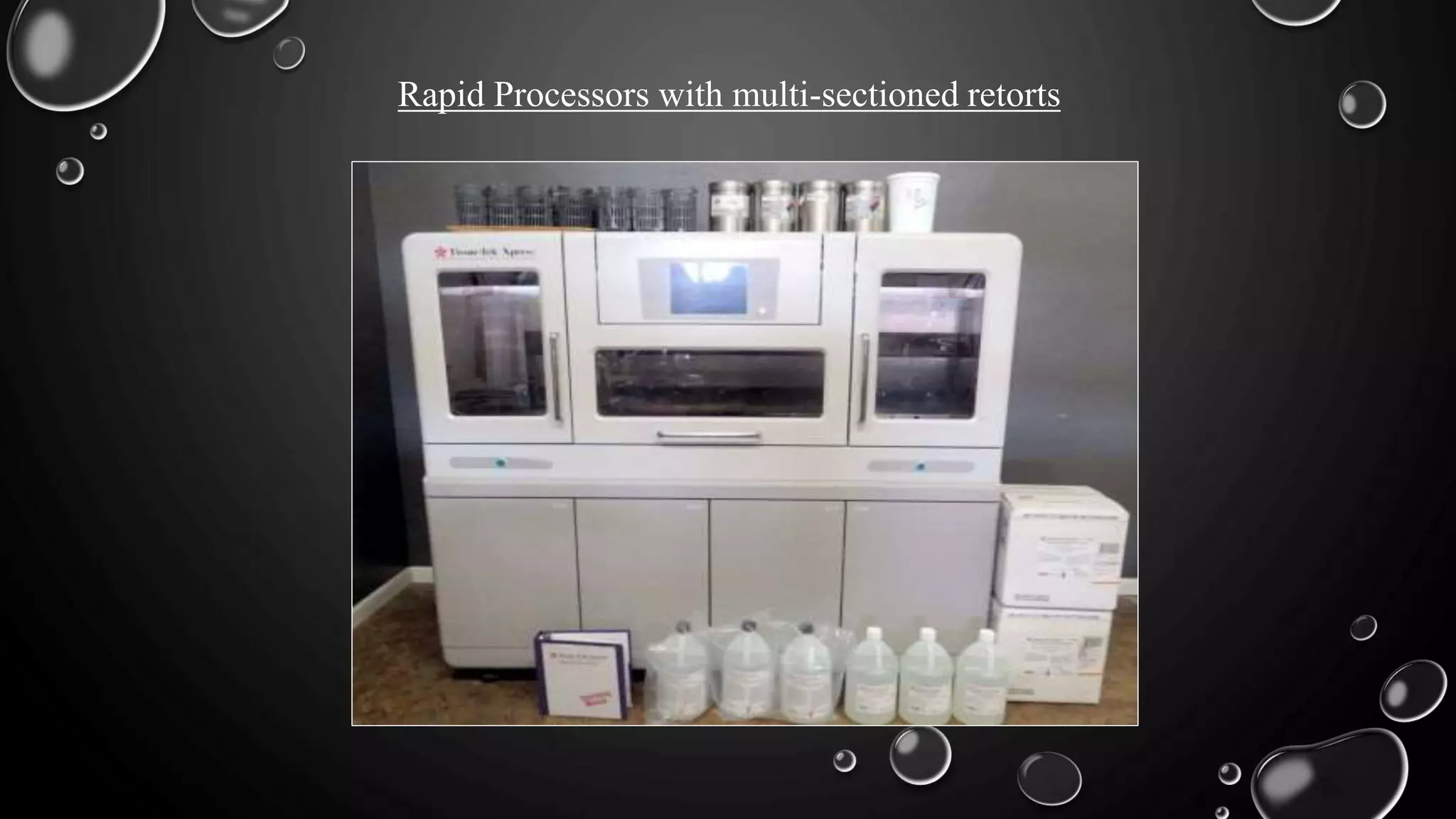

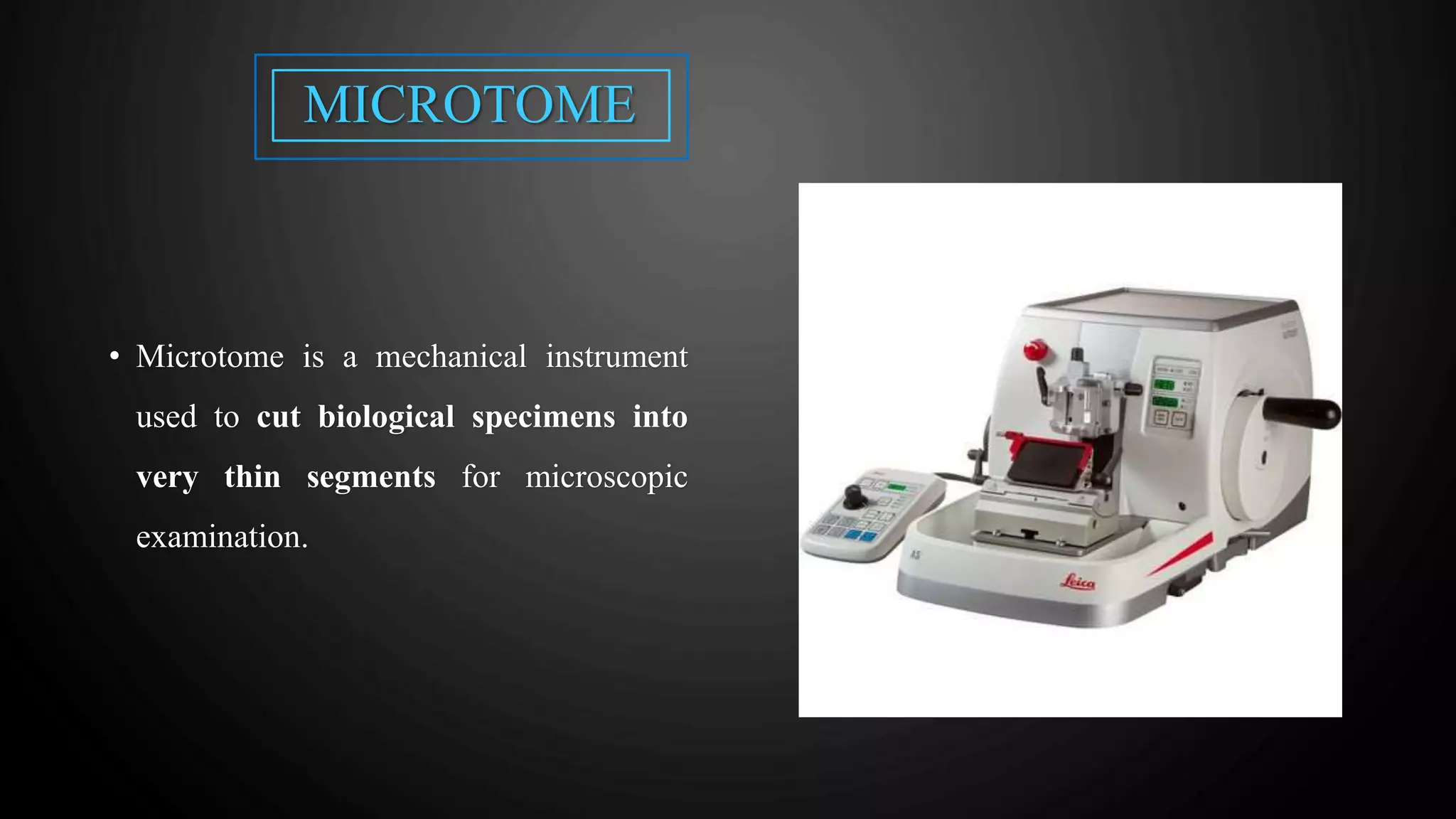

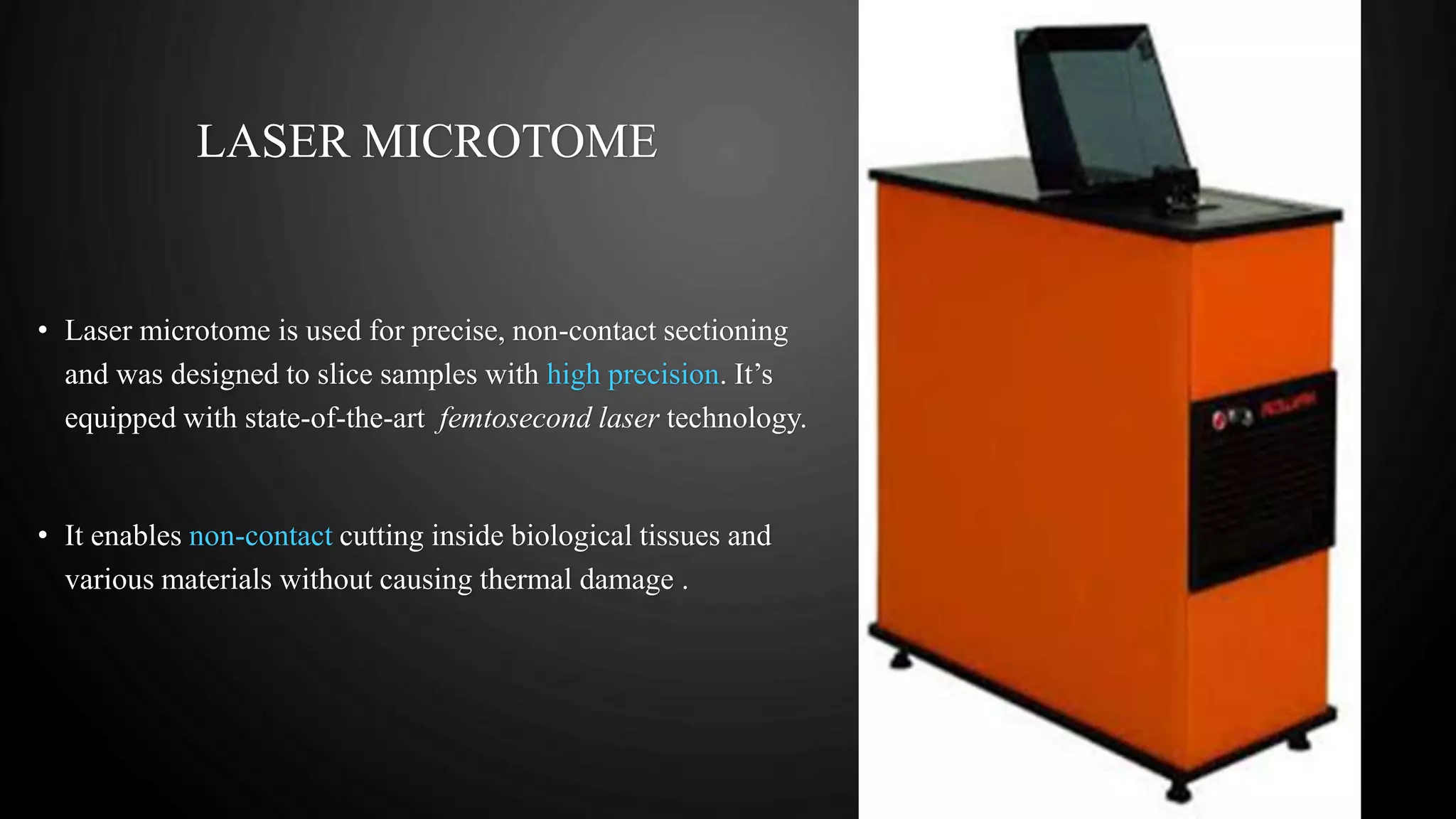

The document discusses various automated techniques used in histopathology. It describes automated tissue processors that use either tissue transfer systems or self-contained fluid exchange to process tissue through a series of solutions. Microwave and rapid processors are also discussed as alternatives that can significantly reduce processing time. The document also mentions automated tools for tasks like tissue microarrays, embedding, sectioning with microtomes and cryostats. Overall, the key benefits of automation include improved efficiency, customized schedules, reduced processing time and safer handling of chemicals.